Resonant arrangement for a linear compressor

a linear compressor and resonant technology, applied in the direction of positive displacement liquid engine, pump components, pumping, etc., can solve the problems of inability to properly fix, high price of flat springs, and relatively difficult to obtain flexible rods, etc., to achieve easy and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

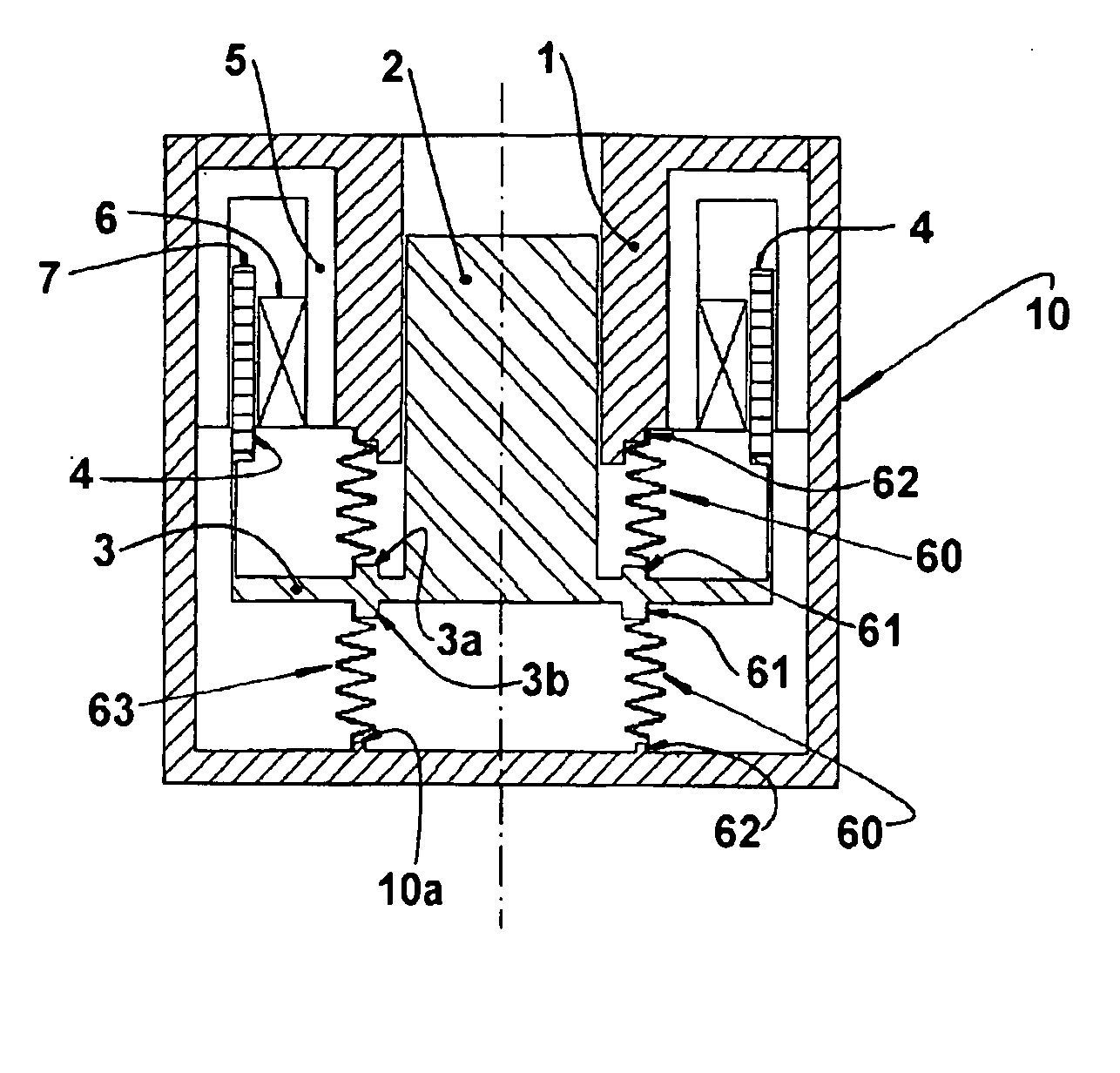

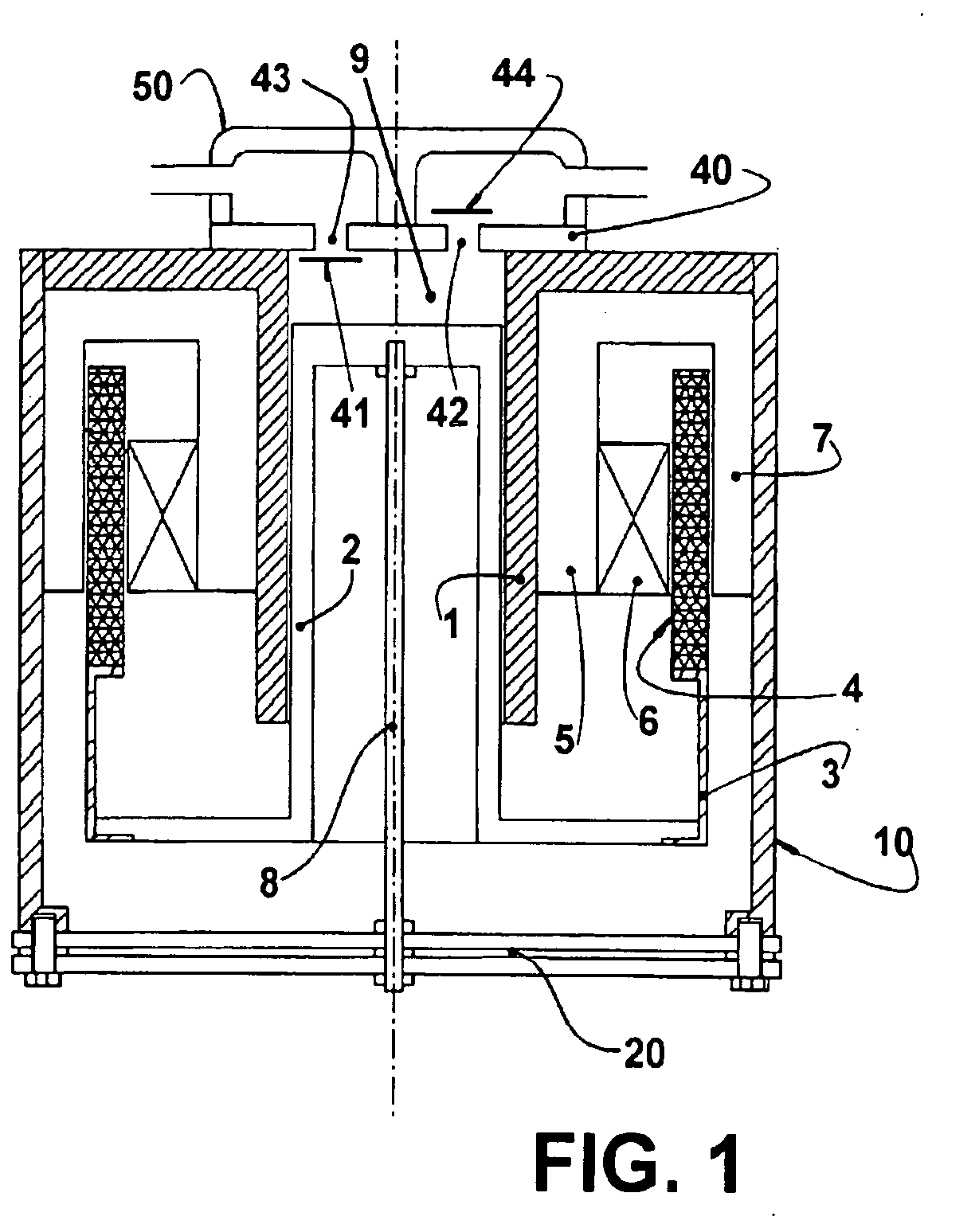

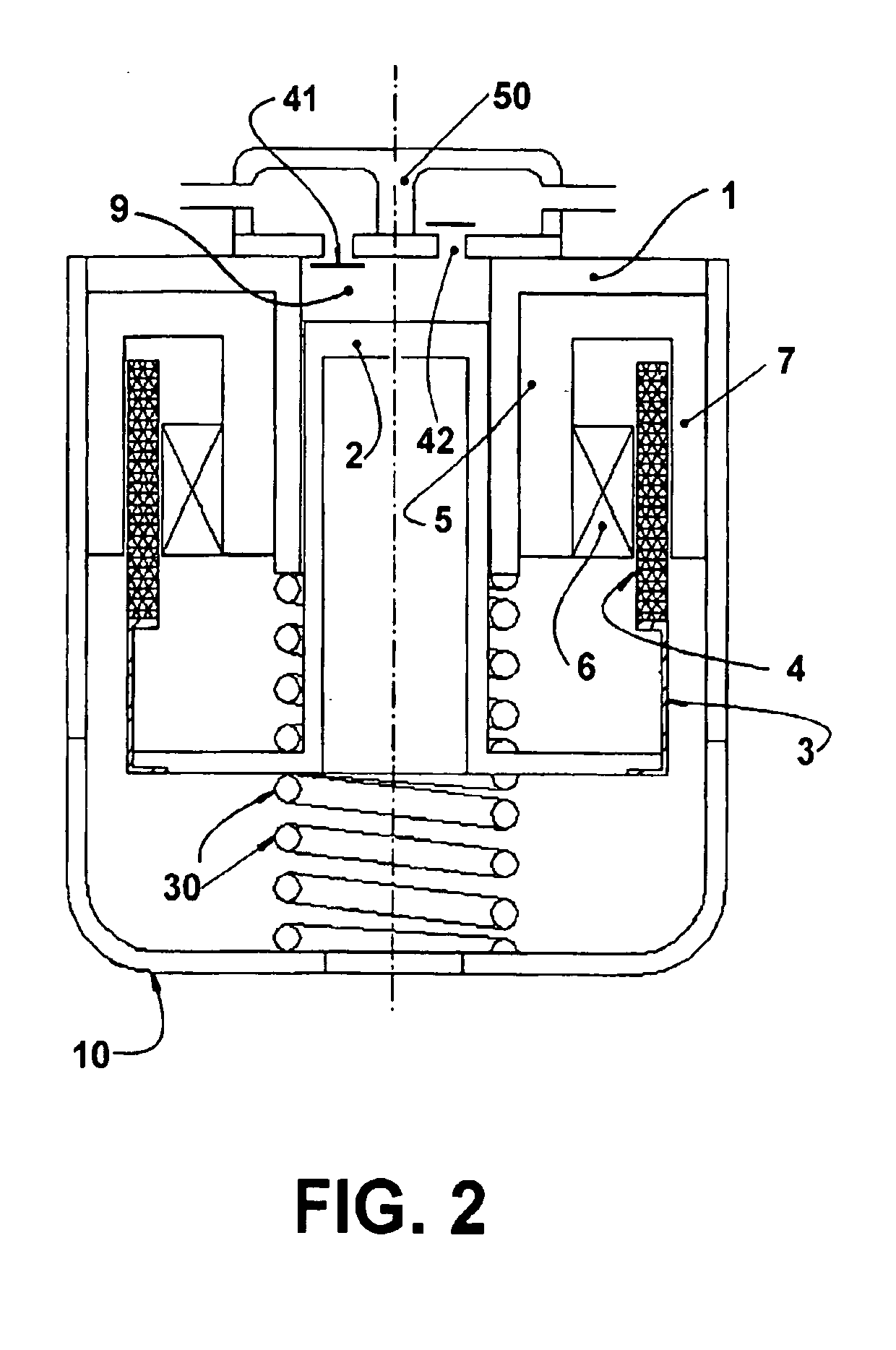

[0020] The present invention will be described in relation to a reciprocating compressor driven by a linear motor of the type used in refrigeration systems and comprising a motor-compressor assembly, including a non-resonant assembly formed by a linear motor and a cylinder 1, and a resonant assembly formed by a piston 2 reciprocating inside the cylinder 1, and an actuating means 3, external to the cylinder 1 and carrying a magnet 4 that is axially impelled upon energization of the linear motor, said actuating means 3 operatively coupling the piston 2 to the linear motor.

[0021] According to the prior art construction illustrated in FIGS. 1 and 2, the components mentioned above are mounted inside a hermetic shell 10.

[0022] As illustrated in the enclosed figures, the linear motor is mounted around the cylinder 1 and the piston 2 and comprises a stack of internal laminations 5 with a coil 6 inserted therein, and a stack of external laminations 7.

[0023] In the construction illustrated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com