Applicator and method for in-mold coating

a technology of in-mold coating and nozzle, which is applied in the direction of liquid surface applicators, coatings, other domestic articles, etc., can solve the problems of operators coating the uncoated parts, difficult-to-reach areas of mold, and difficult-to-reach areas of undercut mold portions 20

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

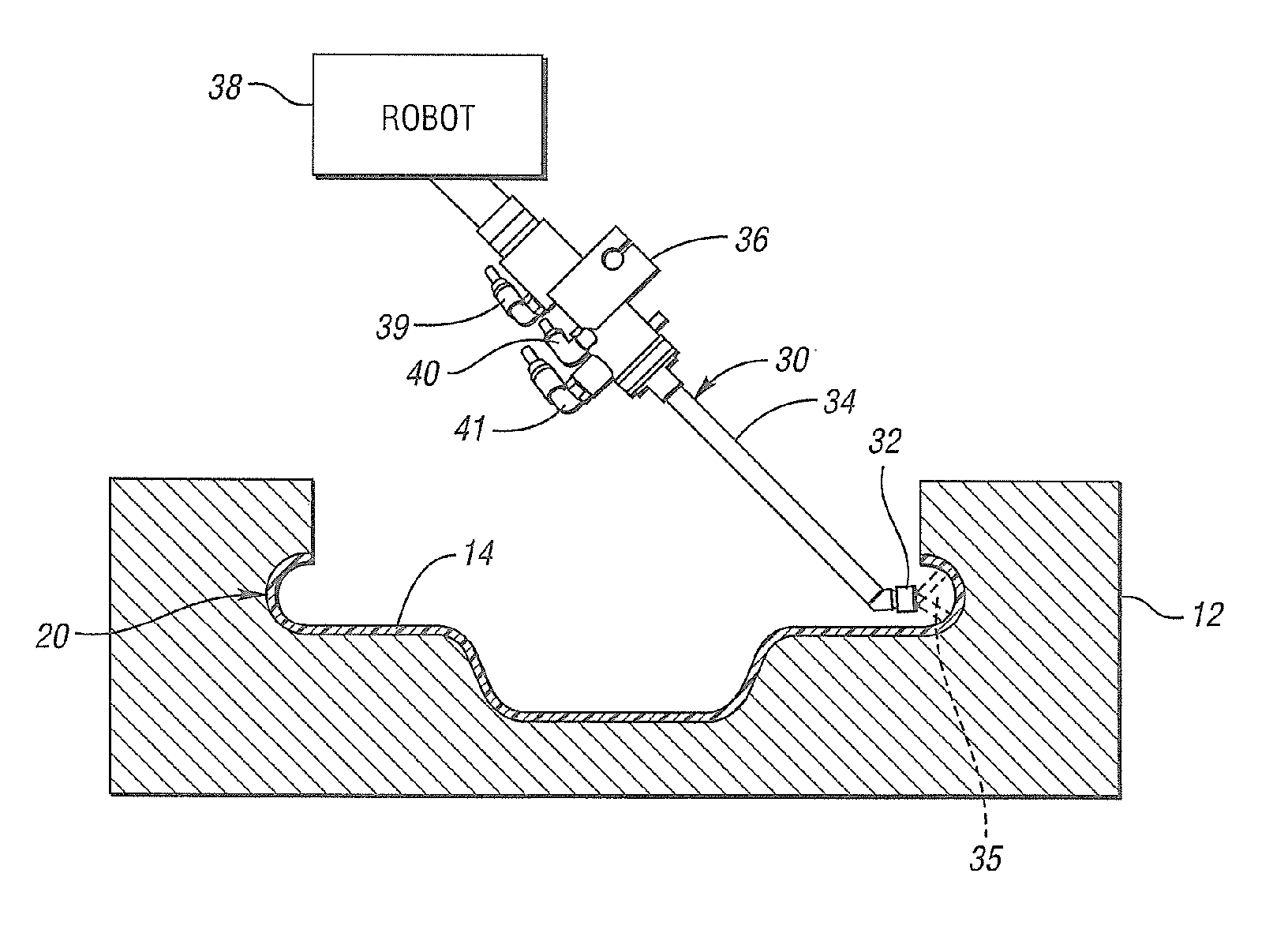

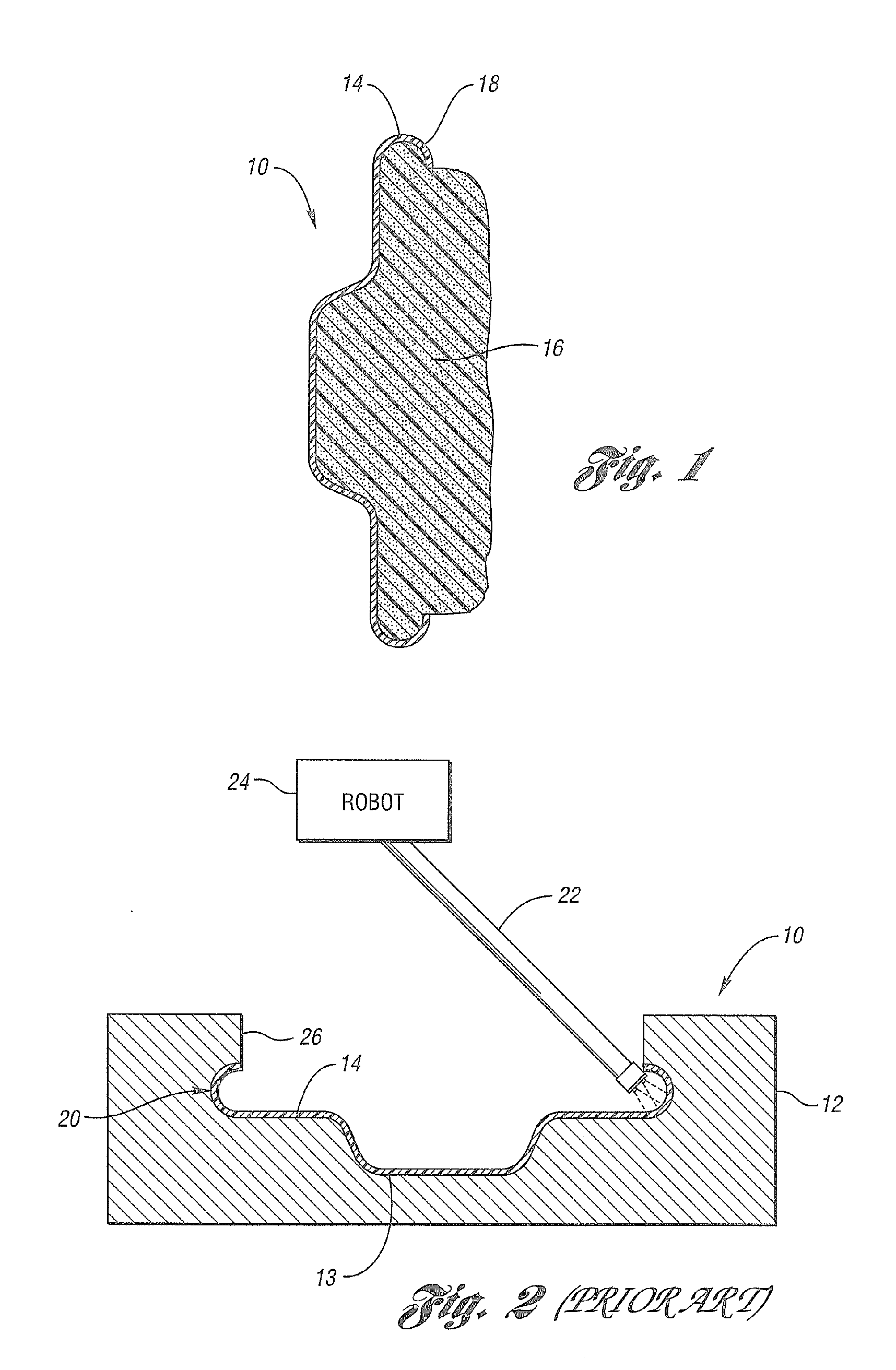

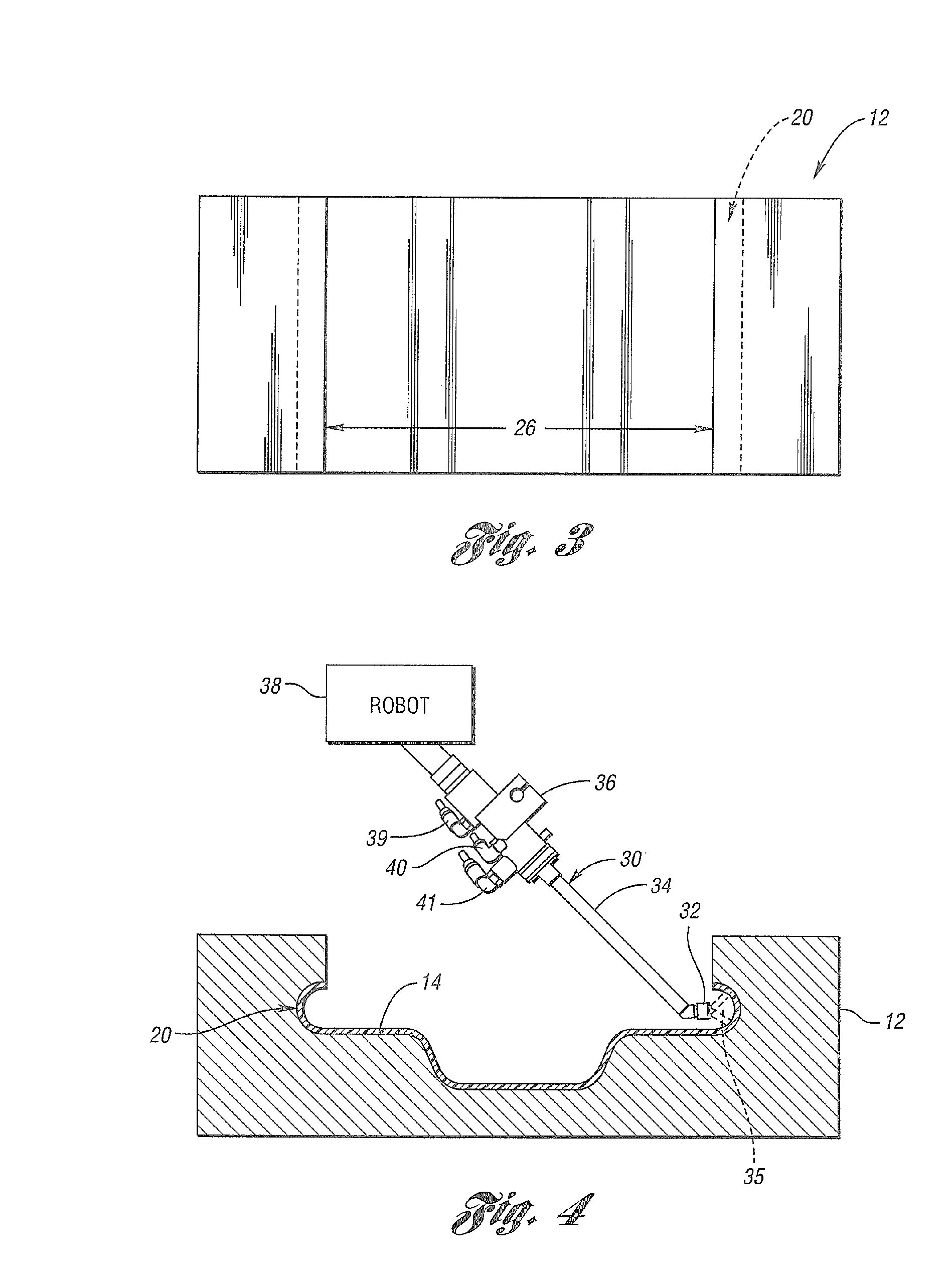

[0023]FIG. 4 shows an improved applicator device or applicator, according to the invention, for applying a coating to mold 12. The applicator of the invention is hereinafter referred to with reference numeral 30, and can be used in any number of applications in which it is desirable to spray a coating onto a mold. One area of interest is in processes used to manufacture soft interior components for automotive vehicles, like the skin making process and foam-in-the-mold process used to manufacture instrument panel 10 shown in cross-section in FIG. 1. As described above, instrument panel 10 can be manufactured by spraying mold 12 with a coating such as polyurethane, polyvinylchloride, or other material to form a relatively thin covering type skin 14 that forms a covering panel for covering a soft foam material 16.

[0024] In either the skin making process or the foam-in-the-mold process, the applicator 30 may deliver either waterborne or solvent-borne, one component or two component, co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com