Soft-coated glass pane refrigerator door construction and method of making same

a refrigerator door and glass pane technology, applied in the field of door construction, can solve the problems of affecting the customer's ability to view the products in the display case, slipping hazards, and condensation frequently occurring on the glass pane of the door, and achieve the effects of low emissivity, low emissivity, and low emissivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

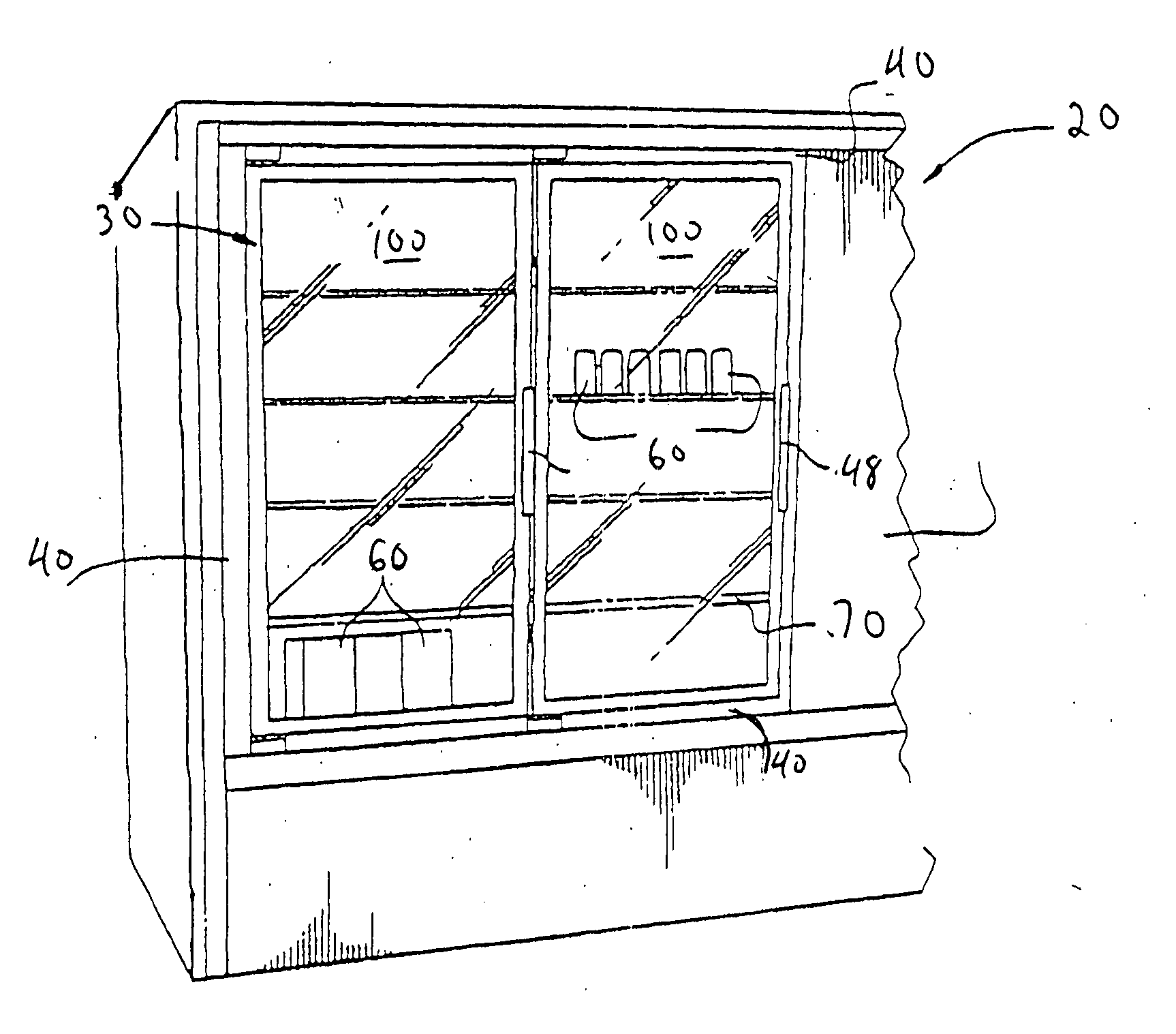

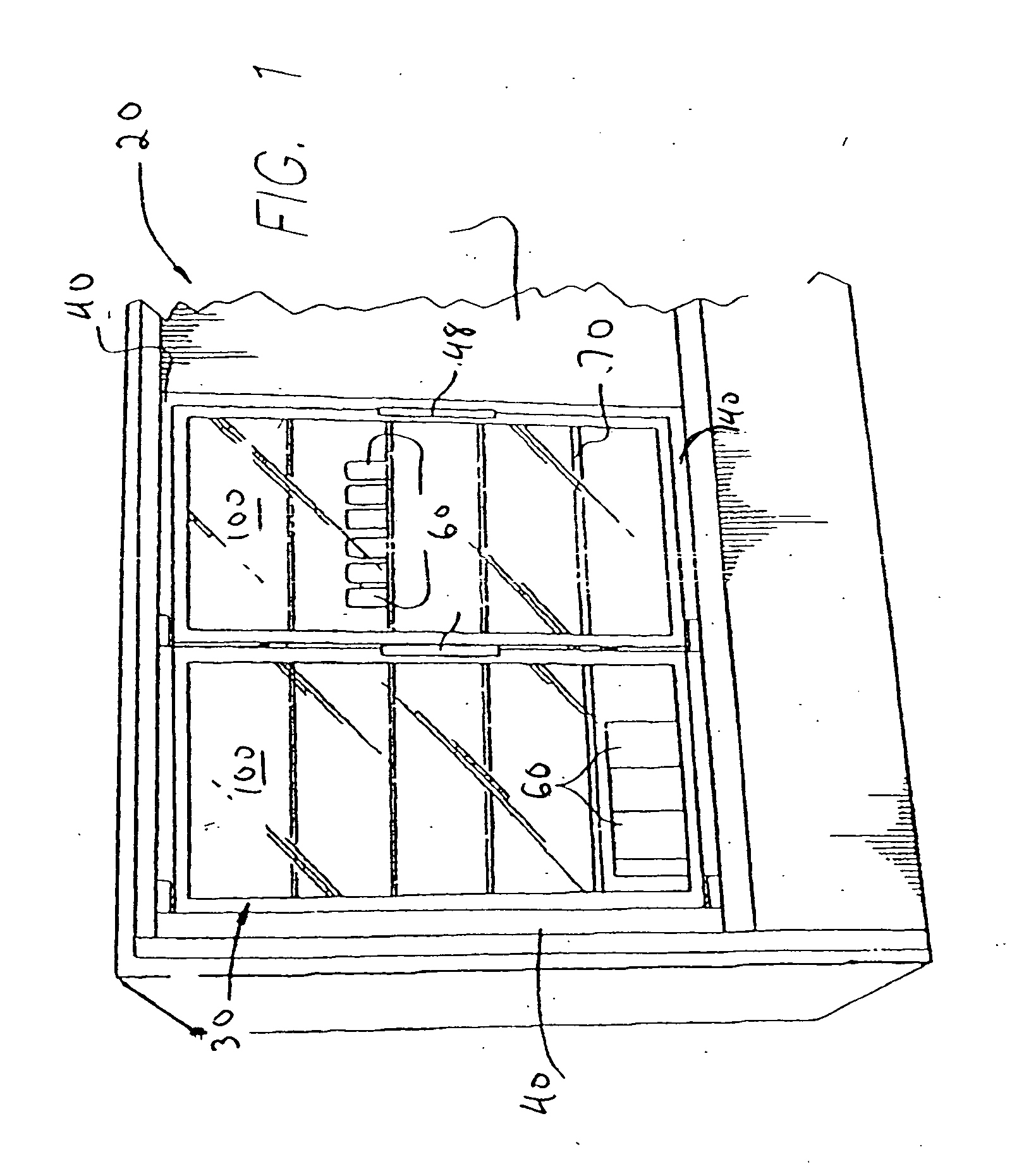

