Aluminum foil cups for covering laboratory vessels

a technology of aluminum foil and laboratory containers, which is applied in the direction of laboratory glassware, liquid handling, and closure using stoppers, etc., can solve the problems of awkward and time-consuming, foreign materials could be transported or leached, and the conventional laboratory means for handling and cutting regular aluminum foil, etc., to achieve the effect of reducing any excessive frictional force and easy separation from on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Definitions. As used in this description and the accompanying claims, the following terms shall have the meanings indicated, unless the context otherwise requires:

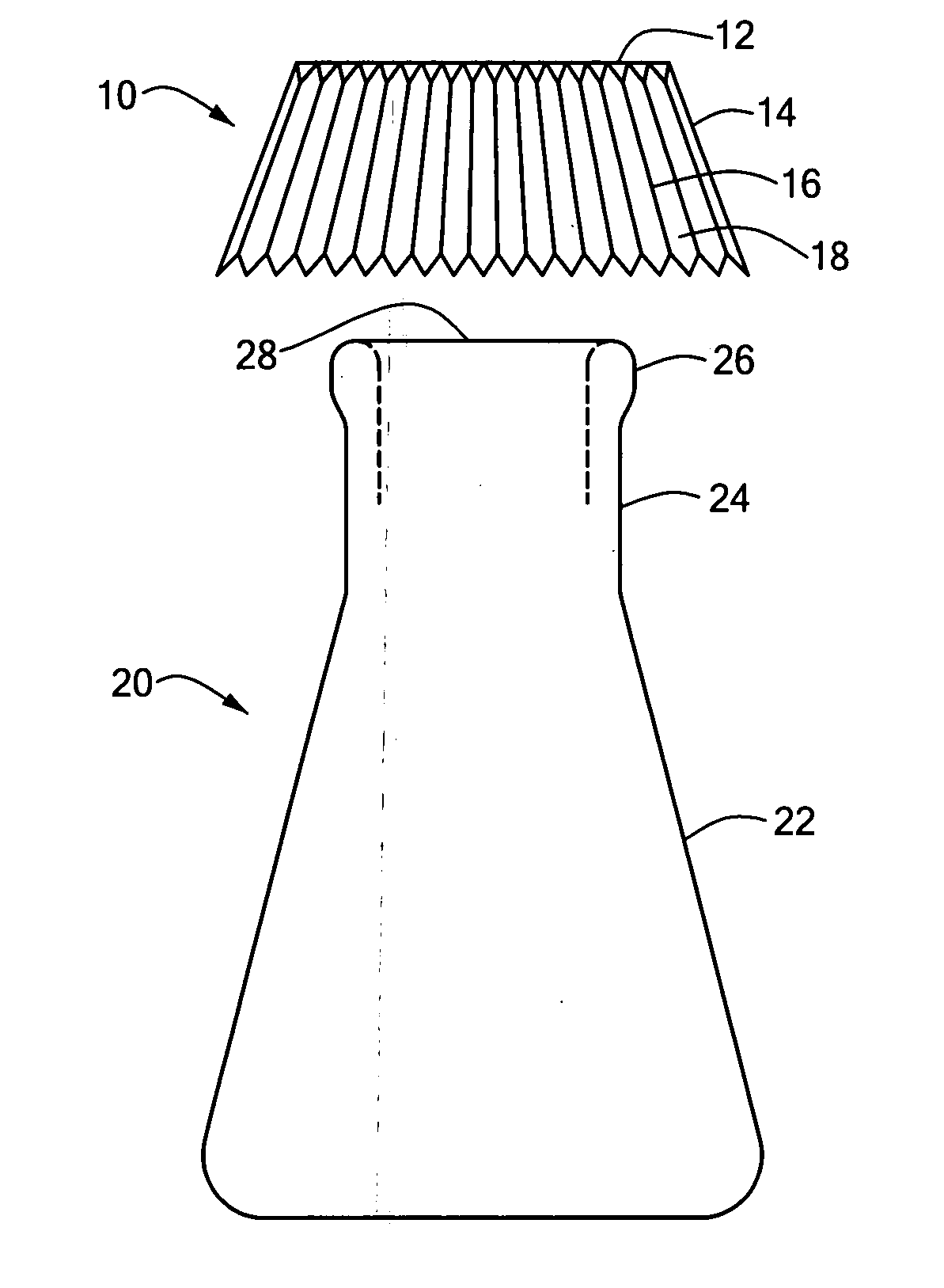

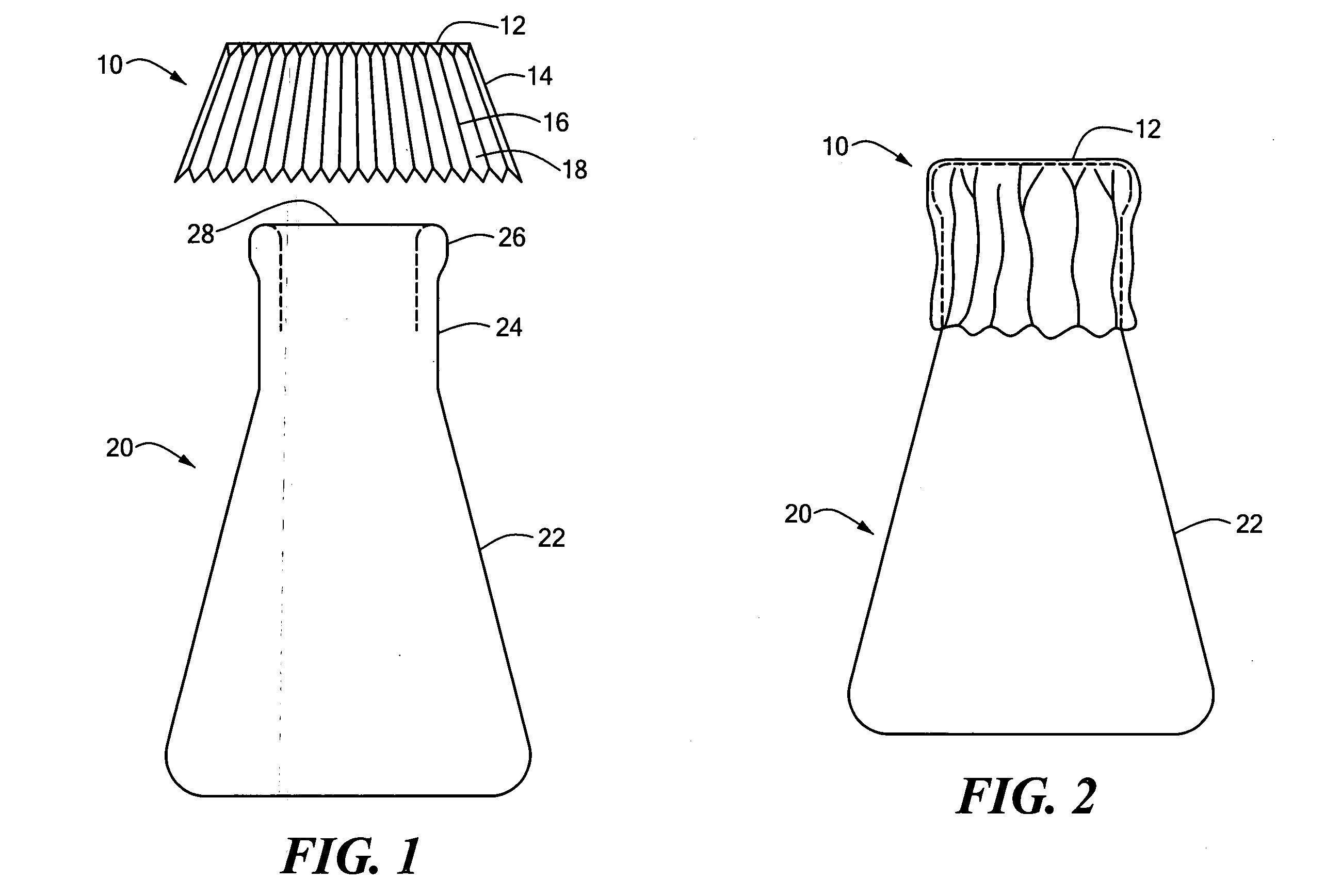

[0027] The phrase “covering the opening in a laboratory container” as used in the present invention means that the foil cup used in this regard, is inverted so that the interior of the cup is facing downward, and the cup is placed directly over the opening, i.e., mouth, of the container (regardless of whether the opening is the small mouth opening of a test tube, or the larger opening of a flask or beaker). The cup is selected to be of a sufficient size (diameter and sidewall height) so that the foil extends beyond the lip of the opening in the container and further extends downward along the neck or sidewall of the container at least 1 / 4 inch or so. Given the flexibility of the foil cup and its pleats, the cup may be extended in its diameter or alternatively compressed inward to provide a larger or smaller coverin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com