Structure for supplying hot air for drying clothes in drum type washing machine and operation control method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

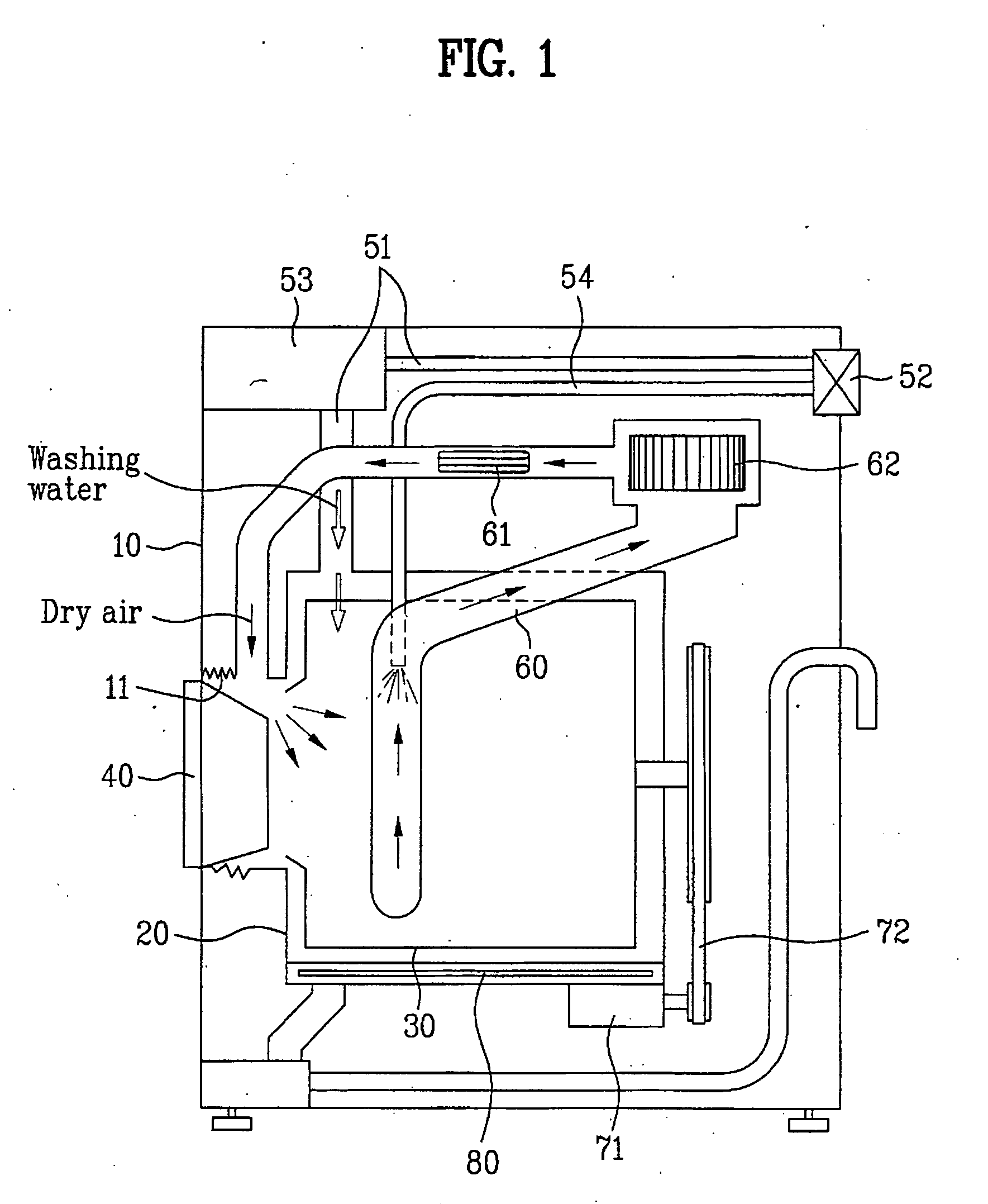

