Adjustable weight putter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

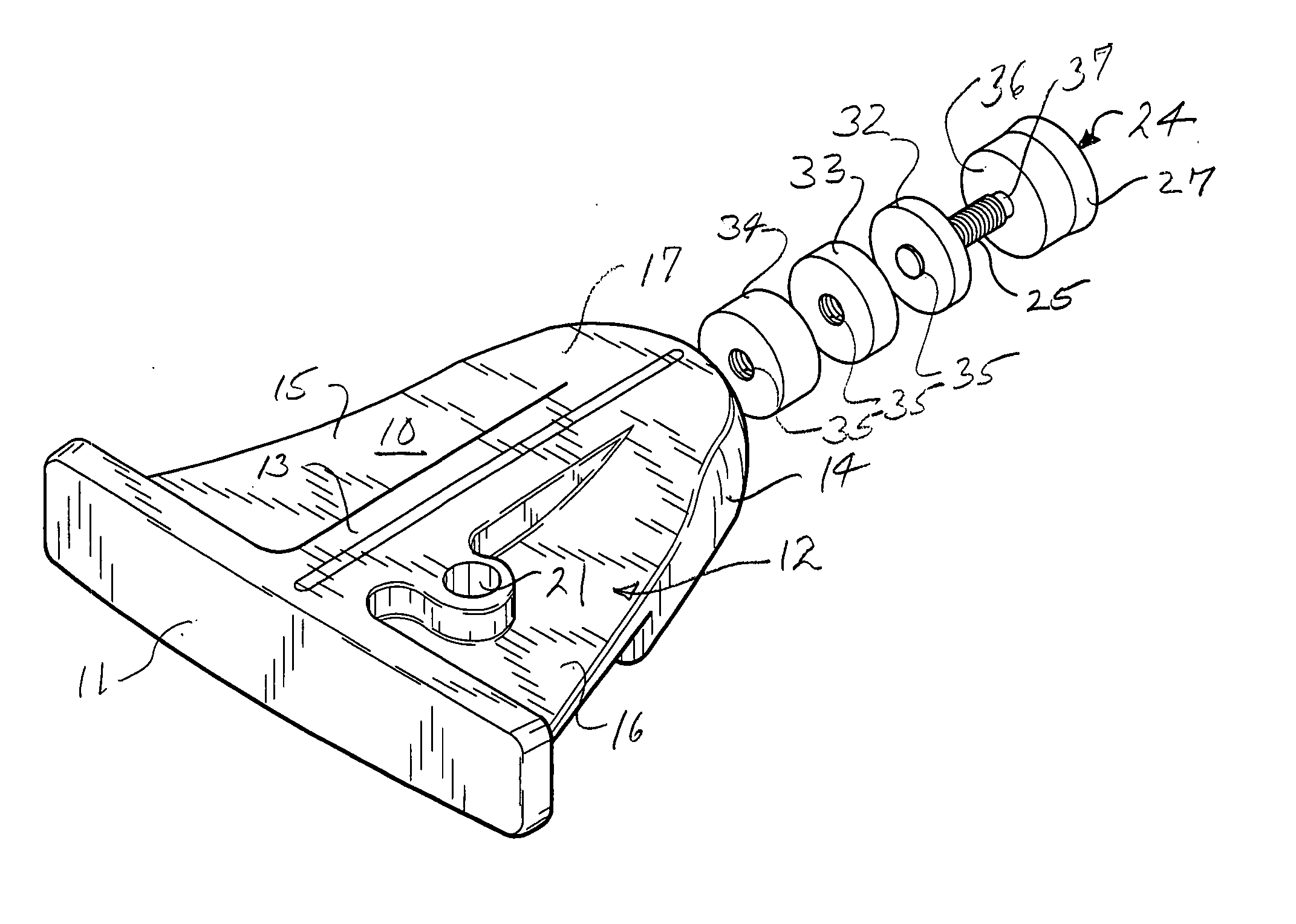

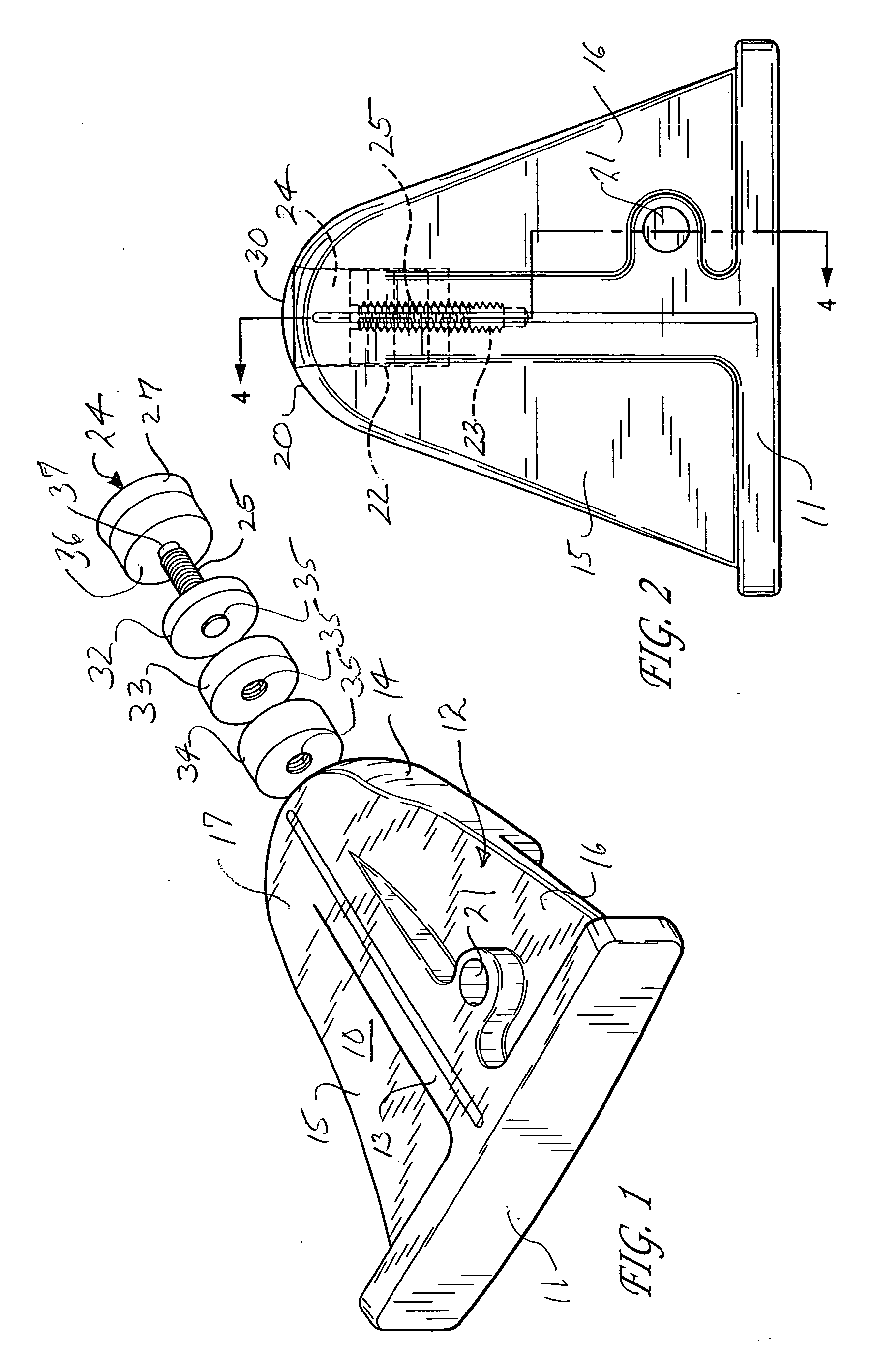

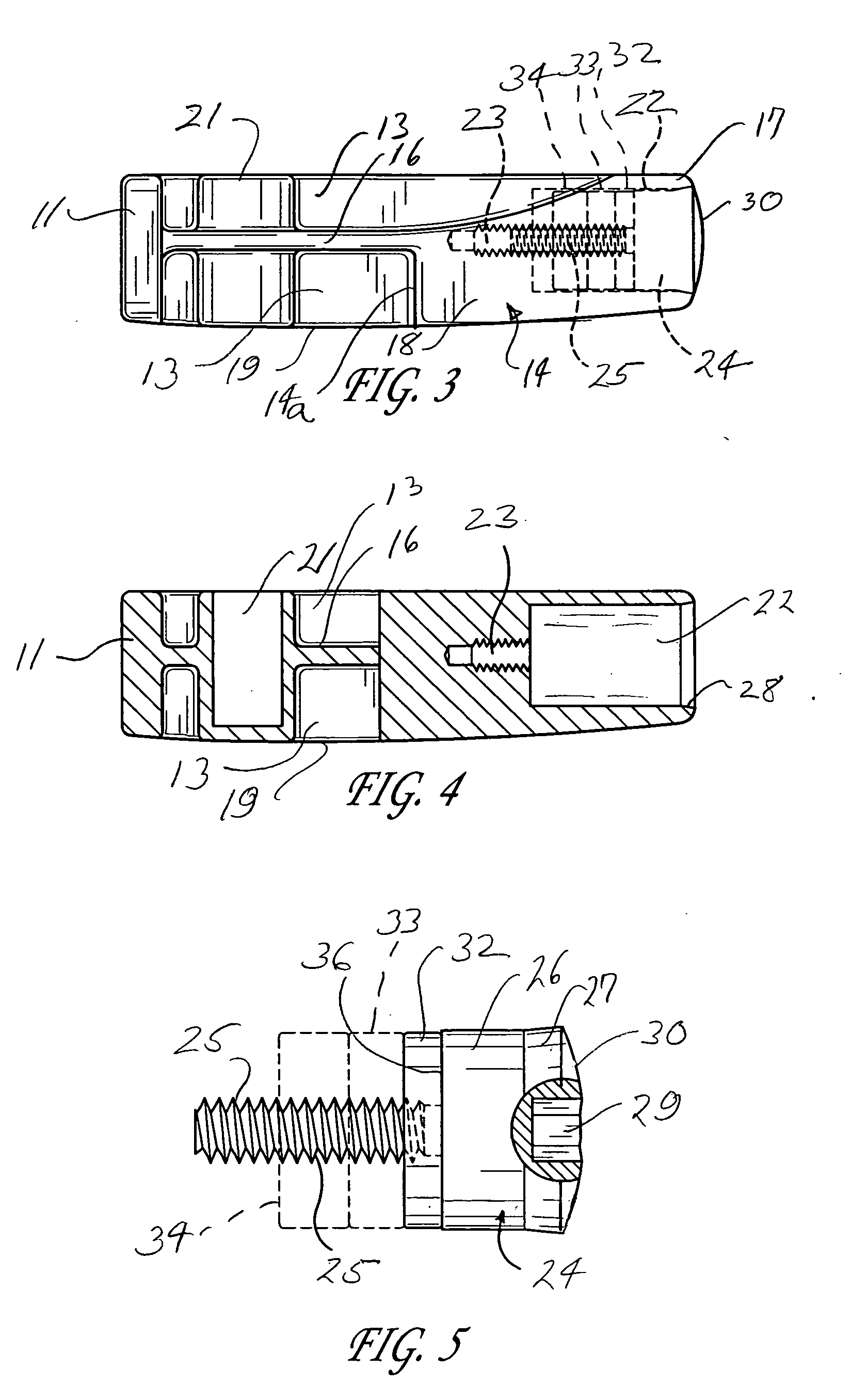

[0013] Referring now the drawings, the reference numeral 10 designates generally a putter head which is comprised of a ball-striking face 11 and an extended body portion 12 comprised of a stem 13, a body end portion 14, and gussets 15, 16 which extend along opposite sides of the stem 13 and join the ball-striking face 11 with the back portion 14 of the body.

[0014] Although specific dimensions of the putter head can vary, USGA rules require that the length of the putter (in the ball-striking direction) be less than the width of the ball-striking face. For long-shafted putters, it may be desired to have a larger putter head than for short-shafted putters. In all cases, however, the length-width relationship specified by the USGA rules must be observed. In typical embodiments of the invention, the face width of the putter may be around 4.25 inches, for a short-shafted putter and around 5.00 inches for a long-shafted putter, with the body length preferably being between 85 and 90% of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com