Tiltsensor

a tilt sensor and tilt technology, applied in the field of high-, can solve the problems of over-exceeding the measuring range, affecting the accuracy of measurement results, and the effort involved in the adjustment of the installation of a single tilt sensor, and achieving the effect of high resolution and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

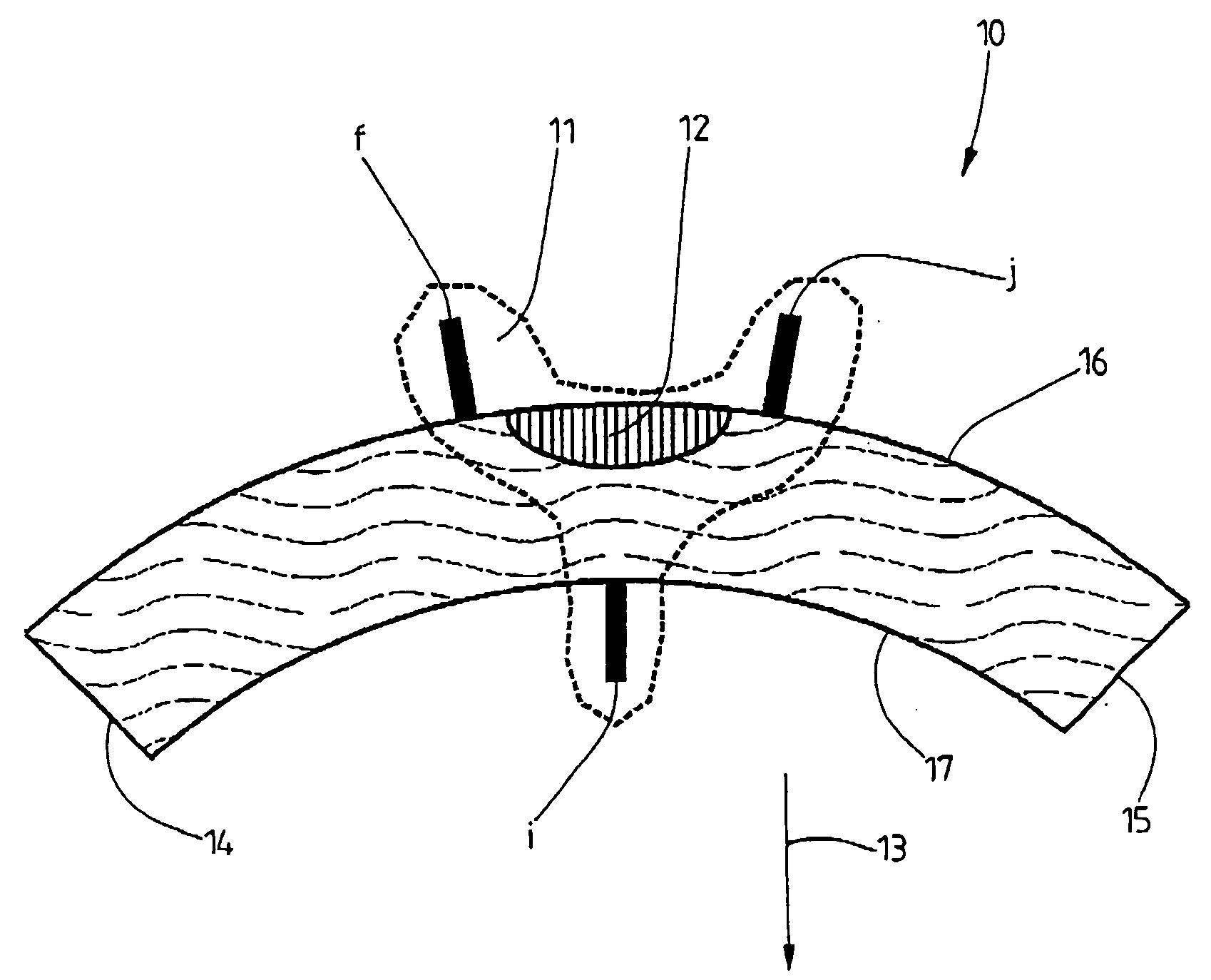

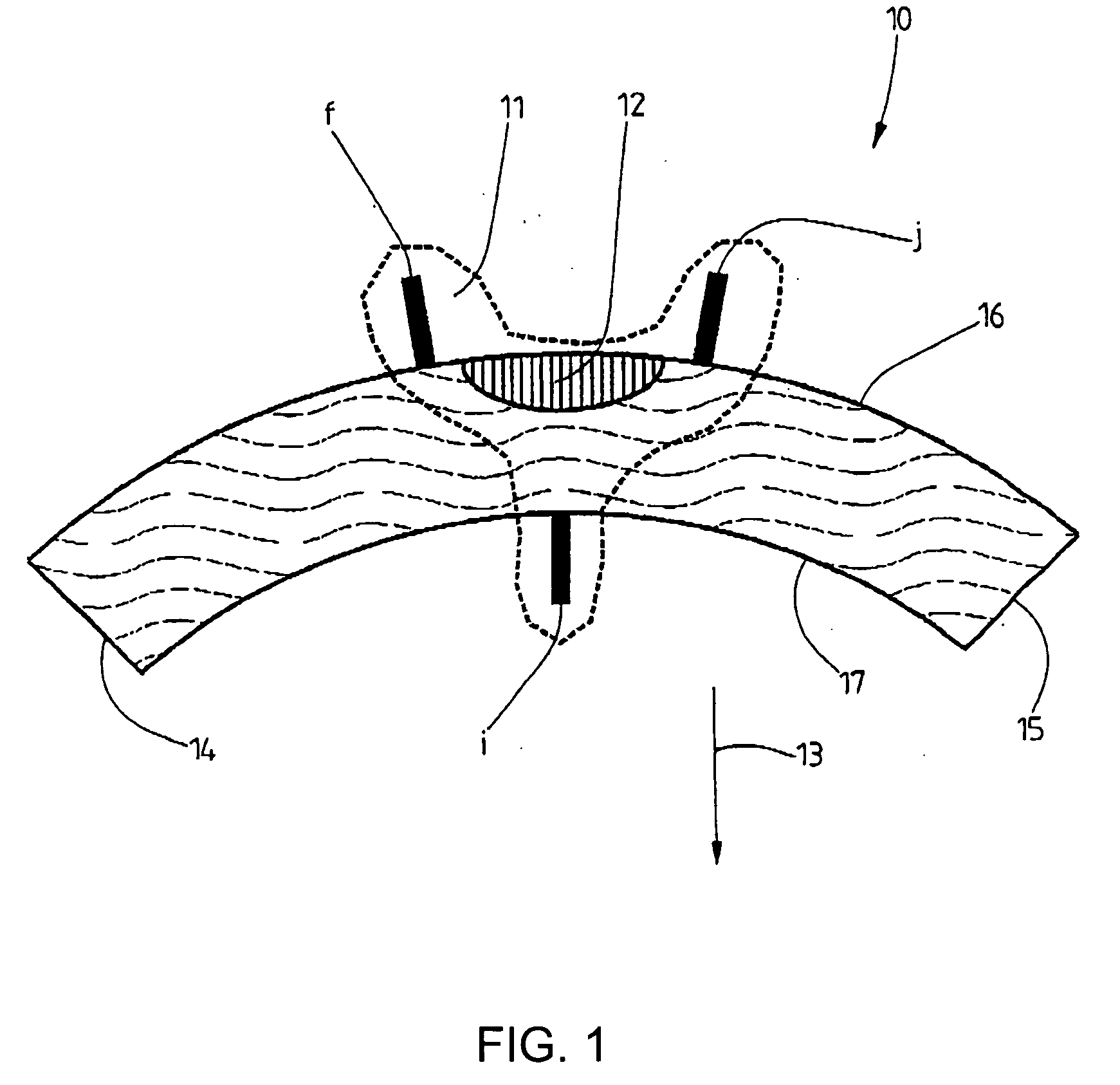

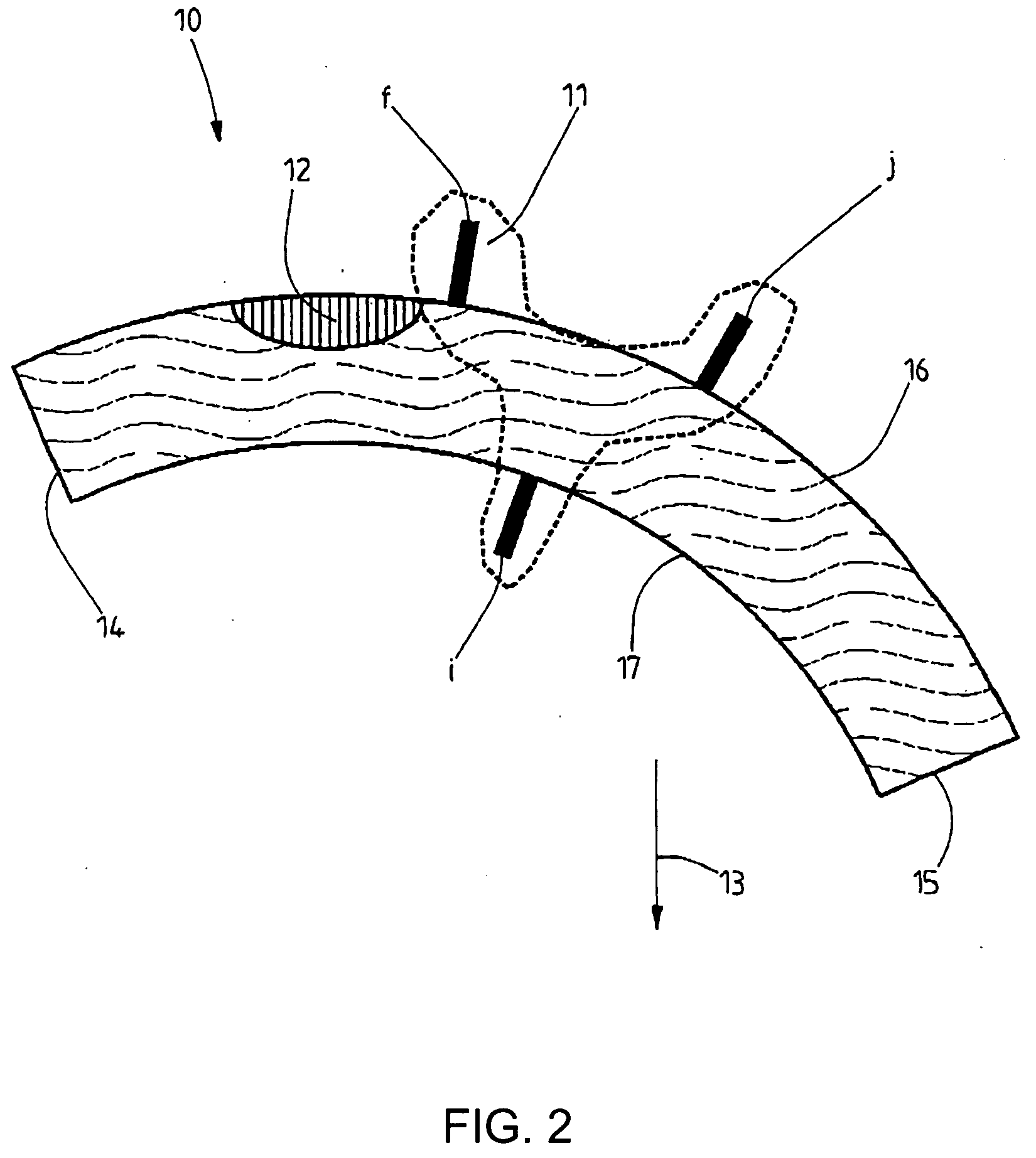

[0041] A conventional tiltsensor employing a spirit level 10 has one electrode configuration 11 comprising three electrodes f, i and j. The spirit level 10 is curved to correspond to an arc of a circle and is filled with an electrolytic liquid. The spirit level 10 also contains a small gas bubble 12 whose liquid buoyancy causes it to migrate to the highest position of the spirit level 10 and maintain its position there. In the drawing according to FIG. 1, the spirit level 10 is aligned with respect to the plumb direction (arrow 13) such that the gas bubble 12 maintains approximately the same distance to each end 14, 15 of the spirit level. This plumb-adjusted sensor position corresponds to its initial position after installation for monitoring movements of objects.

[0042] As a result of its curved shape, the spirit level 10 has a top, outer side 16 and an opposite bottom, inner side 17. Arranged on the outer side 16 are the two electrodes f and j, which are spaced apart from each ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com