Prefabricated stand for hydronic systems

a technology for hydronic systems and stands, applied in the direction of fluid heaters, heating types, lighting and heating apparatus, etc., can solve the problems of high installation cost of hydronic systems, time and effort required, complex and expensive,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

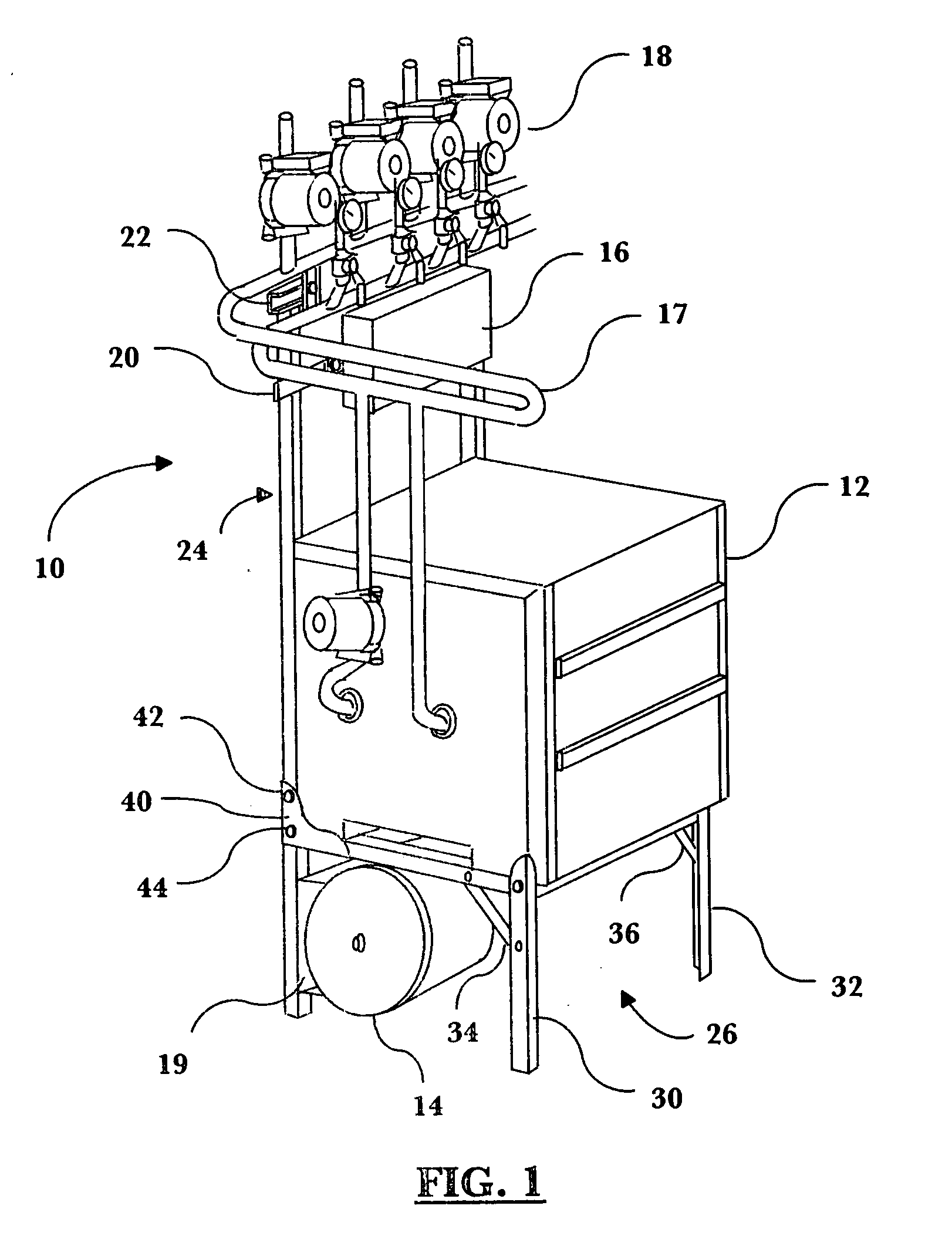

[0015]FIG. 1 illustrates a stand assembly 10 incorporating the principles of the present invention. The stand assembly 10 supports a variety of hydronic system components, including a boiler 12, an expansion tank 14, an electronic control panel 16, a primary loop module 17, and a zone manifold module 18. The expansion tank 14 is secured to the stand assembly 10 via a tank mounting bracket 19. The electronic control panel 16 is secured to the stand assembly 10 via an electronics mounting bracket 20. The zone manifold module 18 can secured to the stand assembly 10 via a conventional manifold mounting mechanism such as a uni-strut 22, or as described with reference to a specific zone manifold module.

