Modular intramedullary nail

a module and intramedullary technology, applied in the field of modules, can solve the problems of insufficient telescopic attachment, large number of nails and instruments, and difficulty for surgeons and nurses to master a great, and achieve the effect of improving vascularization and biomechanical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

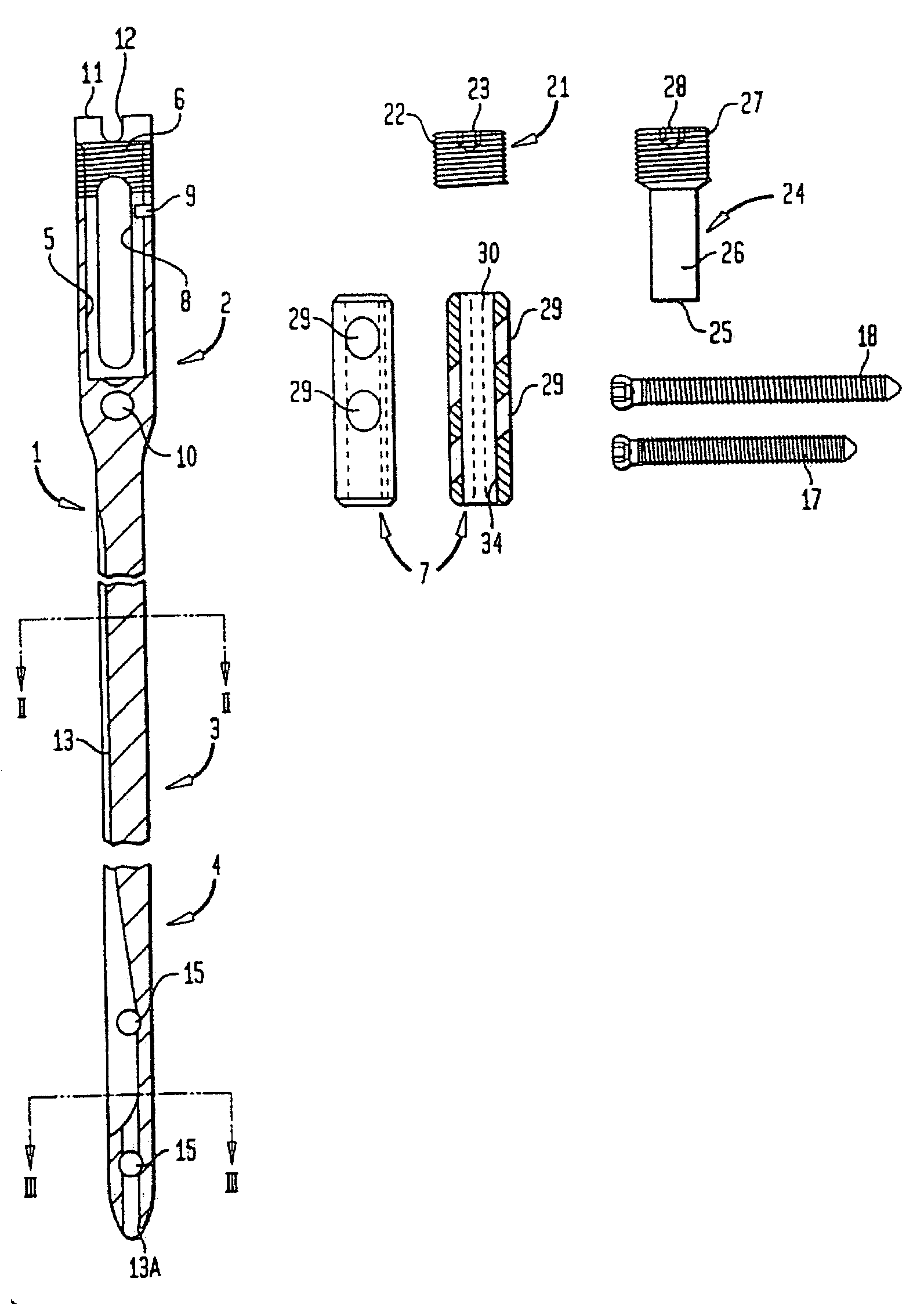

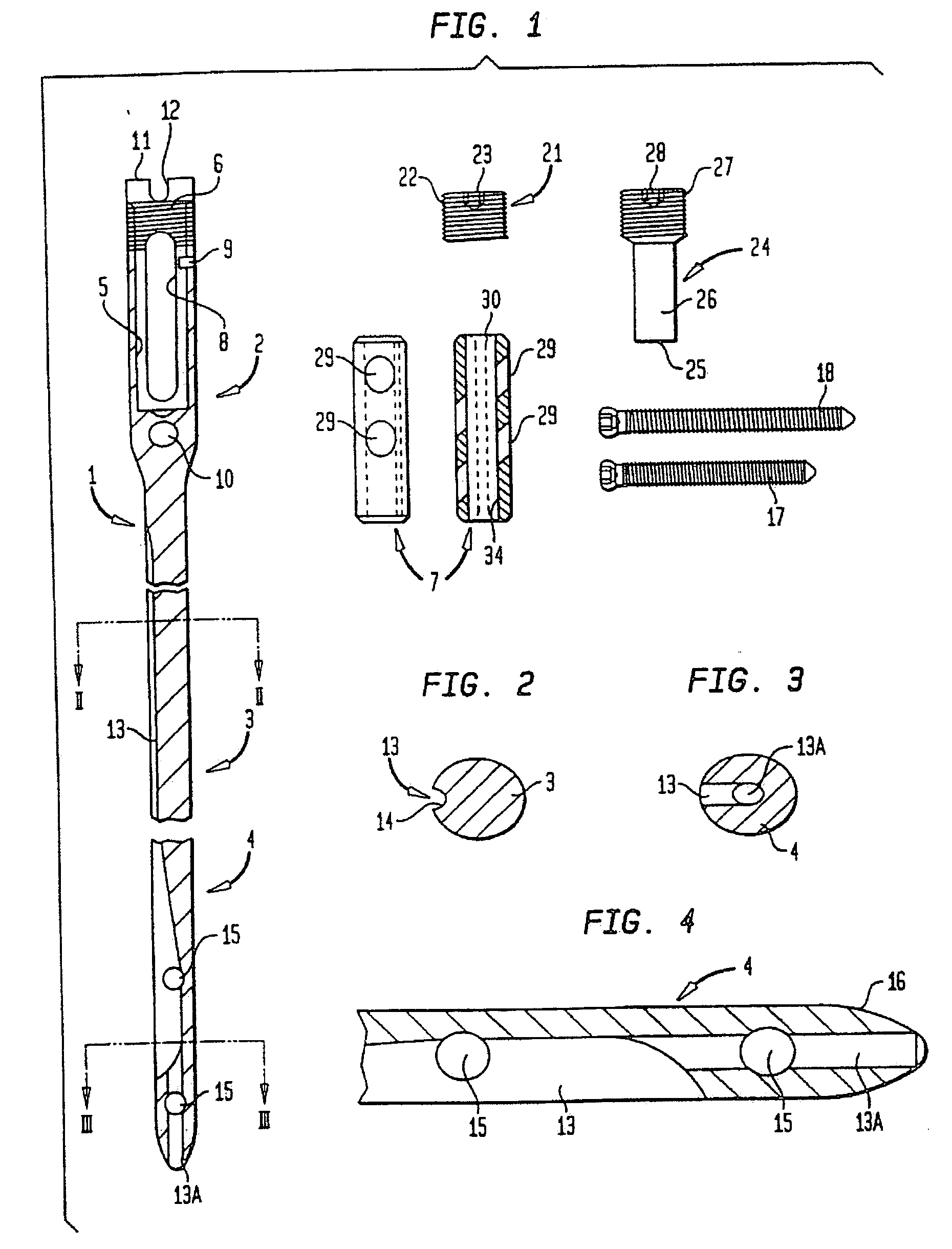

Method used

Image

Examples

fourth embodiment

[0032]FIG. 7 shows the retrograde respectively antegrade fixation of a fracture by means of an insert 31 for a intramedullary nail comprising a single guiding bore 29 but which is otherwise identical to insert 7. In this FIG. 7 as well as in FIG. 8, it is visible how guiding pin 9 engages in guiding groove 30 of the insert and thus precisely aligns the insert with respect to longitudinal slot 5. It further appears that, an insertion of the sleeve with one of its ends 32 facing in the distal direction or with the other end 33 facing in the distal direction allows either a retrograde or an antegrade fixation. In this case, as in the case according to FIG. 8 the cap screw 21 serves to fasten the insert by a clamping action and furthermore as a protection against an accretion of tissue into the threaded portion.

