Method and apparatus for predicting failure in a system

- Summary

- Abstract

- Description

- Claims

- Application Information

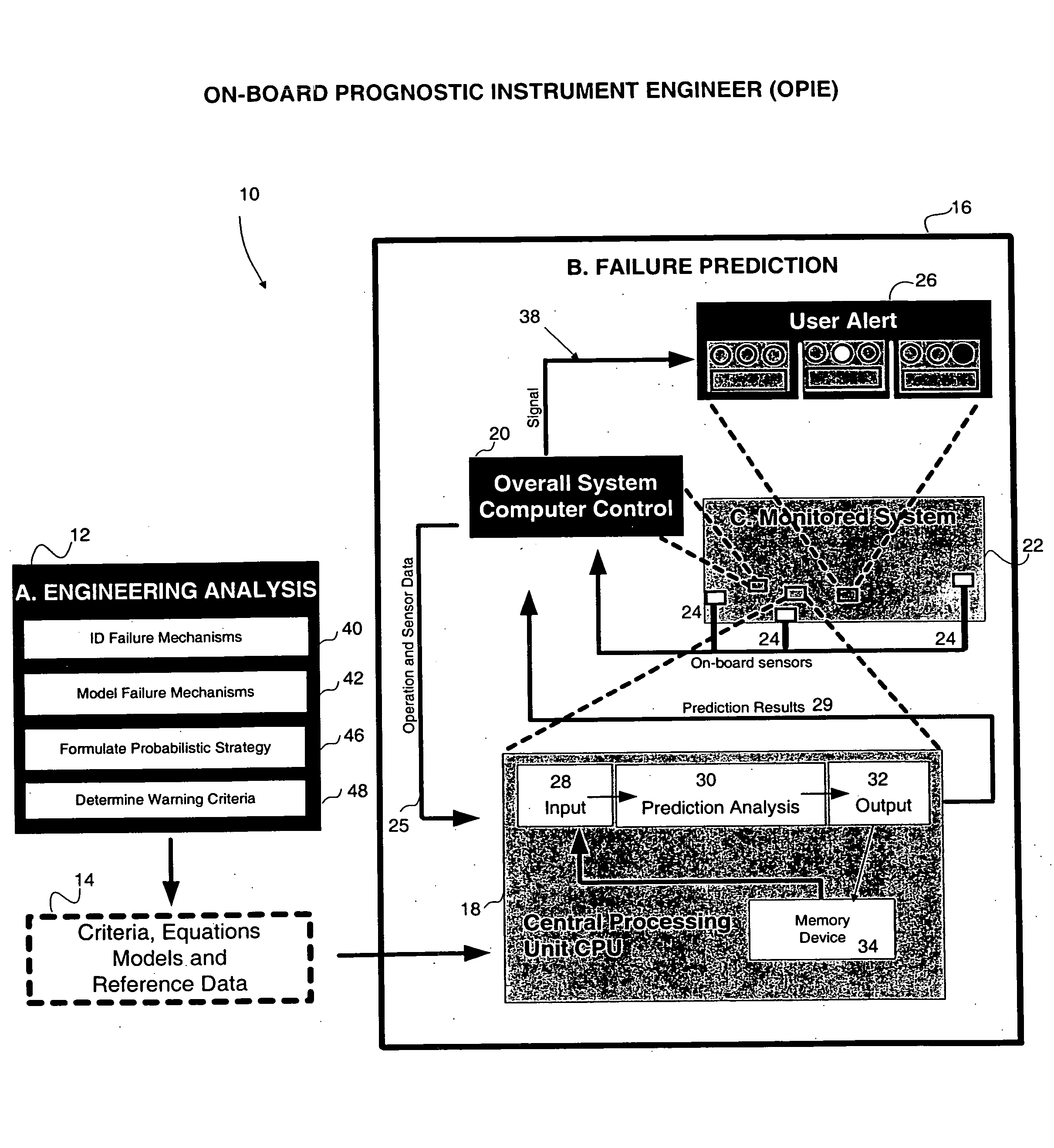

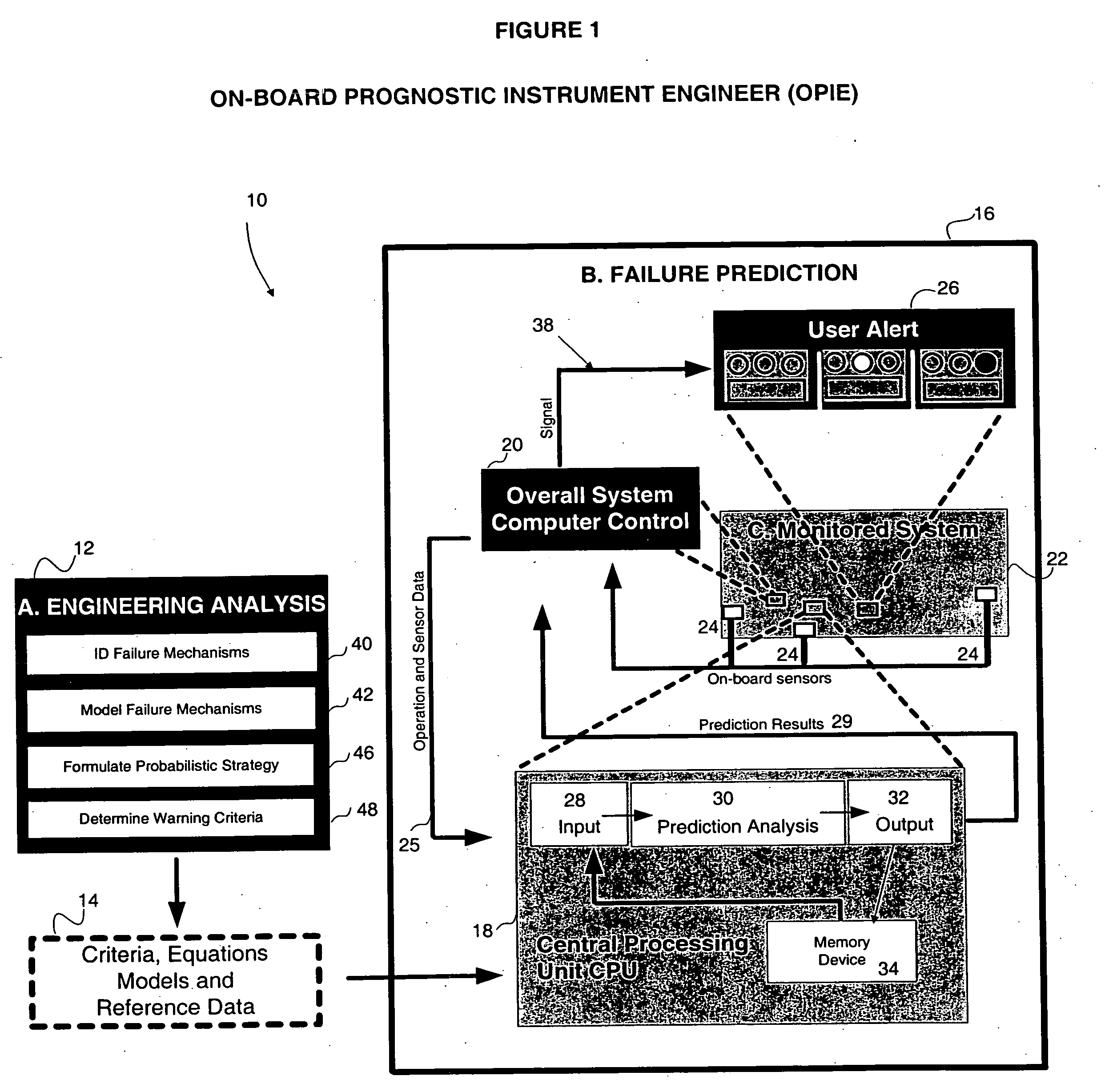

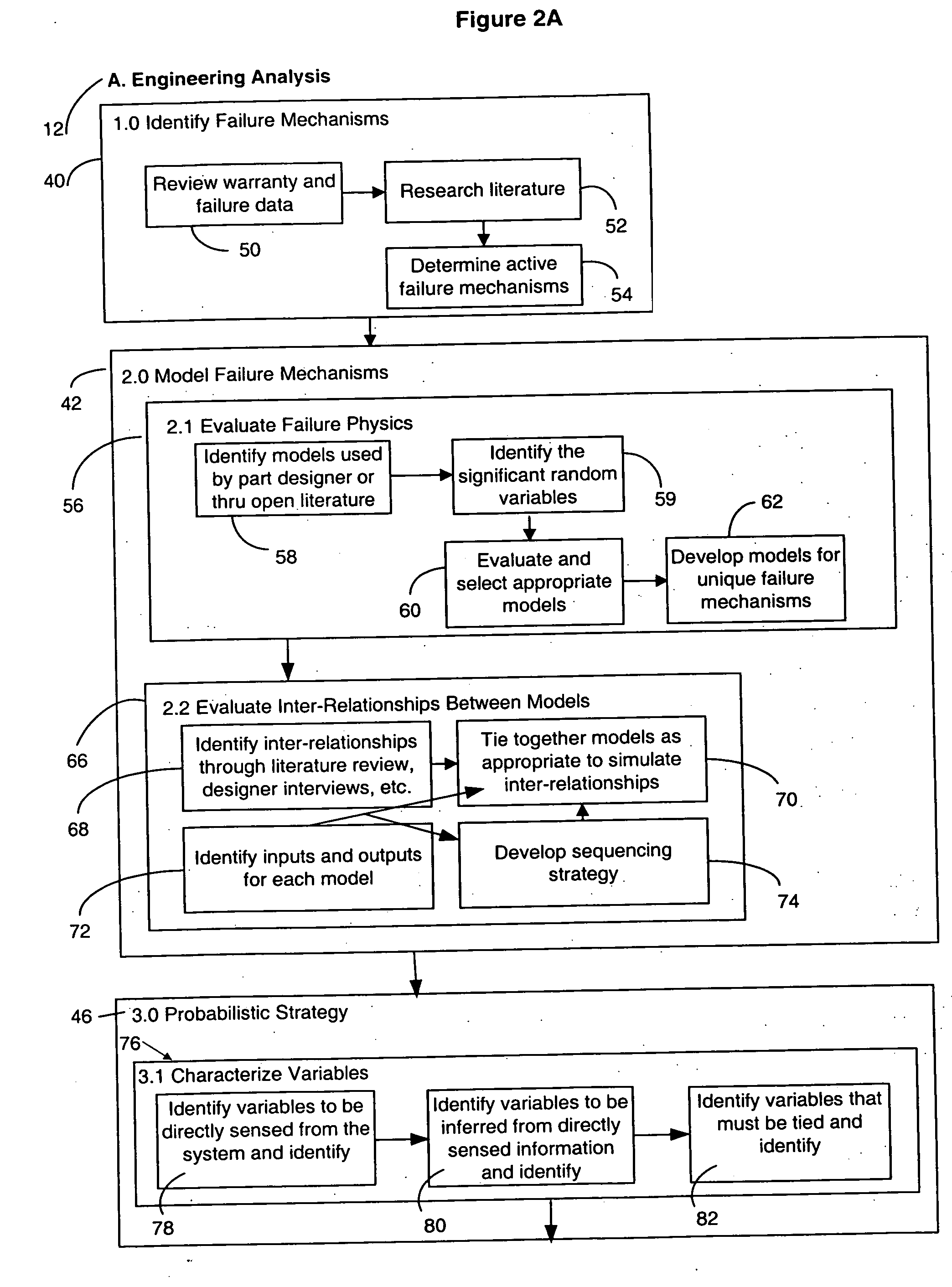

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0063] The following example describes the modeling and prediction of failure in an exemplary embodiment according to the present invention.

[0064] FIGS. 5(a)-5(f) illustrate a preferred embodiment of the invention applied to a single dynamic component, namely a composite helicopter rotor hub. Reference numerals refer to the elements as they were discussed with respect to FIGS. 1-4. In this example engineering analysis step 12 first incorporates a probabilistic approach using response surface FPM 88 techniques. Thereafter, the same example is used to demonstrate any difference that response surface ST 90, direct FPM 92, or direct ST 94 would have yielded.

[0065] A helicopter rotor hub is a structure to which the blades of the helicopter are attached. The rotor hub is a composite laminate structure, which means that it is manufactured by laying plies of composite sheets together and joining them (with an adhesive resin) to form an integral structure. Each composite sheet is called a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com