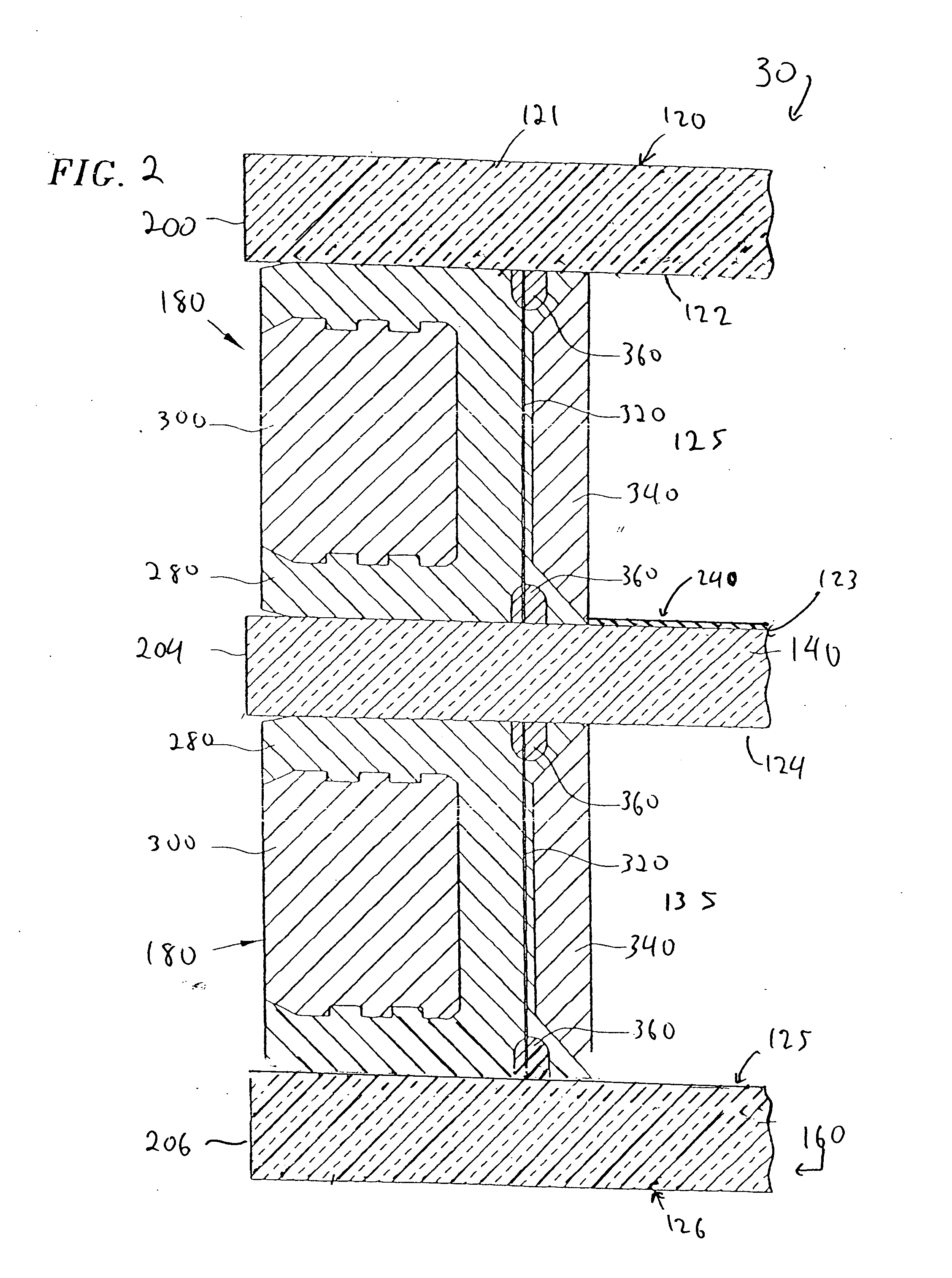

[0006] In accordance with a first aspect of the present invention, a door for a refrigerated display case is provided. The door comprises a glass panel having first and second surfaces, wherein the first surface is coated with a low emissivity soft coating. In describing the glass panels, the surface closest to the customer, i.e. the outside, is referred to as the first surface, and the inner surface is referred to as the second surface. The coated surface preferably has an emissivity of not more than about 0.1. An emissivity of not more than about 0.05 is more preferable and an emissivity of not more than about 0.03 is especially preferred.

[0007] In accordance with a second aspect of the present invention, a refrigerated display case having three glass panels is provided. Each panel has first and second surfaces, and one of the surfaces is coated with a low-emissivity soft coating. The coated surface preferably has an emissivity of not more than about 0.1. An emissivity of not mor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com