fifth embodiment

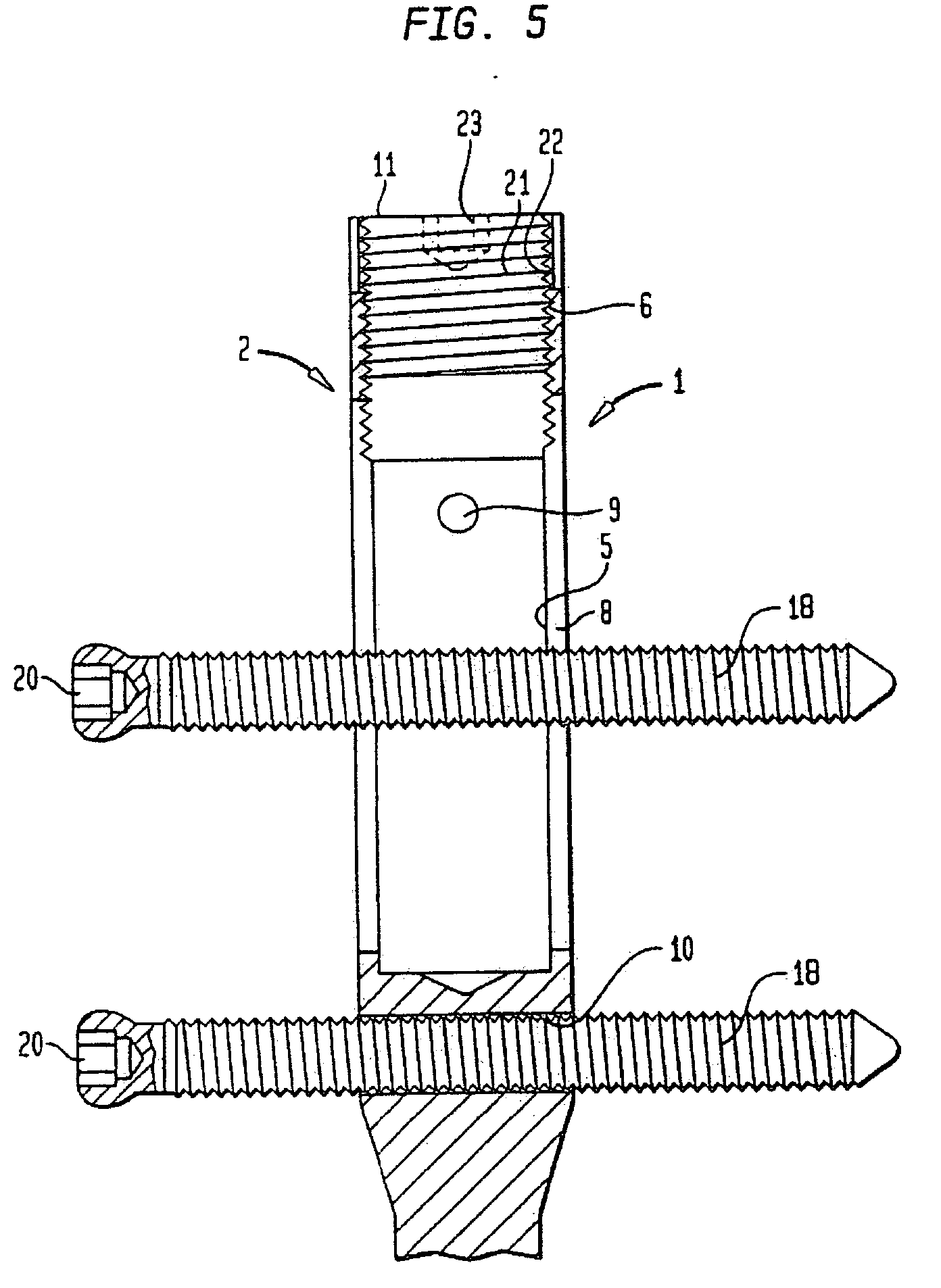

[0033]FIG. 8 shows the use of insert 7 for a intramedullary nail with two guiding bores 29 in the case of a retrograde respectively an antegrade fixation of the fracture. The considerations with regard to insert 31 according to FIG. 7 apply in an analogous manner.

sixth embodiment

[0034]FIG. 9 shows a intramedullary nail for treating fractures in the central area of the shaft according to the invention. The nail is cannulated and comprises a throughgoing slot 45 which extends in parallel to the longitudinal axis. Underneath longitudinal bore 5, which extends beyond the longitudinal extension of slot 8 in the distal direction, the proximal portion does not contain a transversal bore at its distal end. Insert 7 comprises at least one guiding bore 29. In the embodiment shown insert 7 comprises two guiding bores 29 which are oriented transversal to the longitudinal axis 46 of insert 7 respectively proximal portion 2. Fixing screws 18 are received within said guiding bores 29 whereby another screw is provided in the distal portion 4 to stabilise a fracture of the central area of the shaft.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com