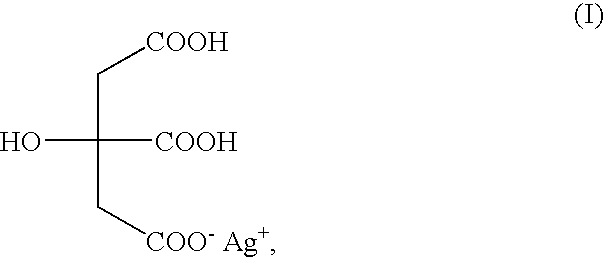

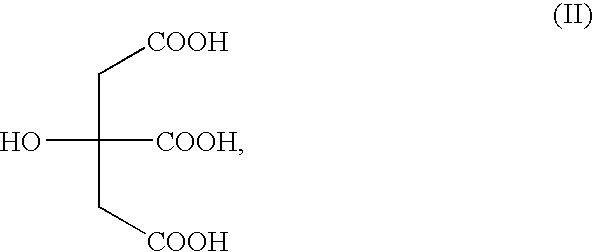

Anhydrous silver dihydrogen citrate compositions

a technology of silver dihydrogen citrate and composition, applied in the field of antimicrobial compositions, can solve the problems of unstable silver dihydrogen citrate used in the proposed methods, inconvenient use, and dusting agent drying,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Preparation of Stock Silver Dihydrogen Citrate Solution

[0037] Water was introduced into a reverse osmosis unit, passing through a semi-permeable membrane to remove impurities and producing deionized water. Anhydrous 99% pure citric acid was mixed with the water to produce 200 gallons of a 20% (wt / vol) (796 g citric acid per gallon water) solution. The 200 gallons of 20% citric acid were directed into an ion chamber containing having positive and negative electrodes, each consisting of 200 troy ounces of 999 fine silver. The positive and negative electrodes were spaced at least 2.0 mm apart, allowing the citric acid solution to pass between the two electrodes. An ion generation controller (IGC) power supply including a positive and a negative conductor was attached to the positive and negative electrodes. The IGC applied a current of 5 amps at 17 volts, pulsed every 9 seconds, with a polarity change at 1 minute intervals. Throughout the process, the electrode gap was adjusted in ord...

example 2

Preparation of Anhydrous Silver Dihydrogen Citrate

[0039] A 1,000 ml sample of the stock solution, prepared as in foregoing Example 1, was obtained from SSA Batch No. 04.06.03 and was confirmed to have a concentration of ionic silver of 2400 ppm using an Orion™ 290A processor with an ion specific electrode (ISE). The processor was calibrated using Orion™ standard solutions.

[0040] The 1,000 ml stock solution was decanted into two 2.5″×8″×15″ Pyrex™ heat resistant glass trays. The liquid stock solution level was approximately 1.5″ in each tray.

[0041] The trays were then placed into a small commercial-grade freeze-drying unit, which consisted of a drying chamber with temperature control shelves, a condenser to trap water removed from the product, a cooling system to supply refrigerant to the temperature control shelves and condenser, a vacuum system to reduce the pressure in the chamber and condenser to facilitate the drying process. Cooling and vacuum pressure settings were kept wit...

example 3

Reconstitution of Silver Dihydrogen Citrate Solution

[0043] The crystalline powder from Example 2 was then reconstituted using approximately 794 ml of pharmaceutical-grade pure water in a 1,000 ml Pyrex glass flask. The solution was then agitated via magnetic stirrer for 30 minutes and put into a light-proof storage cabinet for 24 hours.

[0044] The concentration of silver ion in the reconstituted solution was then measured using the Orion 290A processor and ISE described in Example 2. Measurements were obtained at 24, 28 and 72 hours and at intervals of 1 week for a total of 4 weeks. The 24 hour reading and the week 4 readings were 2398 ppm and 2407 ppm, respectively. These concentrations are essentially the same as the 2400 ppm stock solution (within the % error operational specifications for the Orion 290A™ processor).

PUM

| Property | Measurement | Unit |

|---|---|---|

| voltage | aaaaa | aaaaa |

| peak voltage | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com