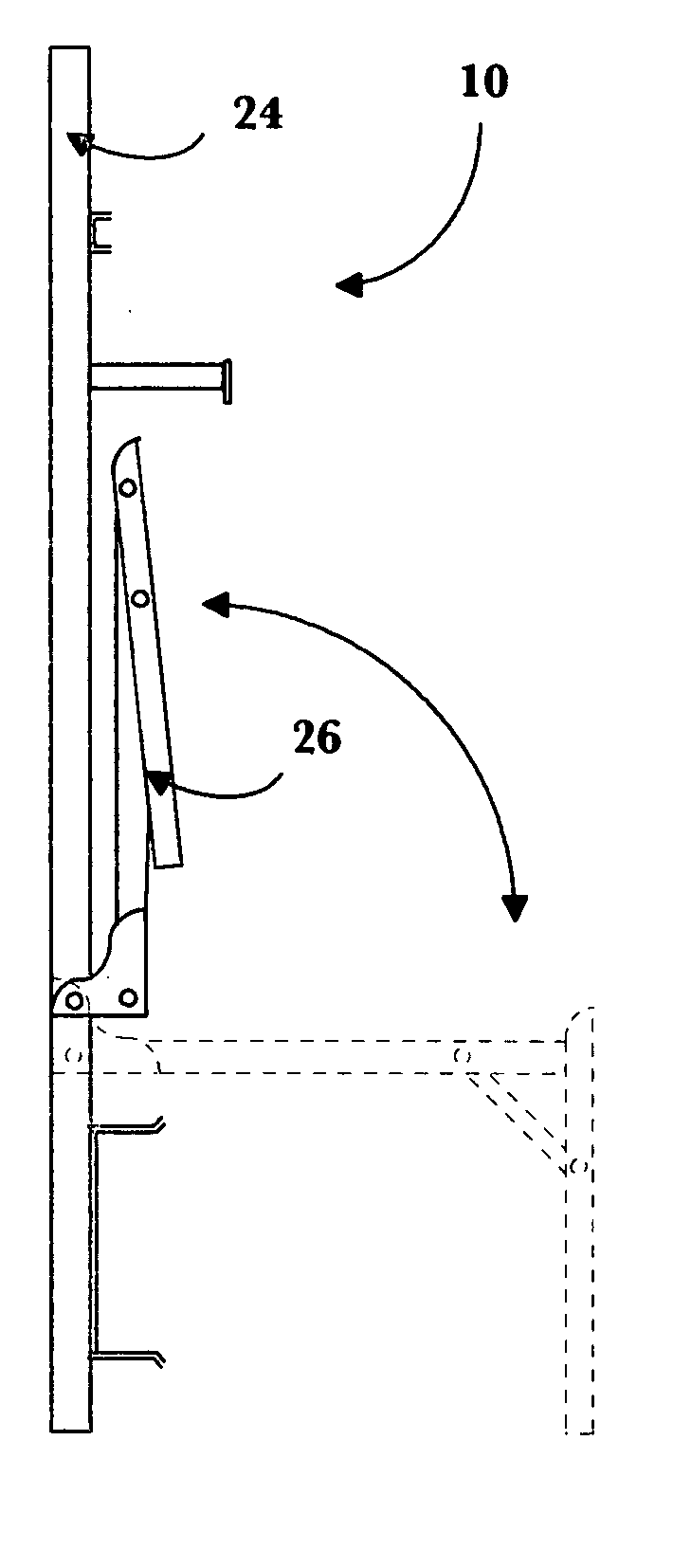

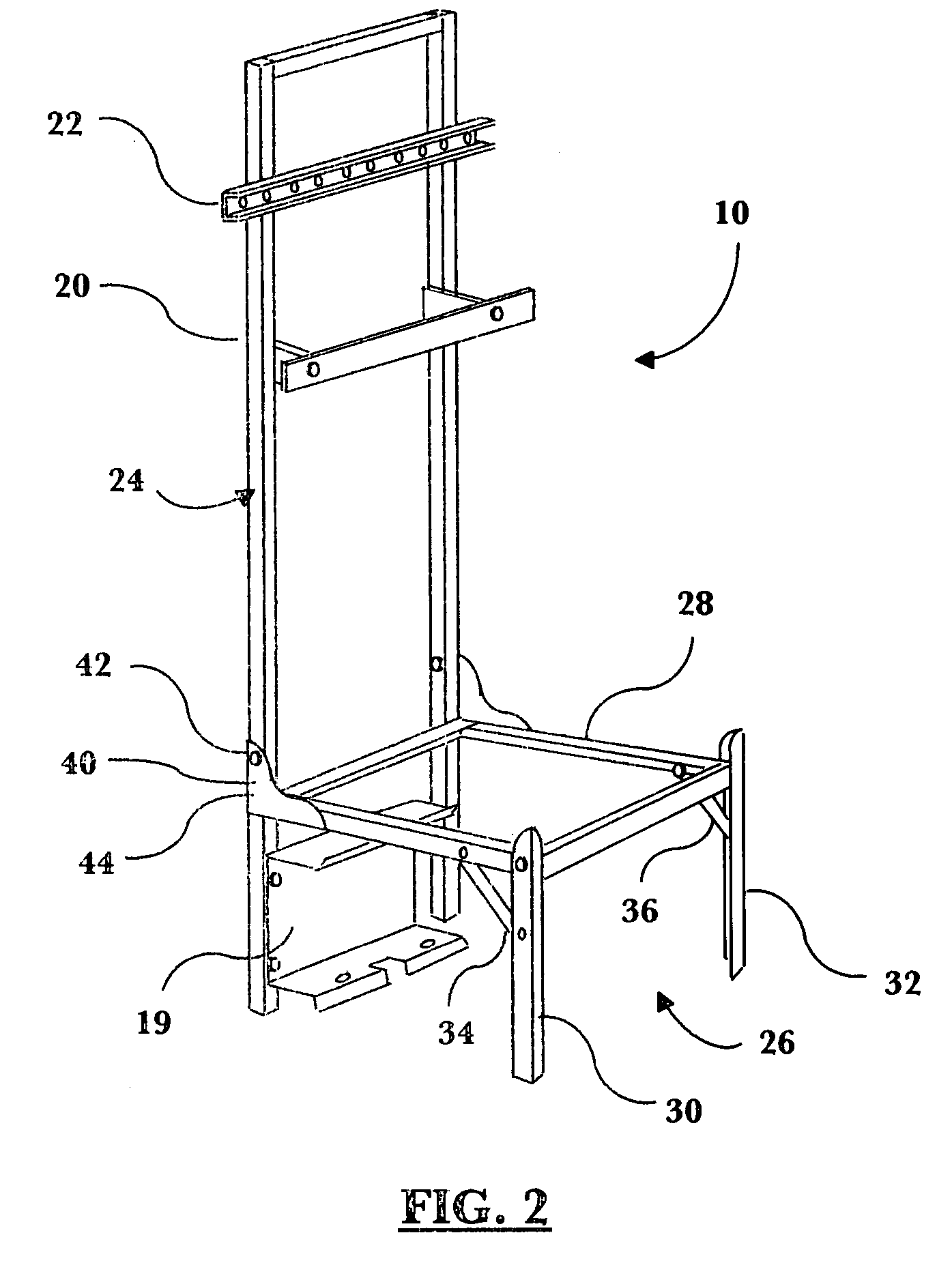

[0016] Details of the stand assembly 10 are shown in FIGS. 2 through 4. The stand assembly 10 includes a fixed back portion 24. A selectively movable platform portion 26 is connected to the back portion 24.

[0017] The platform portion 26 includes a platform 28 adapted and constructed to su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com