Method of improving the flow conditions in an axial-flow compressor, and axial-flow compressor for carrying out the method

a compressor and flow condition technology, applied in the field of compressor technology, can solve the problems of narrow compressor working range, limited research on air-jet vortex generators, shock-induced separation of boundary layers,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The object of the invention is to specify a method and an axial-flow compressor with which the flow conditions on the suction side of the blades of the compressor can be improved with regard to the shock stabilization in a reliable and simple manner, in particular without the need for additional built-in components.

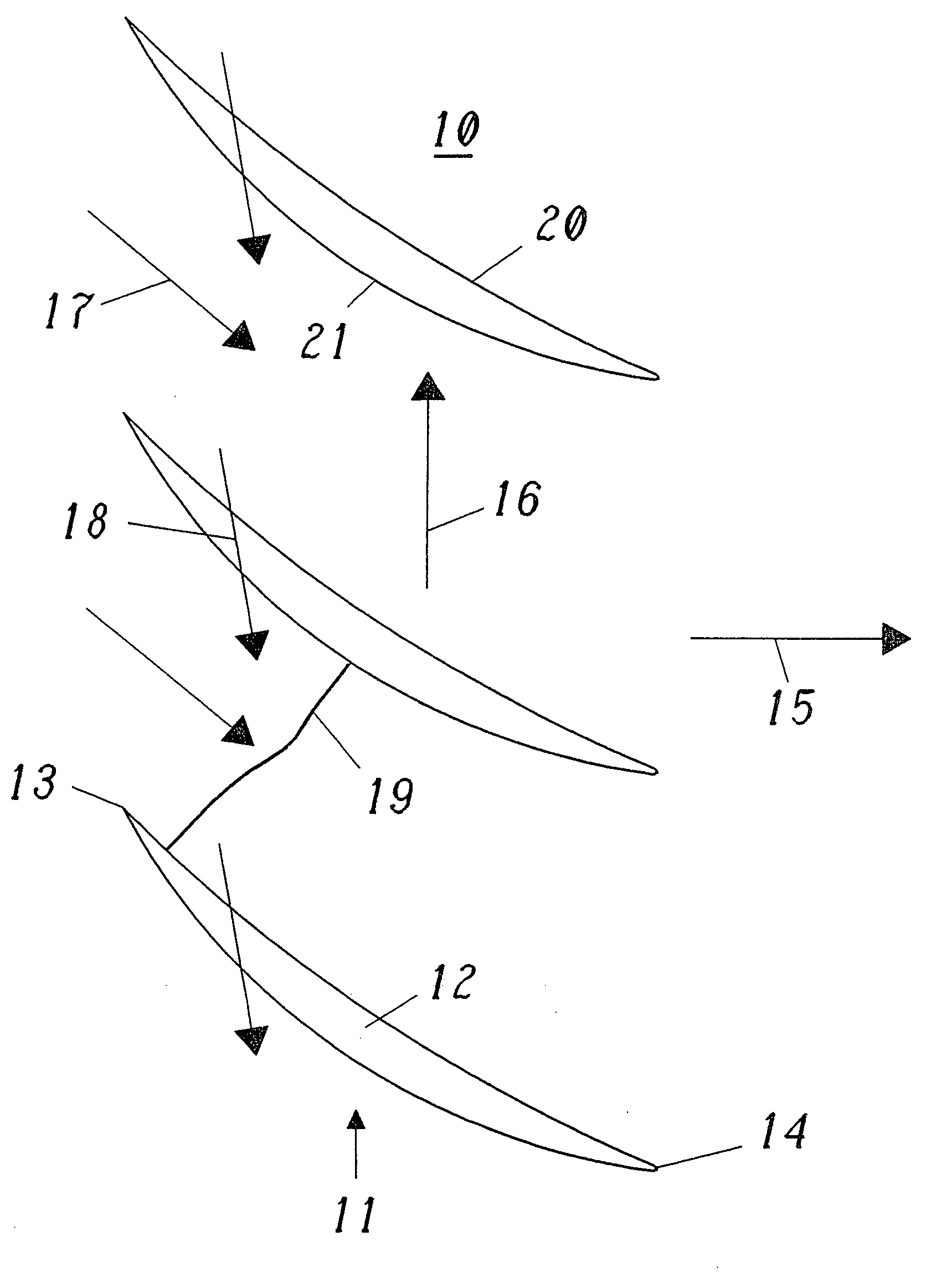

