Wear assembly

a technology of wear members and wear parts, applied in the field of wear components, can solve the problems of reducing the service life of wear components, so as to maximize the potential carrying weight of buckets, reduce the weight of wear components, and facilitate replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

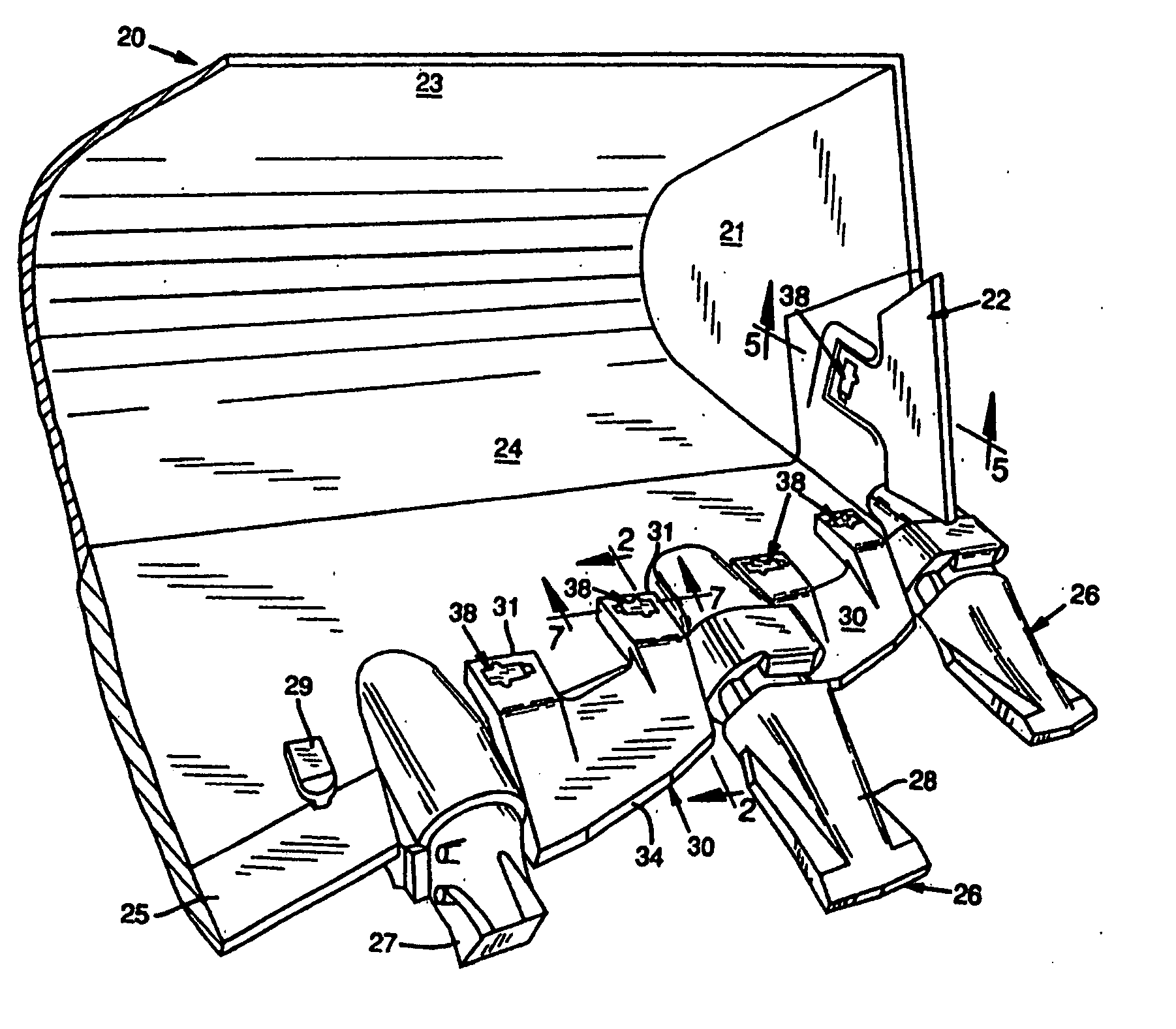

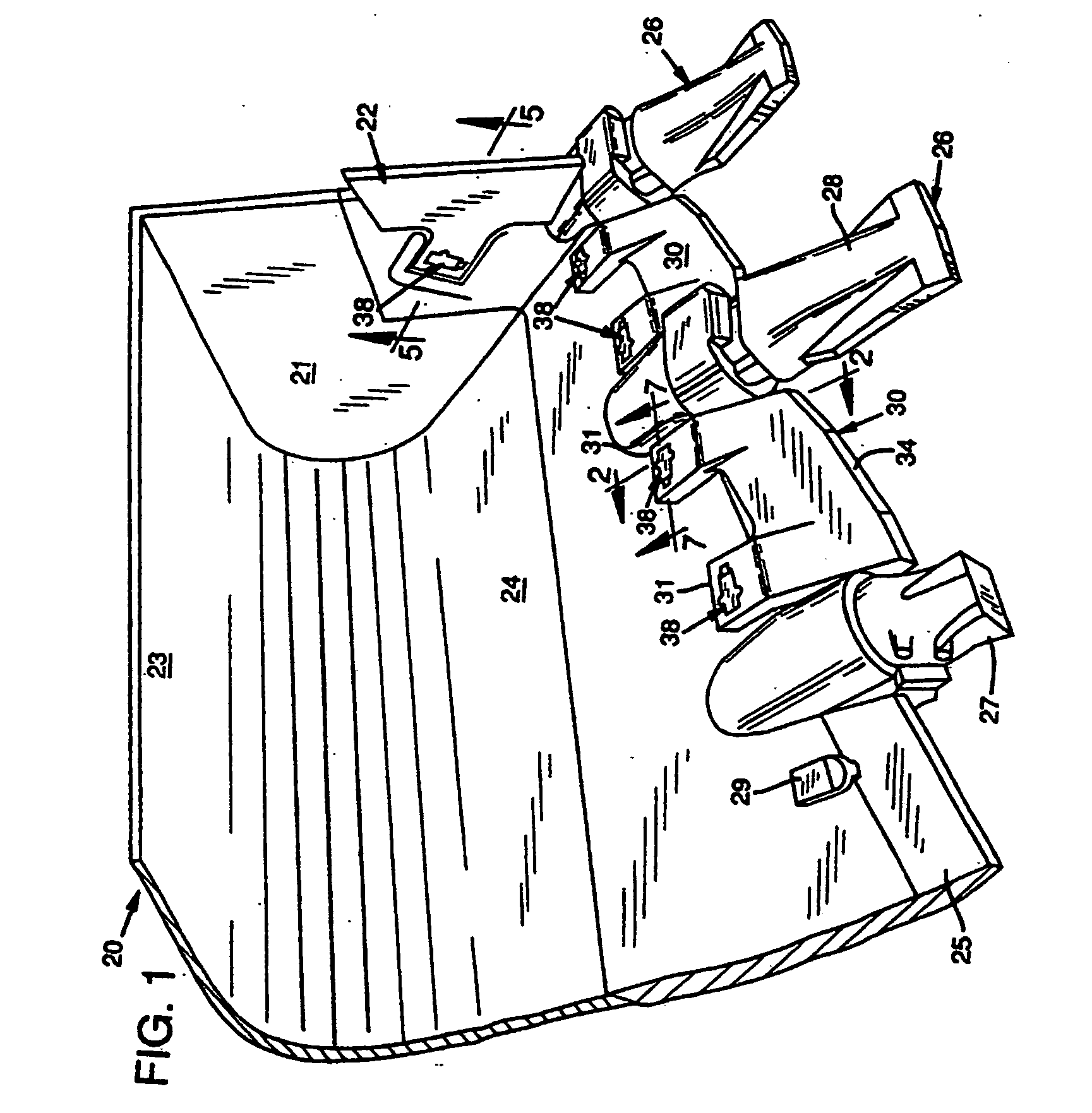

[0021] With reference to FIG. 1, numeral 20 designates generally a bucket having sidewalls or wings as at 21 equipped with a forwardly-facing protector 22, and a rear wall 23 merging into a bottom wall 24. The bottom wall 24 terminates in a forwardly positioned lip 25. The sidewalls and lip form a leading edge to the bucket. This is, of course, simply one example of an excavator which can be provided with a wear assembly in accordance with the present invention. The present invention could be used with other kinds of buckets or other digging equipment (e.g., dredge cutterheads).

