Bending device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

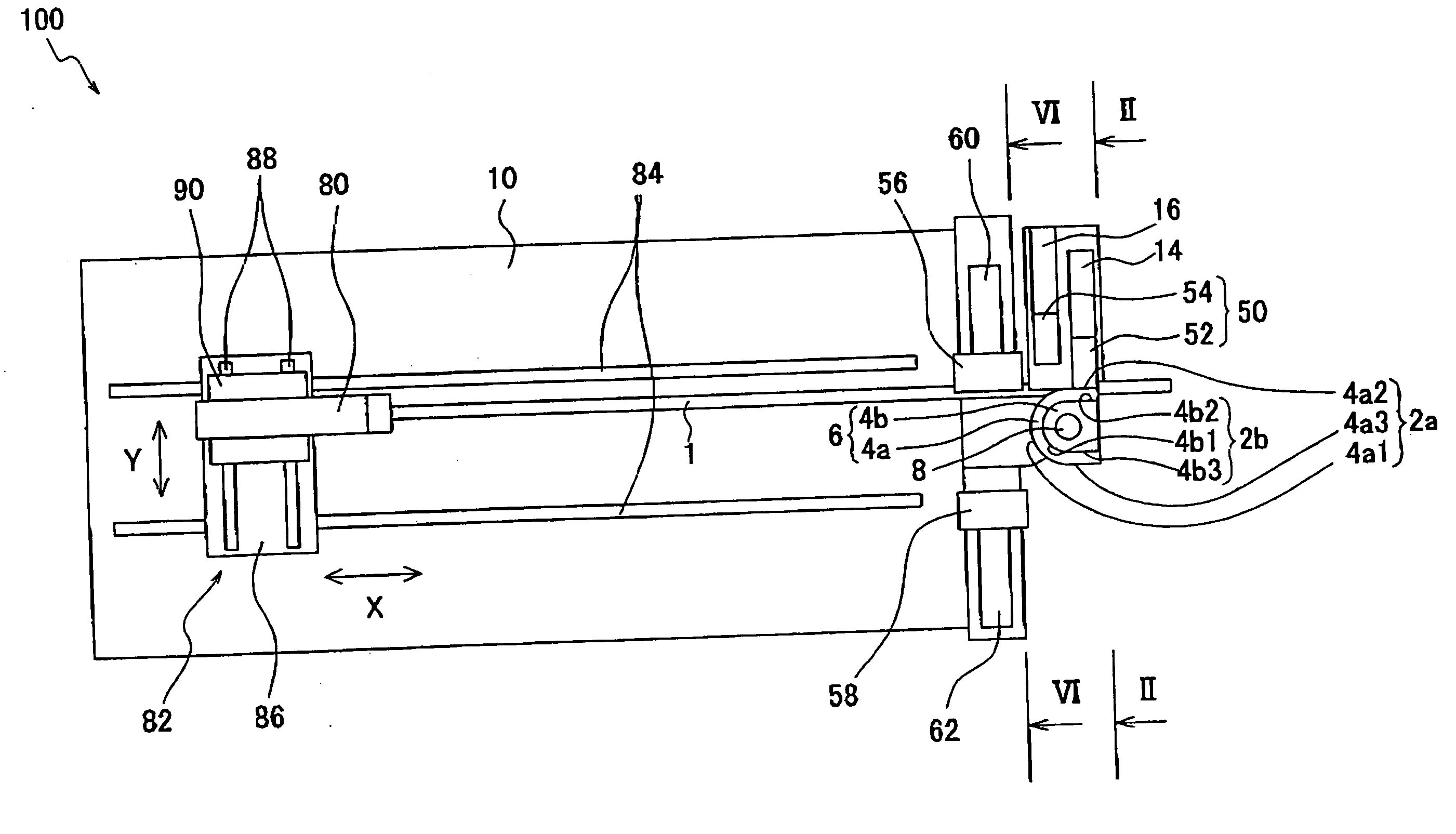

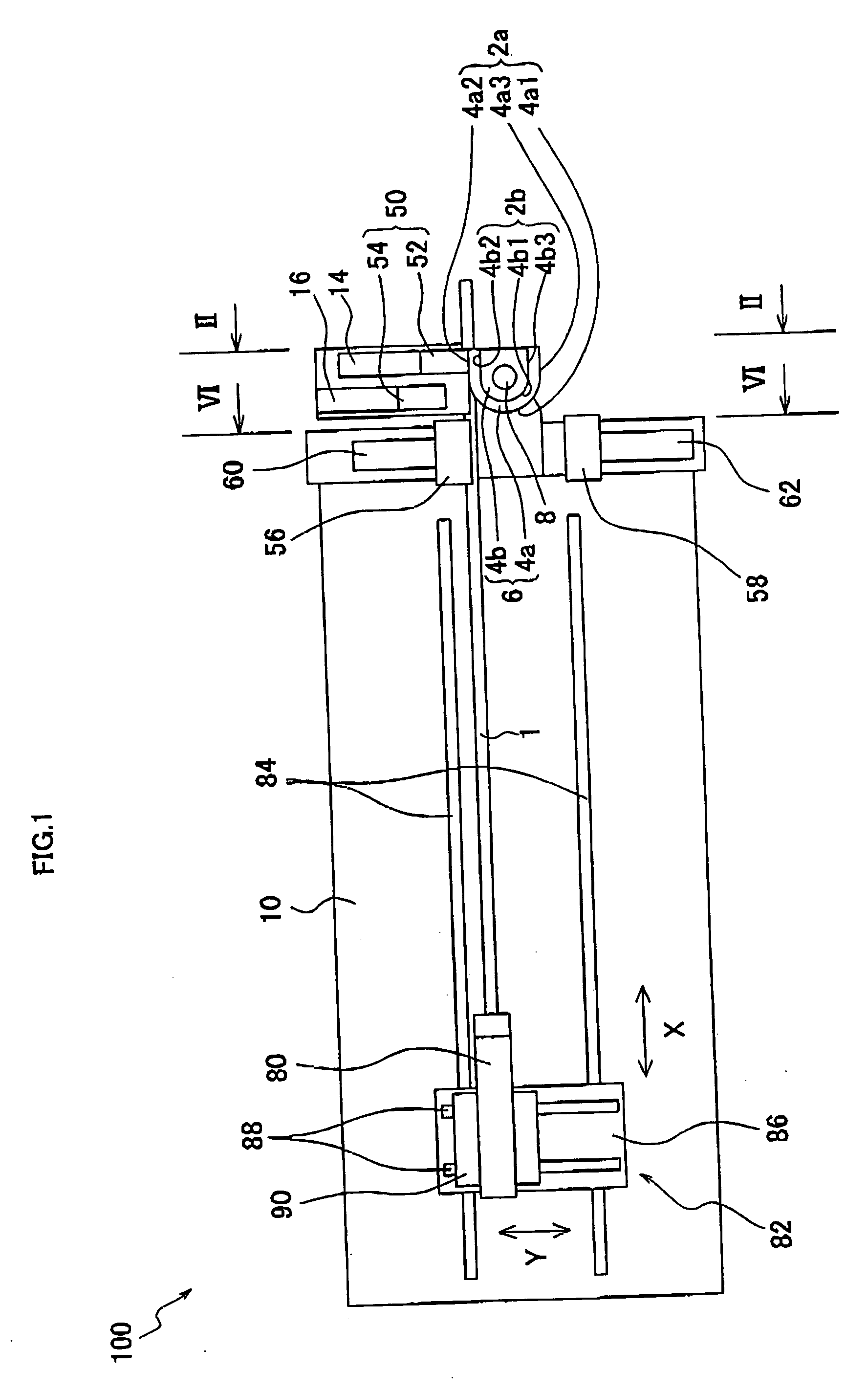

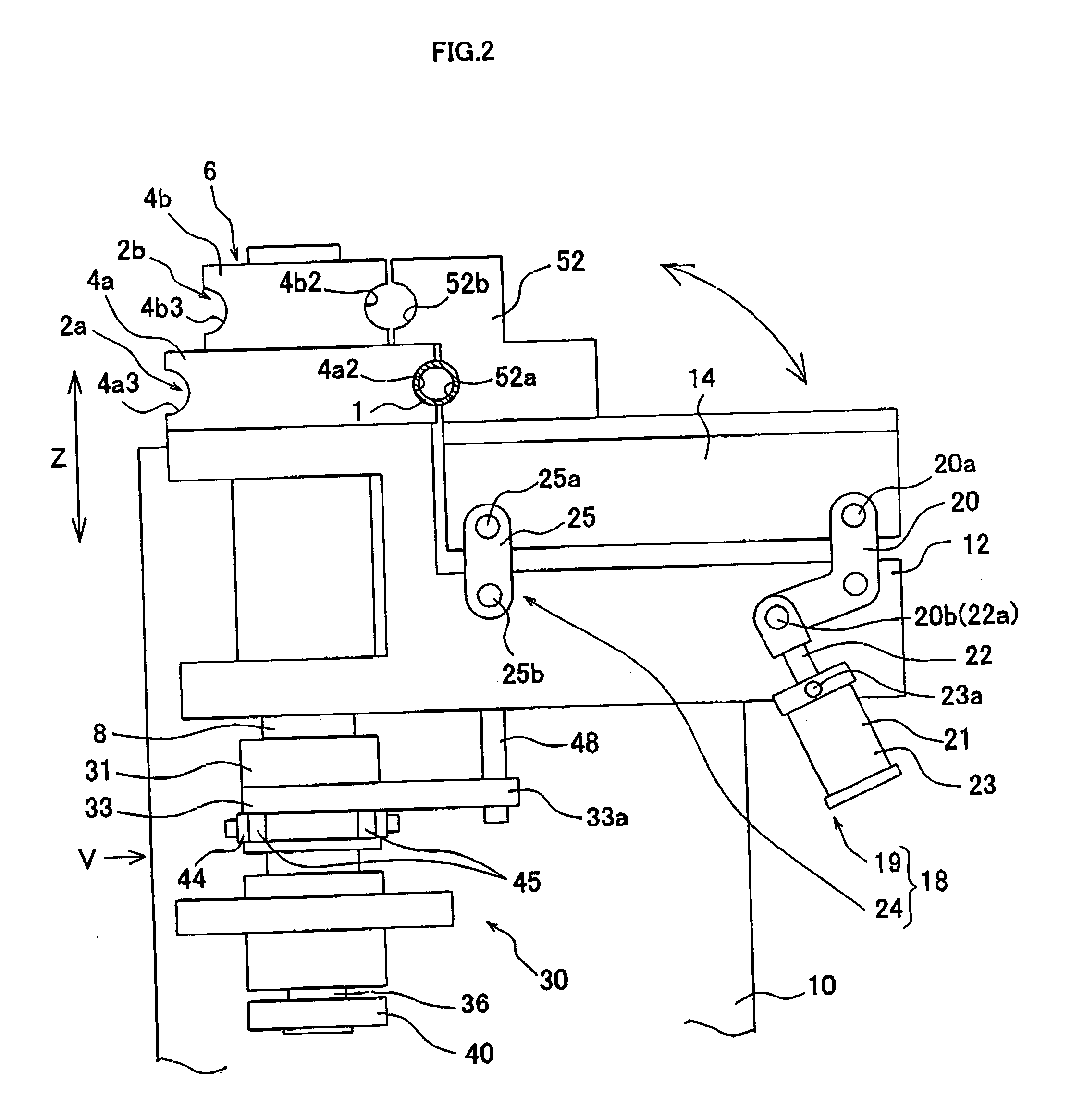

[0056] As shown in FIGS. 1 to 4, a bending device 100 of the present embodiment comprises a bending die 6, a clamping die 50, a right pressure die 56, a left pressure die 58, and a chuck 80. The clamping die 50 includes a clamping die 52 for right bend and a clamping die 54 for left bend.

[0057] As later explained, the bending device 100 bends a workpiece 1, such as a longitudinal pipe, to the right side (i.e., a direction of arrow R in FIG. 9A), by cooperation between the bending die 6, the clamping die 52 for right bend, and the right pressure die 56. Also, the bending device 100 bends the workpiece 1 to the left side (i.e., a direction of arrow L in FIG. 10A), by cooperation between the bending die 6, the claming die 54 for left bend, and the left pressure die 58.

[0058] The bending die 6 is provided in its outer shape with a plurality of bending grooves 2a, 2b (see FIGS. 2 and 4) in tiers, as a plurality of bending die contact portions corresponding to a plurality of bending sha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com