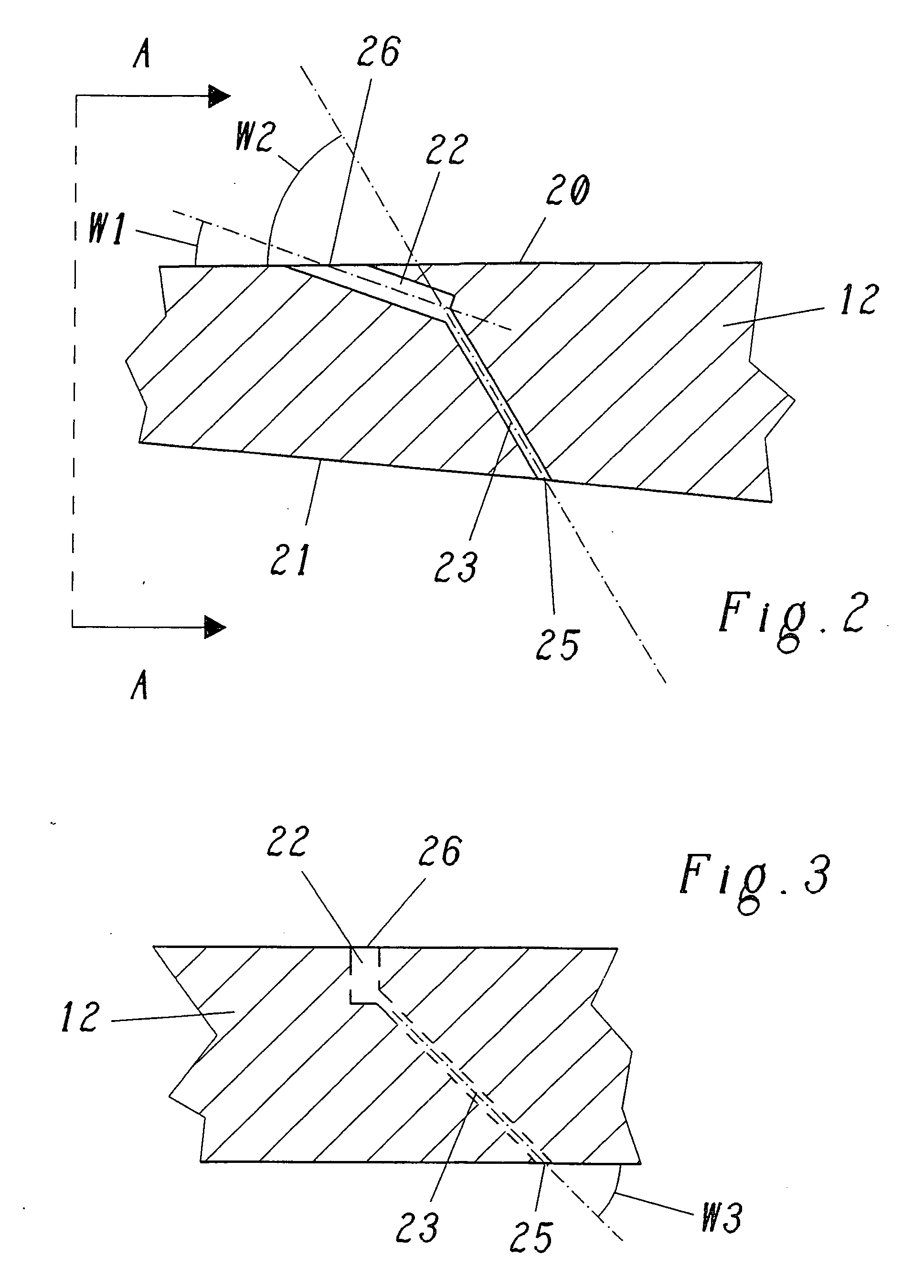

[0008] The object is achieved by all the features of claims 1 and 7 in their entirety. The essence of the invention consists in the fact that vortices running on the suction side in the direction of flow are generated by local air jets formed on the suction side. Due to the local air jets, the use of additional elements arranged on the blade surfaces is avoided and the risk of such elements falling off, with the resulting damage to following stages, is removed.

[0009] According to a preferred configuration of the method according to the invention, to form the local air jets, air having a higher pressure relative to the environment is discharged from first openings...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com