Fire door core assembly

a core and fire door technology, applied in the field of doors, can solve the problems of inability to withstand the hose stream test in a 45-minute fire test, more difficult or impossible, and more expensive construction of higher rated fire doors, and achieve the effect of convenient and effective lamina

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

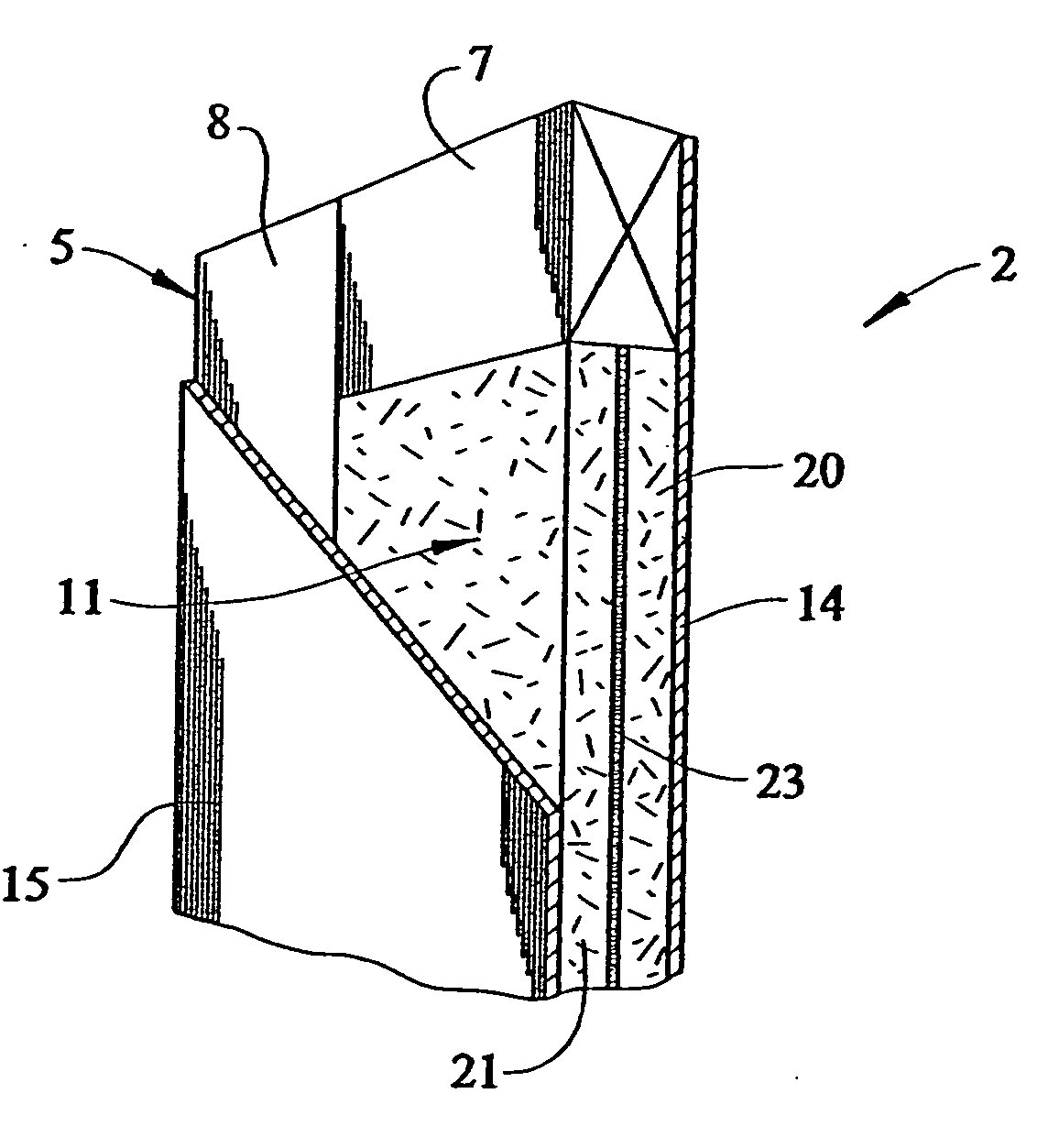

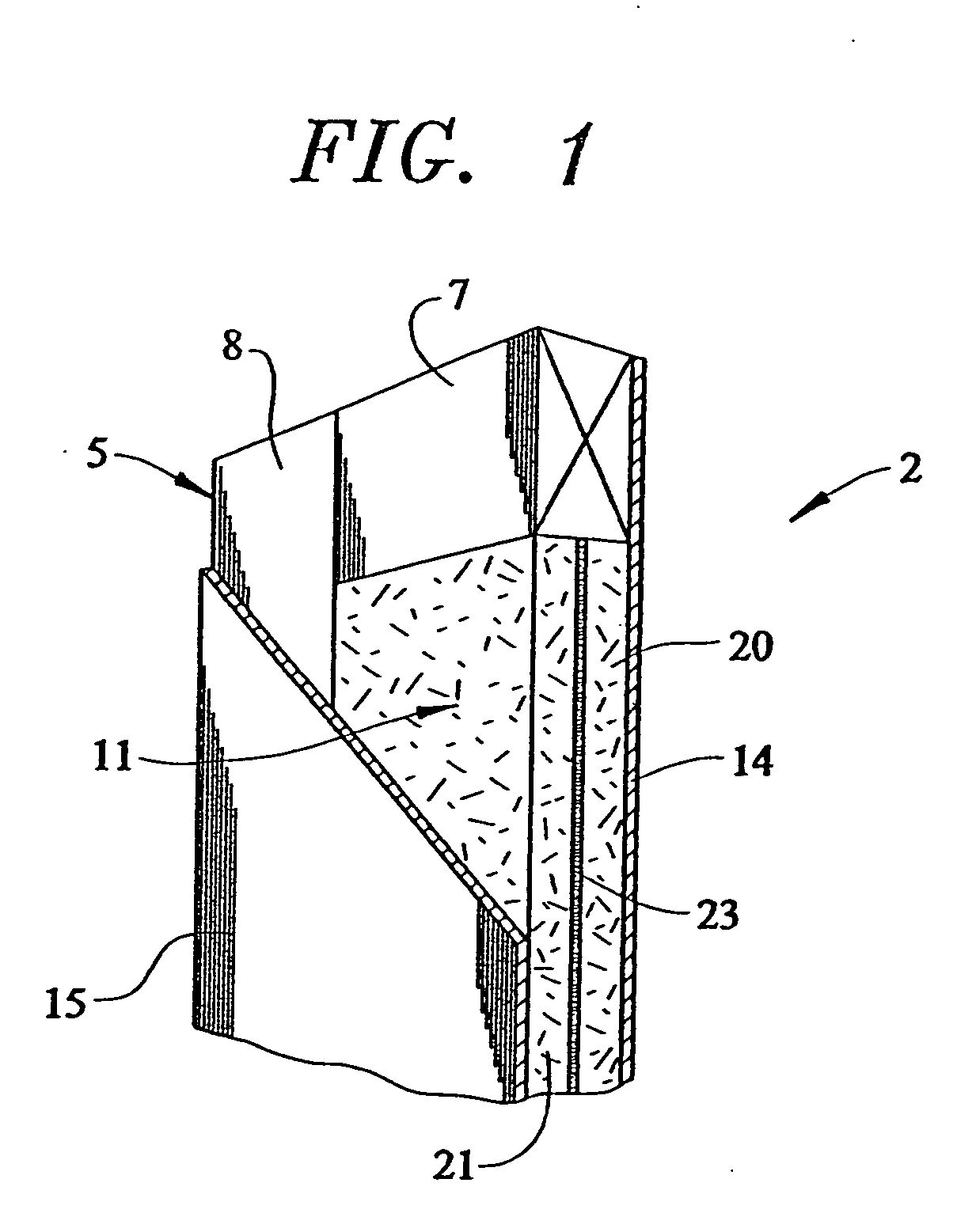

[0013] With initial reference to FIG. 1, a fire door constructed in accordance with the present invention is generally indicated at 2. As shown, door 2 includes an outer peripheral frame 5, constituted by interconnected rails, an upper one of which is shown at 7, and stiles, one of which is shown at 8; a core 11; an inner door skin 14; and an outer door skin 15. In general, the above construction of door 2, with the exception of the particulars of core 11, is known in the art. Therefore, these aspects of door 2 will not be discussed further here in detail.

