Fade protector

a protective layer and protective glass technology, applied in the field of protective glass, can solve the problems of high cost of conservation glass, and achieve the effect of convenient application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

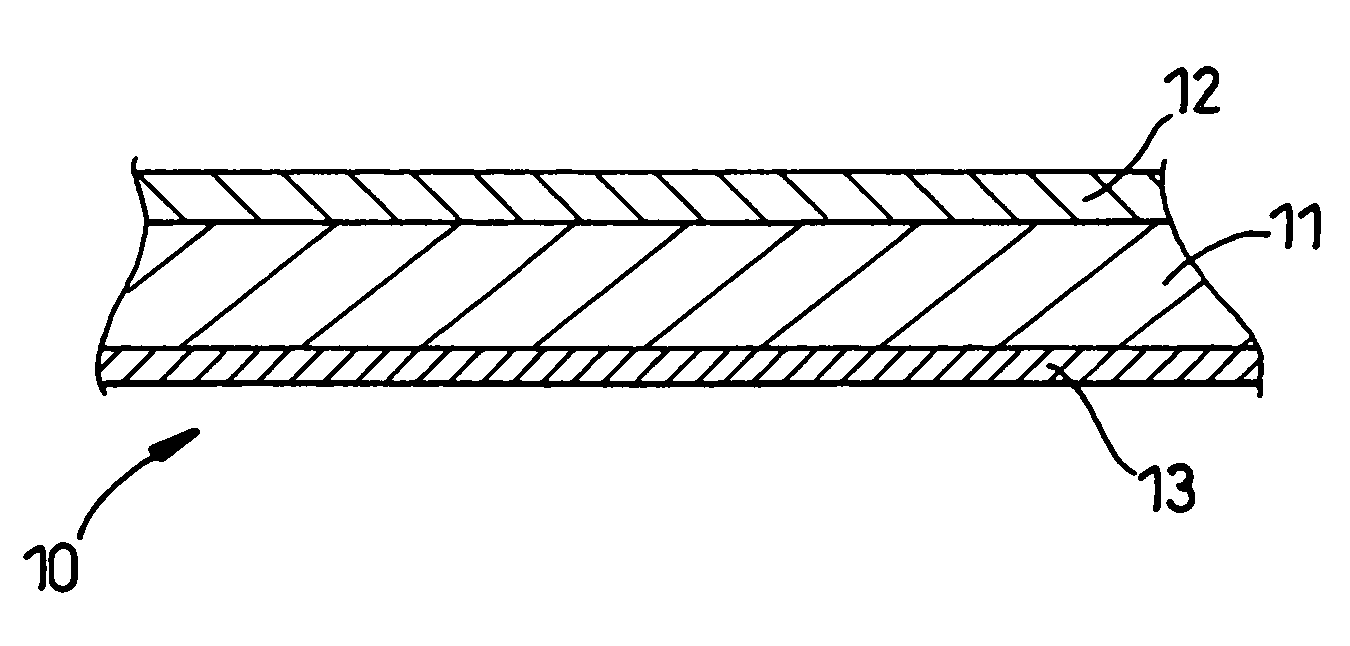

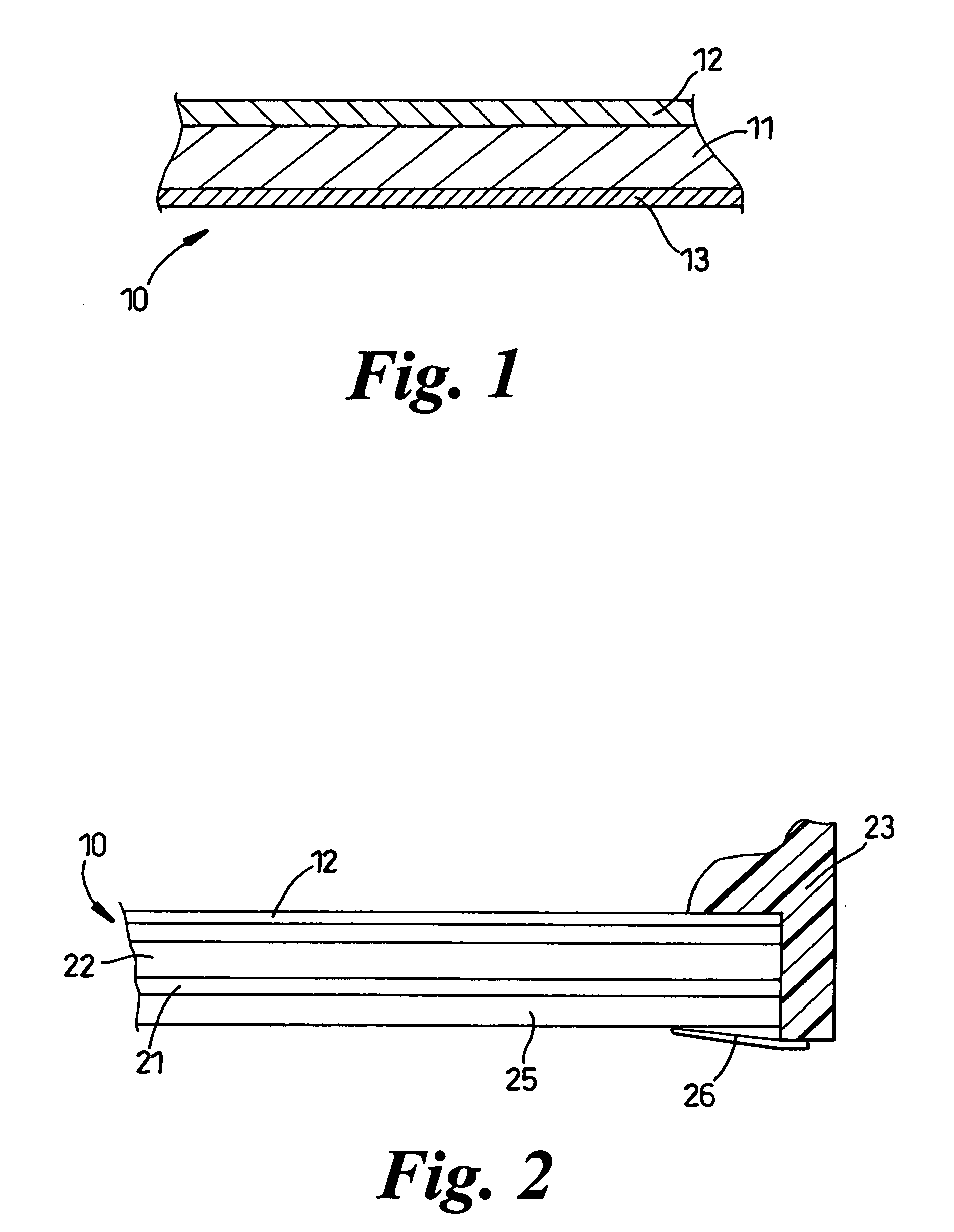

[0033] With reference to FIG. 1 there is shown a fade protector 10 comprising a suitable transparent polymeric film layer 11 including a TJV absorber. A suitable transparent film is a polyester film, preferably a polyethyleneterephtbalate (PET) film treated with a UV absorber as described in U.S. Pat. No. 6,221,128 so as to absorb up to 99% of UV radiation. A suitable PET film is DuPont Teijin Films' Melinex 454 or LIX 112. The PET film layer is provided with an anti glare coating 12 on one side thereof and with a paper based mask 13 on the other side thereof

[0034] The mask 13 is preferably release liner having a low tack adhesive on one side which in use adheres to the back surface of the PET layer to protect the film from scratching or marking prior to use. A suitable release liner is a polyethylene coated paper with a low tack adhesive thereon and a suitable product is available from Felix Schoeller Inc. of Pulaski, N.Y. under the designation 861b HDPE release liner,

[0035] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

| Gloss | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com