Composition for release layer of in-mold decoration

a technology of in-mold decoration and release layer, which is applied in the direction of transportation and packaging, synthetic resin layered products, coatings, etc., can solve the problems of reducing the efficiency of the photoinitator in the composition, bringing many tradeoffs, etc., and achieves room-light handling, improved release characteristics, and improved shelf life stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

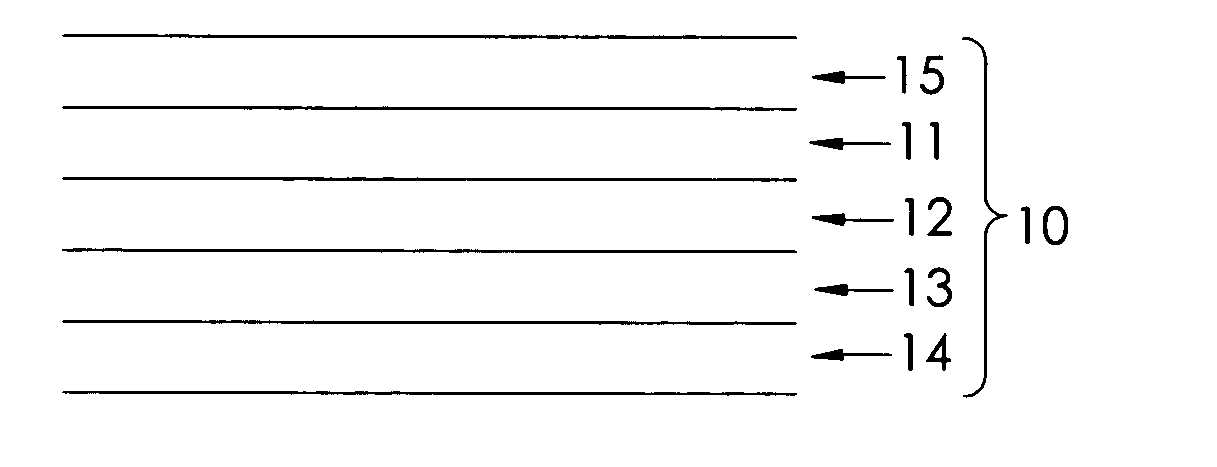

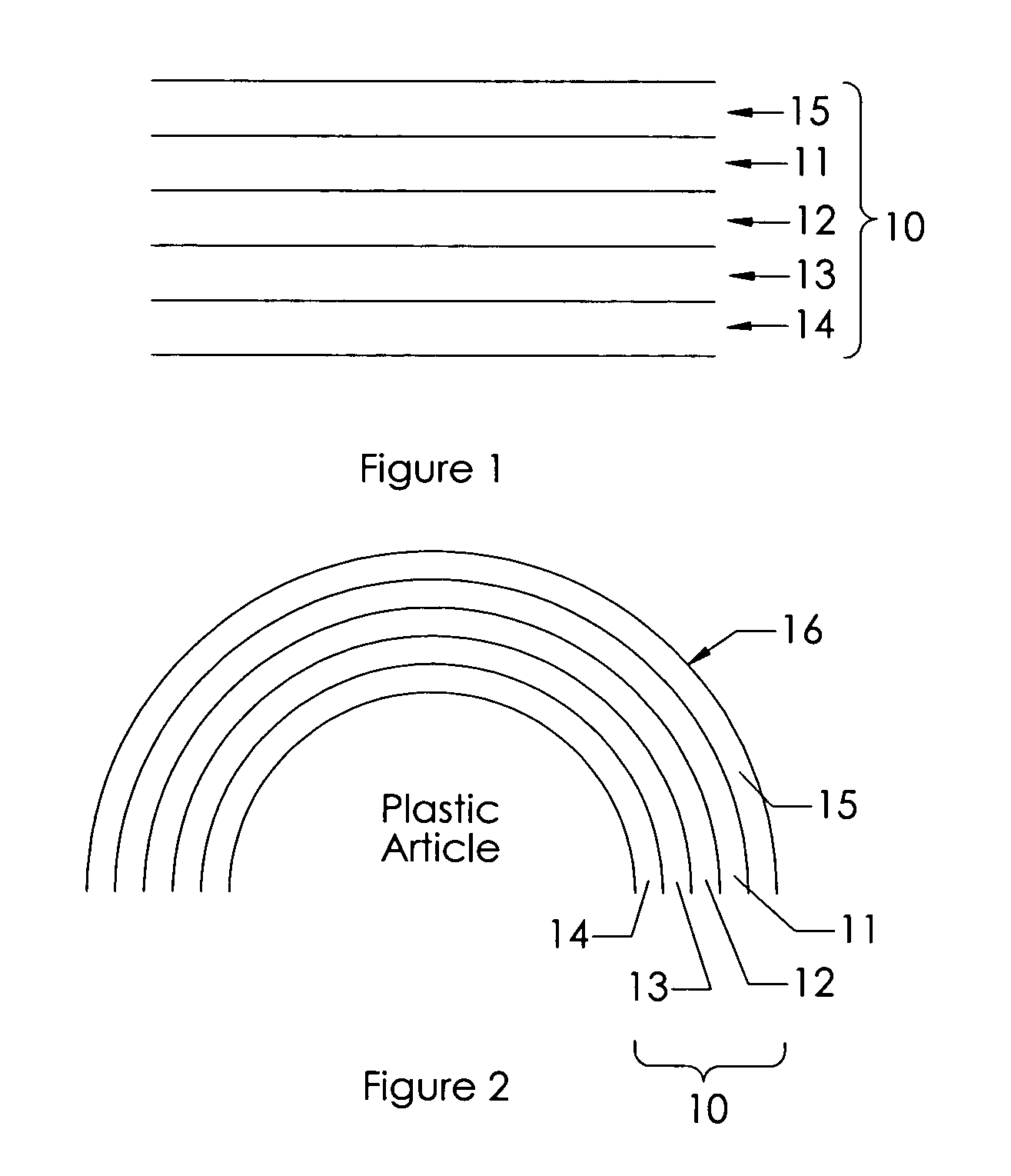

Image

Examples

example 1

UV Screening Efficiency

A. Formation of Film Comprising a Release Layer of the Present Invention

[0059] 1.53 Grams of Durite SD-1708 (phenolic resin, Bordon Chemical, Inc.) was dissolved in 7.2 gm of MEK. 1.3 Grams of CYMEL 303ULF (methylated melamine resin, Cytec Industries Inc), 0.03 gm of CYCAT 600 (DDBSA, dodecylbenzene sulfonic acid, a crosslinking catalyst, Cytec Industries Inc.), 0.07 gm of DMS S12 (silanol terminated polydimethylsiloxane, Gelest Inc.) and 1.4 gm of CAB 553-04 (10% in MEK) (cellulose acetate butyrate, Eastman Chemical Co.) were then added and mixed with a Vortexer. The release layer composition formed was coated on a PET film (1.42 mil, PT1 from Mitsubishi, Interfilm Holding, Inc., Easley S.C.) with a #6.5 Meyer bar with a target thickness of about 2 um. The coated film was dried at 70° C. for 5 minutes and cured at 120° C. for 10 minutes.

[0060] The resultant film was then exposed to UV (Fusion V, H lamp at dosage of 4.2 J / cm2) using a conveyor curing syste...