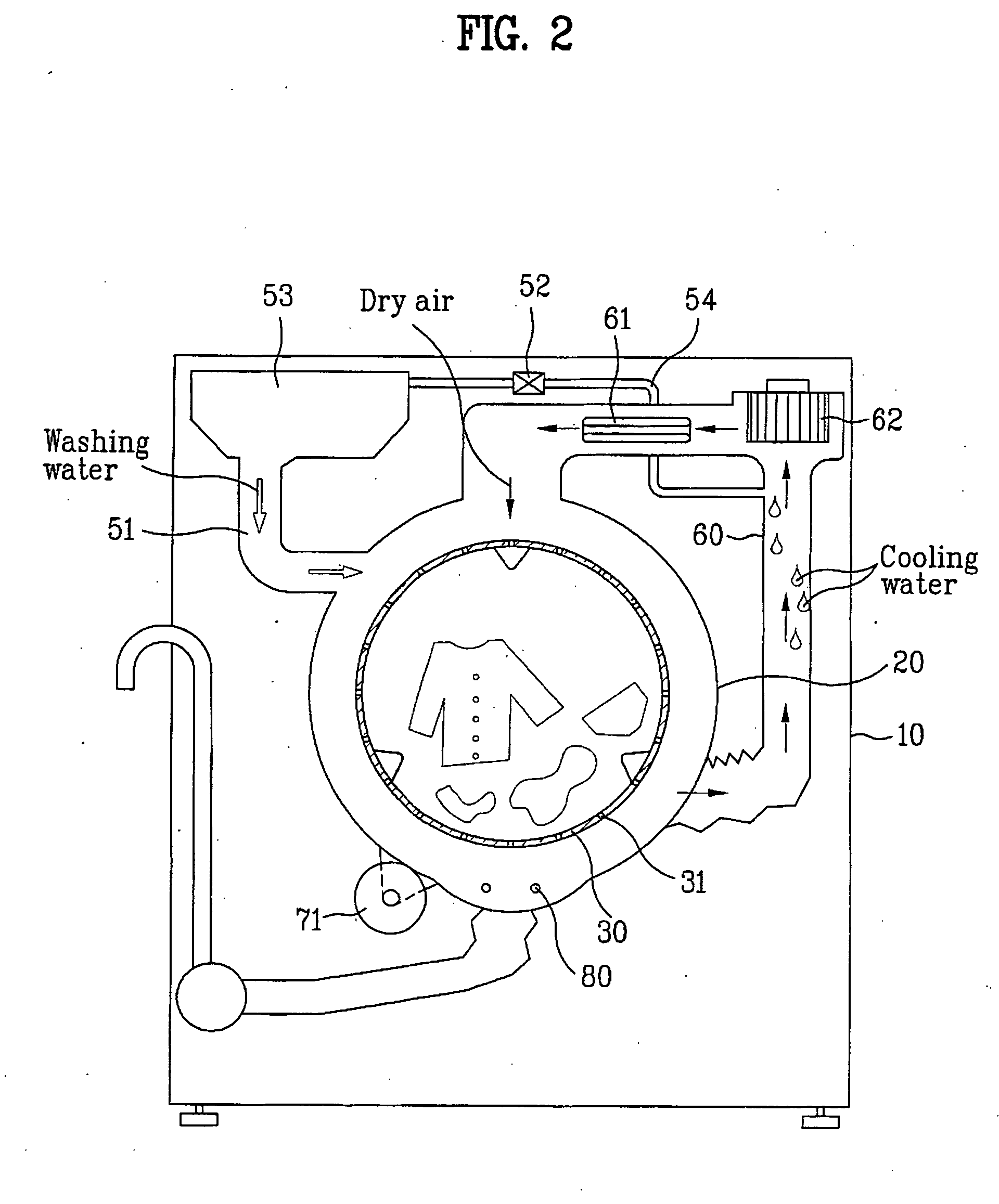

[0078] The hot air flows along a direction of a drum driving shaft line in the drum, for which it is preferable that the hot air is supplied from a front to a rear of the drum, or vice versa, like the

