One-piece molded corner flashing for dormers, roof offsets and chimneys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

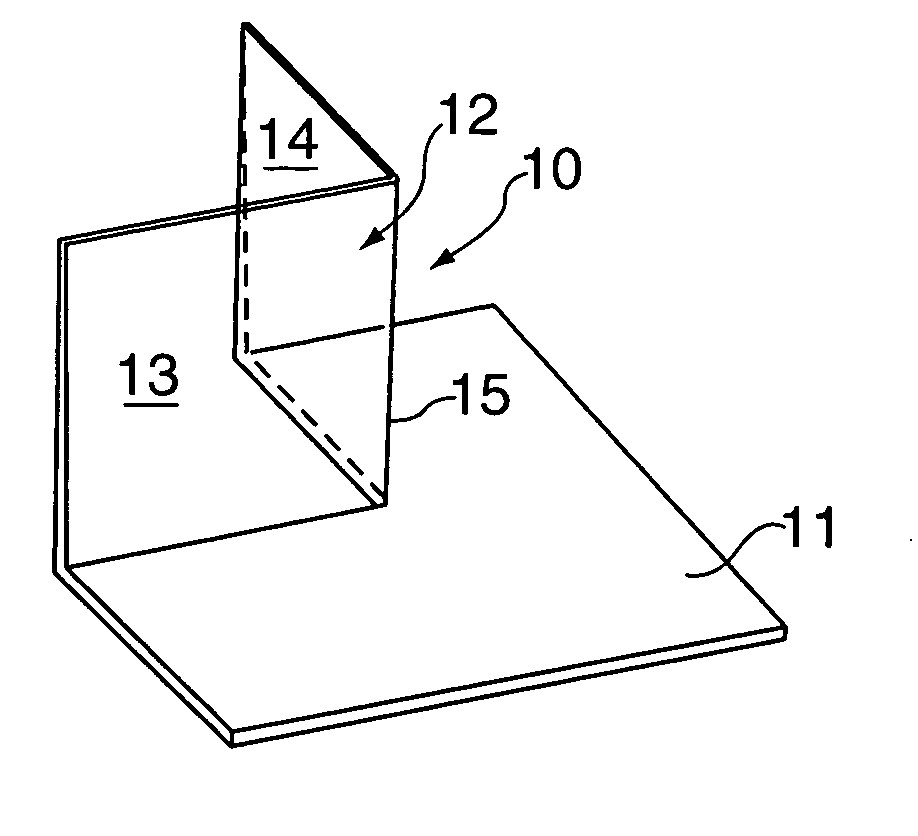

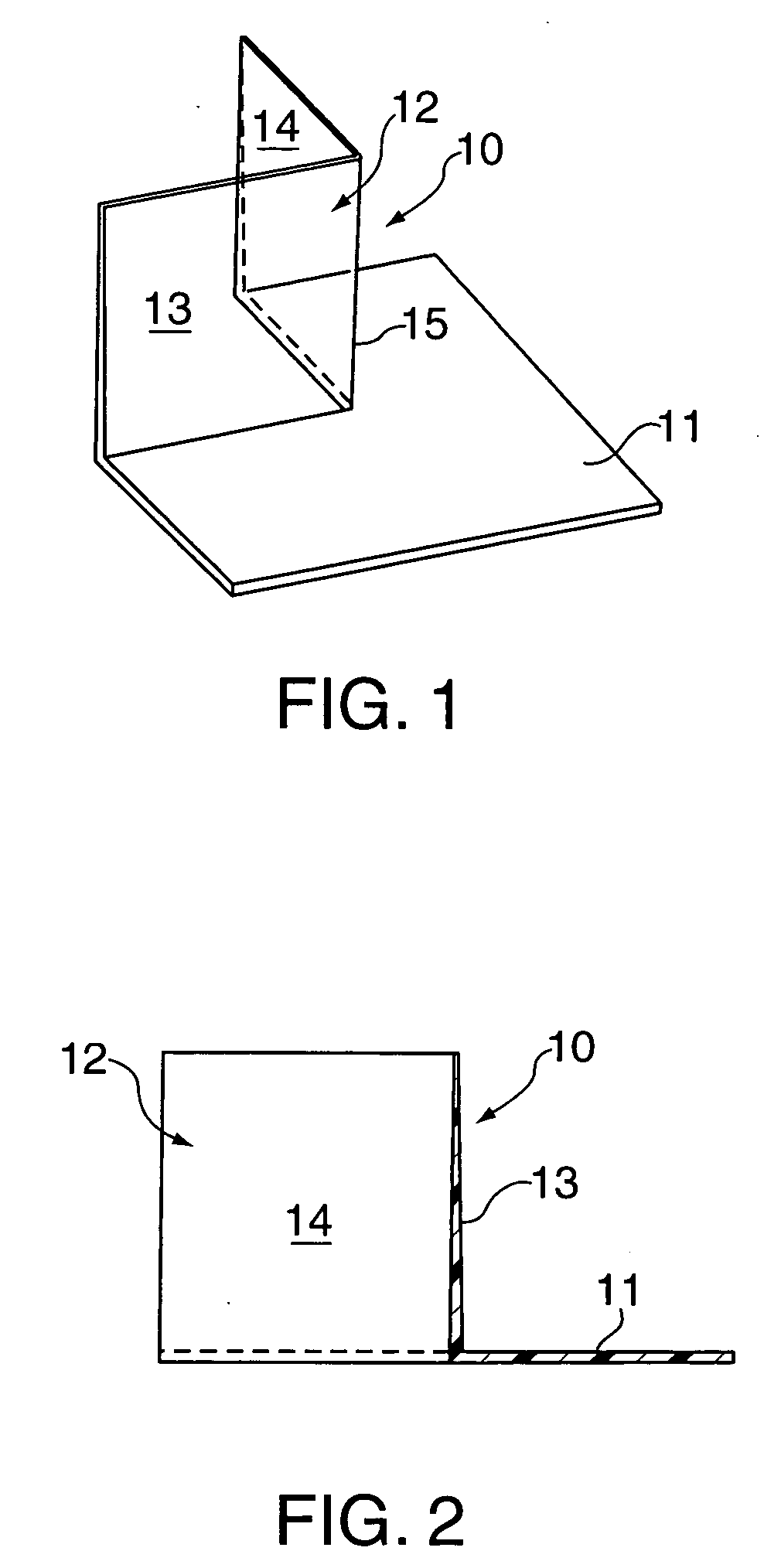

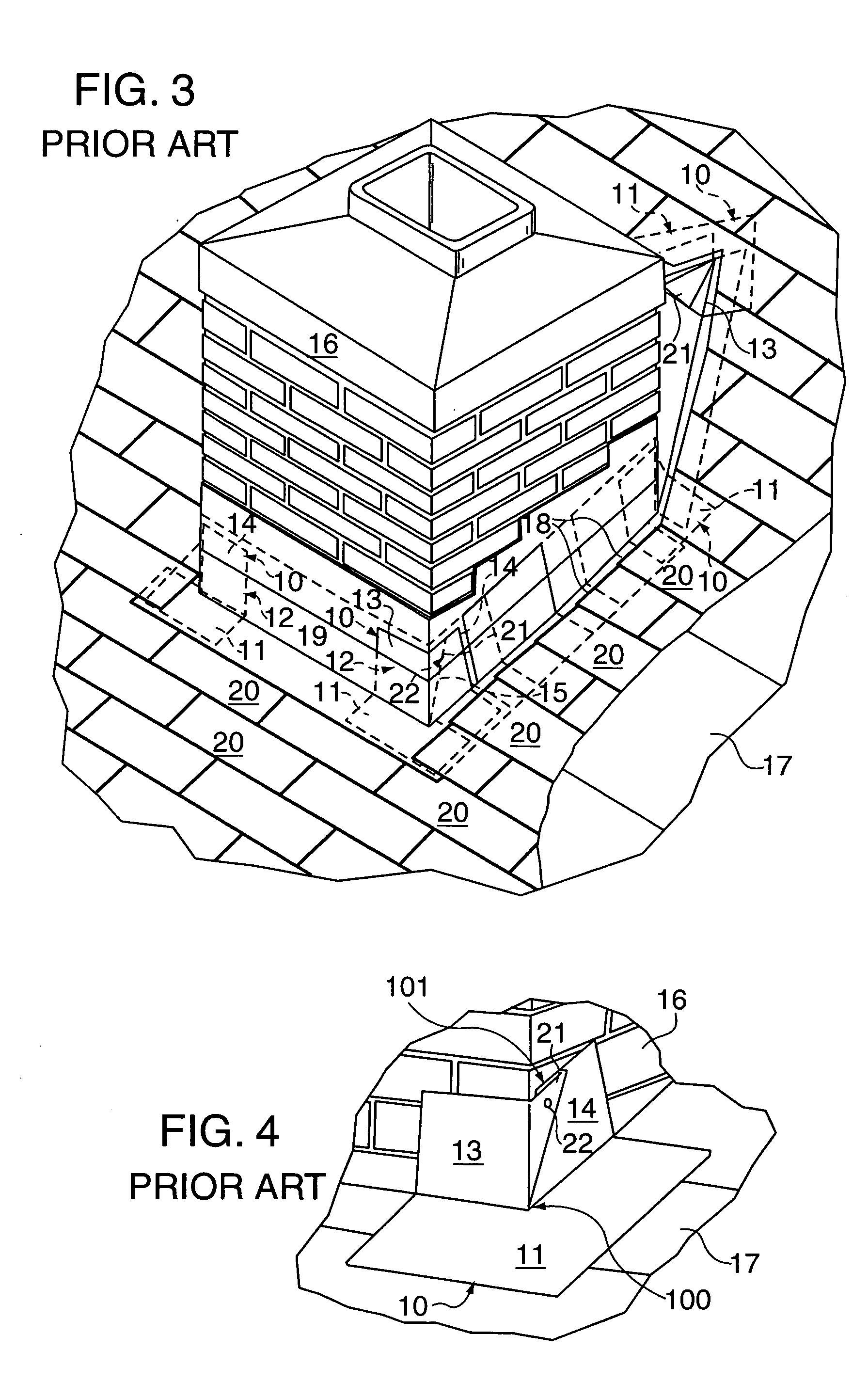

[0015] In the prior art drawings of FIGS. 1-4, the McGady corner flashing 10 includes a base 11 with an integral upstanding corner 12 having a pair of sides 13 and 14 in right-angled relation. With the sides integrally joined at a corner 15, the upstanding corner 12 is substantially in right angle relationship with the base 11.

[0016] As U.S. Pat. No. 5,077,943 describes, the base 11 is rectangular with parallel top and bottom edges, and parallel opposite sides intersecting at corners. The upper left-hand corner of the base 11 is notched out to provide a rectangular recess with edges which intersect at a corner spaced from the top, bottom and side edges of the base. The upstanding corner 12 forms a continuous junction with the base member that is coextensive with the recess, and the base 11 is “L”-shaped with leg portions radiating from sides 13 and 14 of the upstanding corner 12. Composed of a bendable plastic material, the flashing 10 is selected of a thickness so as to be suffici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com