example 2

Thermal Sensitive Release & Edge Sharpness Improvement

[0065] The composition of the release layer of Example 1A was used in this example. A durable layer was prepared by pre-reaction of 6.84 gm (15% in MEK) of CAP-504-0.2 (cellulose acetate propionate, from Eastman Chemical Co.) and 1.89 gm CaCO3 (27.5% in MEK, containing 6.27% CAP-504-0.2) with 2.53 gm (15% in MEK) of Desmodur N3300A (polyisocyanate, Bayer Polymers) and 0.1% DBTDL at 50° C. for 18 minutes. After pre-reaction, the following ingredients were then added into the pre-reacted CAP solution: 2.94 gm (50% in MEK) of Ebecryl 1290 (aliphatic polyurethane acrylate, UCB Chemicals), 0.1 gm of MEK-ST (30% in MEK, a silica dispersion from Nissan Chemicals), 0.40 gm of (25% in MEK) 1:1 w % ratio of triethanolamine and poly-Q (aminated tetrol from Arch Chemicals, Norwalk, Conn.) and 0.43 gm of a photoinitiator (PI) solution containing 1.5% of BMS (4-(p-tolylthio)benzophenone, Aldrich, Milwaukee, Wis.), 0.8% of Irgacure 651 (2,2-di...

example 3

Less Yellowness

[0067] The same compositions of Example 1A were used except that, in the release layer, 1.53 gm of Resicure 5200 (meta-Novolac resin, Shenectady International Inc.) was used to replace Durite SD-1708, 0.12 gm of CYCAT600 was used to replace 0.03 gm of CYCAT and 3.06 gm of CAB 553-04 (10% in MEK) was used to replace 1.4 gm of CAB 553-04. The same degree of UV screening was observed with little yellowing in the visible region.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com