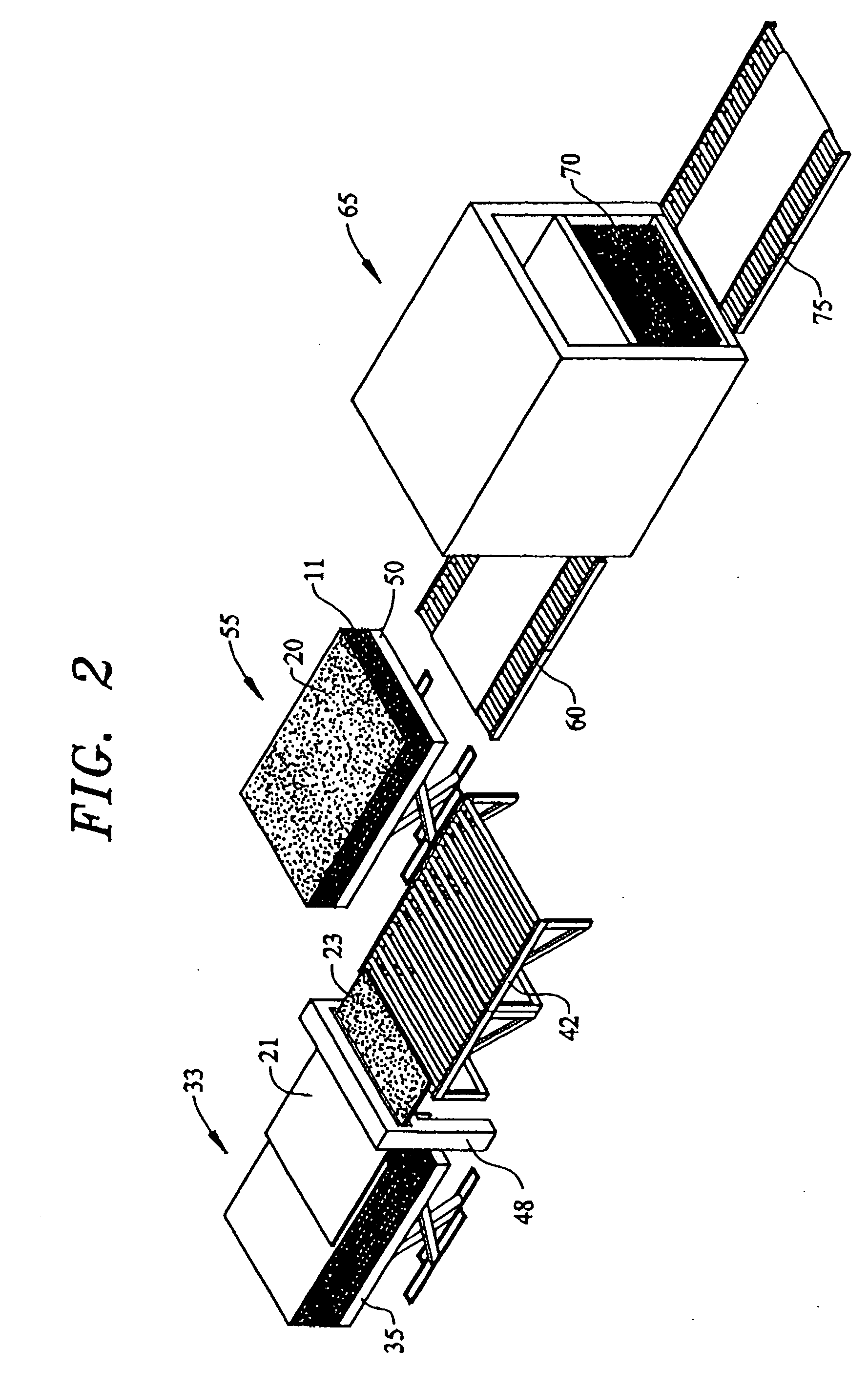

[0014] The present invention is particularly directed to the construction and method of forming core 11. In general, core 11 constitutes a laminate including a first panel 20, a second panel 21 and an intermediate fibrous binder layer 23. In accordance with the most preferred form of the invention, each of first and second panels 20 and 21 is formed from an organic material, specifically flax. On the other hand, intermediate binde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com