Flat strap structure

a flat strap and strap technology, applied in the field of flat straps, can solve the problems of limited application of strap products, lack of electric signal transmission function, insufficient shear strength, etc., and achieve the effect of excellent strength, enhanced shear strength and tension strength of flat straps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

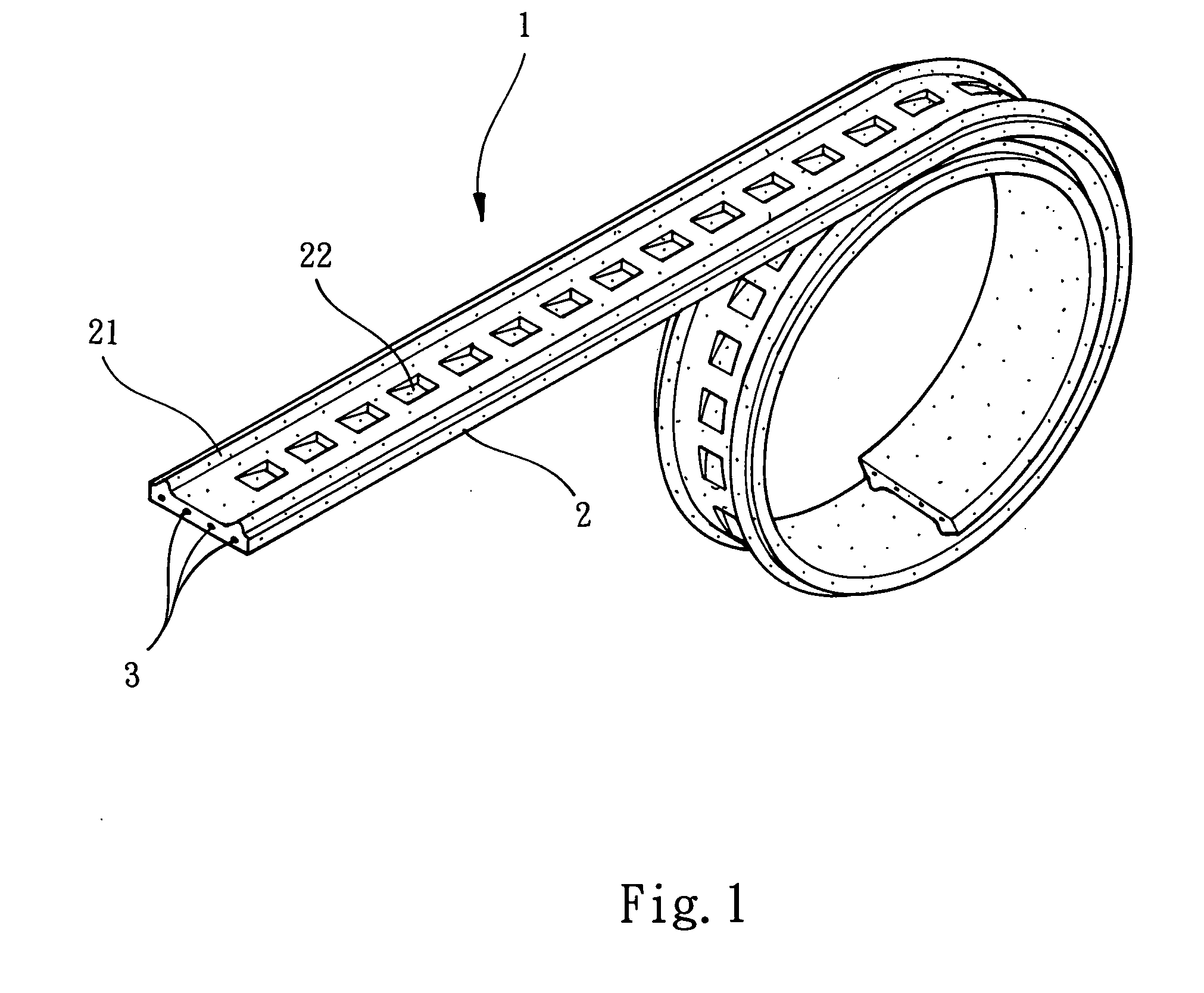

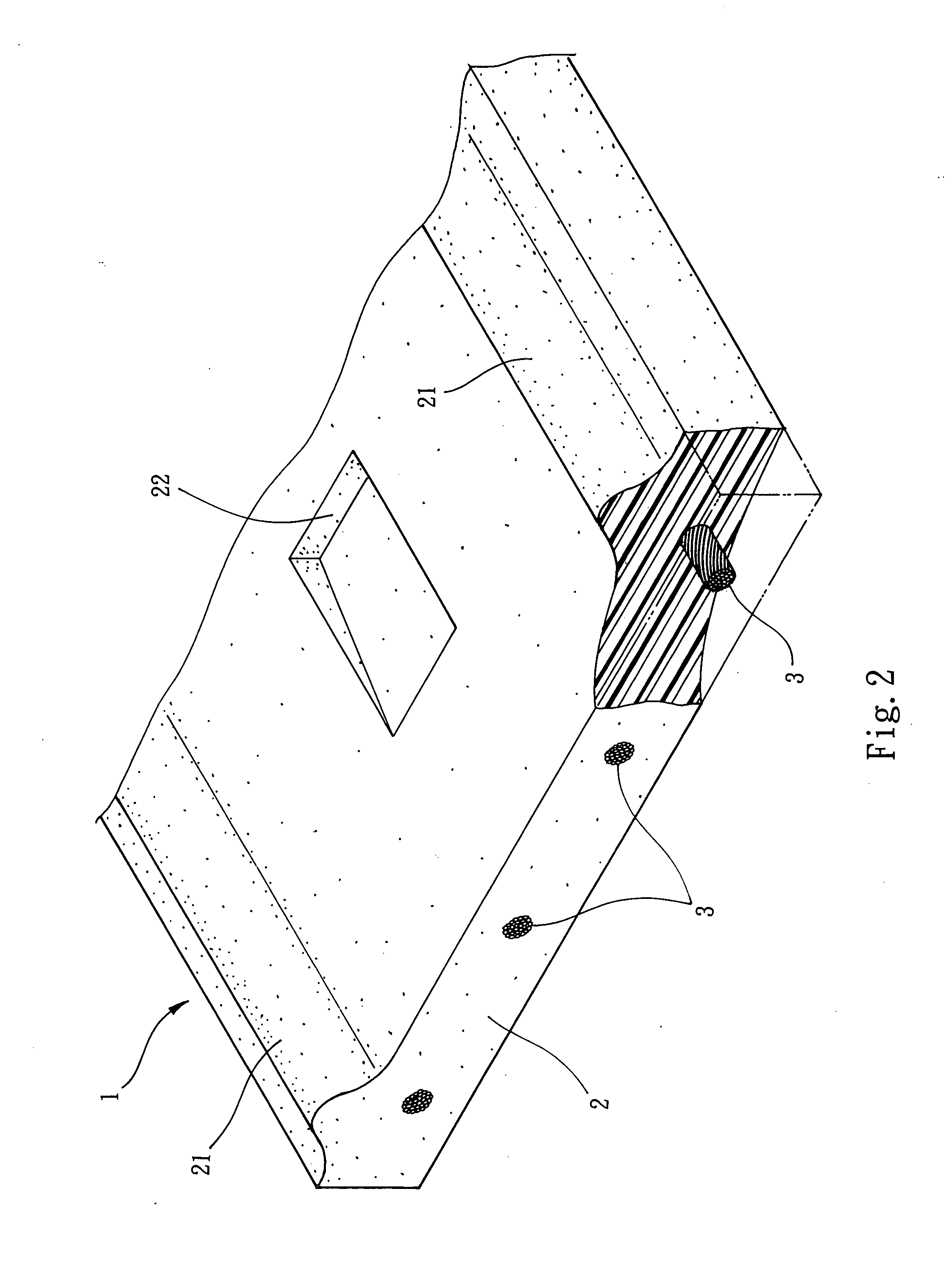

[0012] Please refer to FIGS. 1 to 5. The flat strap structure of the present invention is composed of at least one metal reinforcing wire 3 and a strap 2 made of plastic material by molding. The metal reinforcing wire 3 is integrally longitudinally embedded in the plastic strap 2. The metal reinforcing wire 3 is formed of flexible metal wire or steel cable 31 or is composed of electrically conductive wires 33 enclosed by at least one layer of cable 32. The metal reinforcing wire 3 serves to enhance the tension strength or shear strength of the flat strap 1. In the case that the electrically conductive wires 33 enclosed by the cable 32 is embedded in the plastic strap 2, not only the flat strap 1 is reinforced, but also the flat strap 1 can conduct current to transmit electric signal. For example, an interruption-detective alarm device 5 can be mounted at two ends of the strap 1 as shown in FIG. 5. In the case that the strap 1 is cut off and an interruption takes place, the alarm dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com