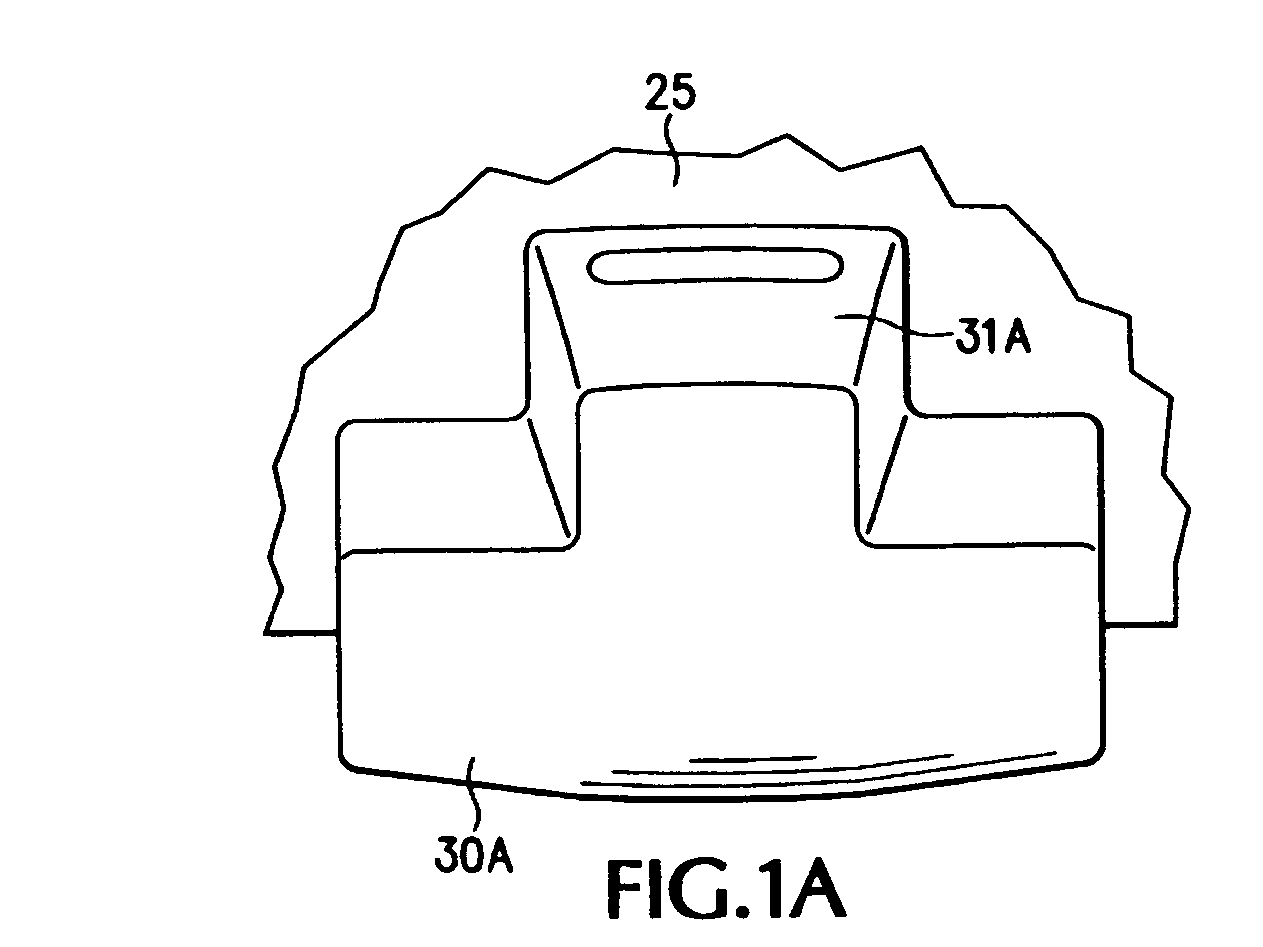

[0022] The lip 25 is equipped with transversely spaced-apart excavating teeth generally designated 26 (see the lower right), each of which preferably includes an adapter 27 fixed to the lip 25 and a point or tip 28 releasably mounted on each adapter 27. The portions of the lip 25 between the teeth are protected by wear members 30 mounted to the lip through cooperation with upstanding bosses 29 (see the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com