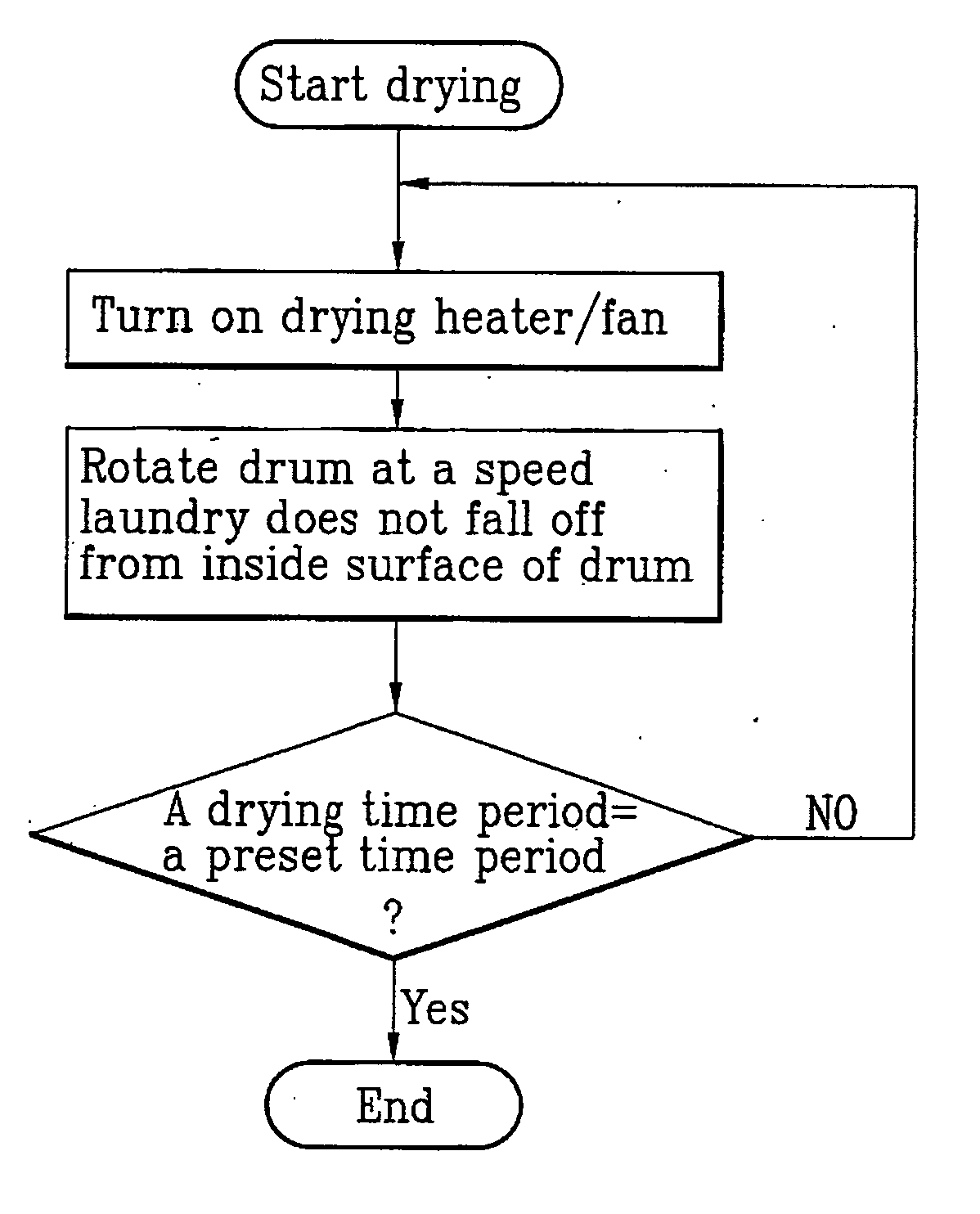

[0079] Alike the first embodiment, the dry progressing step may include a section in which the rotation speed of the drum is maintained at a speed equal to, or higher than a speed (for an example, 100 rpm) enough to keep the laundry in the drum to be attached to, and not to fall off from, but not to be attached closely to, the inside circumferential surface of the drum, and a section in which the rotation speed of the drum is reduced to a low speed (about 20˜30 rpm) at which the laundry in the drum is unable to be attached to the inside circumferential surface of the drum.

[0080] Thus, the embodiment enables to reduce a drying time period as the drying heater and the fan are turned on starting from the inertial rotation of the drum following finishing of spinning to supply hot air, and ...

second embodiment

[0082] If the drum washing machine of the first or second embodiment is further provided with means in the drum 30 for determining dryness (for an example, an electrode sensor: not shown) of the laundry, the following operation control method is also viable.

[0083] That is, a method for controlling operation of a horizontal or tilt drum washing machine in accordance with a third preferred embodiment of the present invention includes the steps of measuring dryness of laundry in the drum in a state the drum is stationary after finish of spinning, supplying hot air to an inside of the drum while rotating the drum at a speed equal to or higher than a speed at which an outward acceleration acting on a point of an inside circumferential surface of the drum in a radial direction of the drum is equal to an acceleration of the gravity if the dryness measured in above step is below a preset dryness, and supplying hot air to an inside of the drum while rotating the drum at a reduced speed at wh...

fourth embodiment

[0098] The finish of drying may be simply set to finish the drying at the time the set time is reached. Or alternatively, the drying may be finished by setting a drying time period, measuring the dryness when the set drying time period is reached, and extending the drying time period according to the measured dryness. Or alternatively, regardless of a set drying time period, the finish of drying may be determined with reference to a preset dryness which is different from the set dryness in the third or

[0099]FIG. 11 illustrates a graph showing a rotation speed of a motor for driving the drum, and turn on / off states of drying heater and fan while drying.

[0100] Referring to FIG. 8, it can be known that a section for progressing drying at a speed in which the laundry can not be attached to, but fall off from the inside surface of the drum in a state the drying heater and the fan are turned on, a section in which the drum driving motor is turned on to accelerate the drum to a speed high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com