Disc brake

a disc brake and disc technology, applied in the direction of fluid actuated brakes, axially engaging brakes, mechanical devices, etc., can solve the problems of reducing production efficiency and cumbersome operation of forming the passage opening, and achieve the effects of high production efficiency, easy formation, and high degree of design freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Hereinbelow, embodiments of the present invention are described, referring to the drawings.

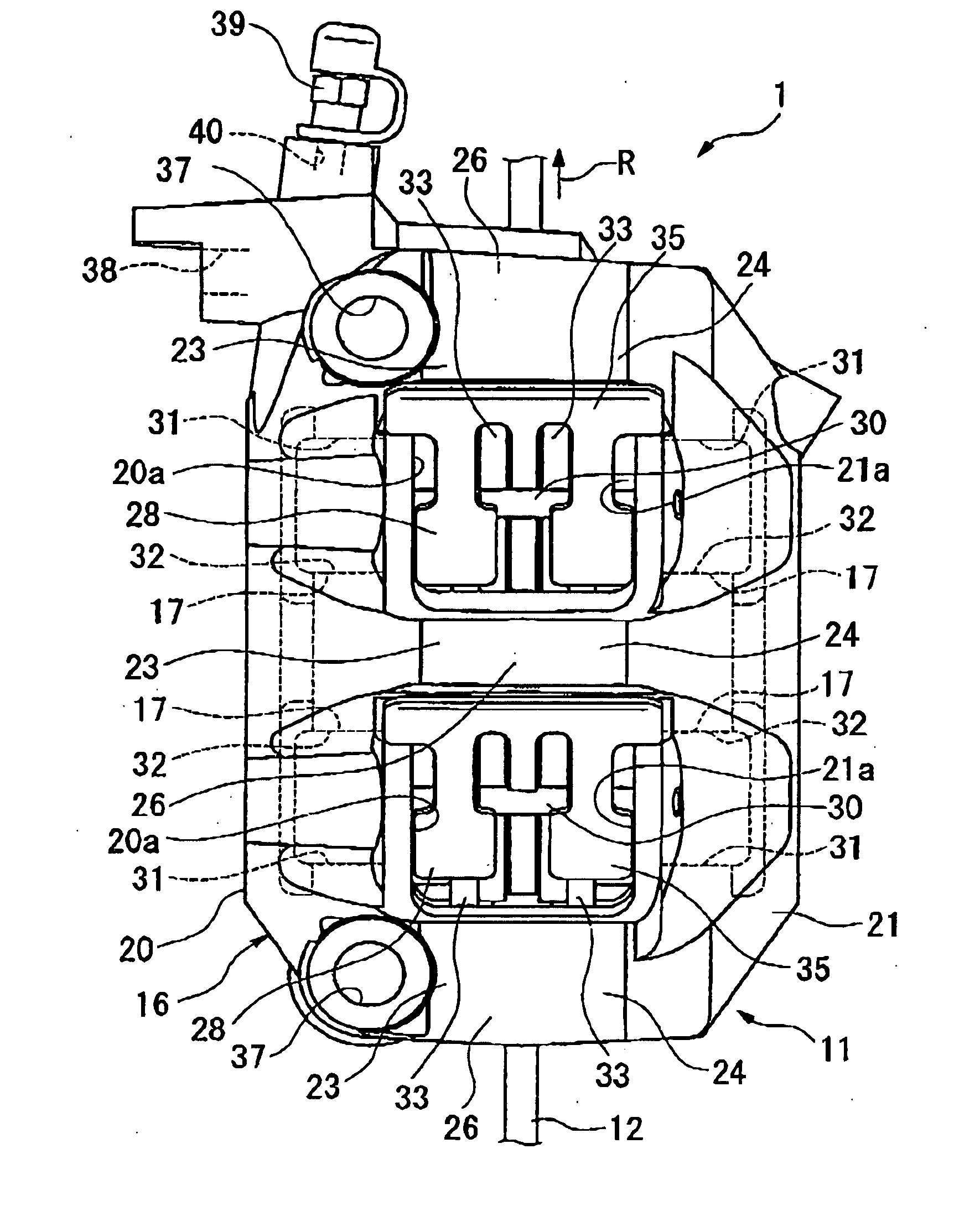

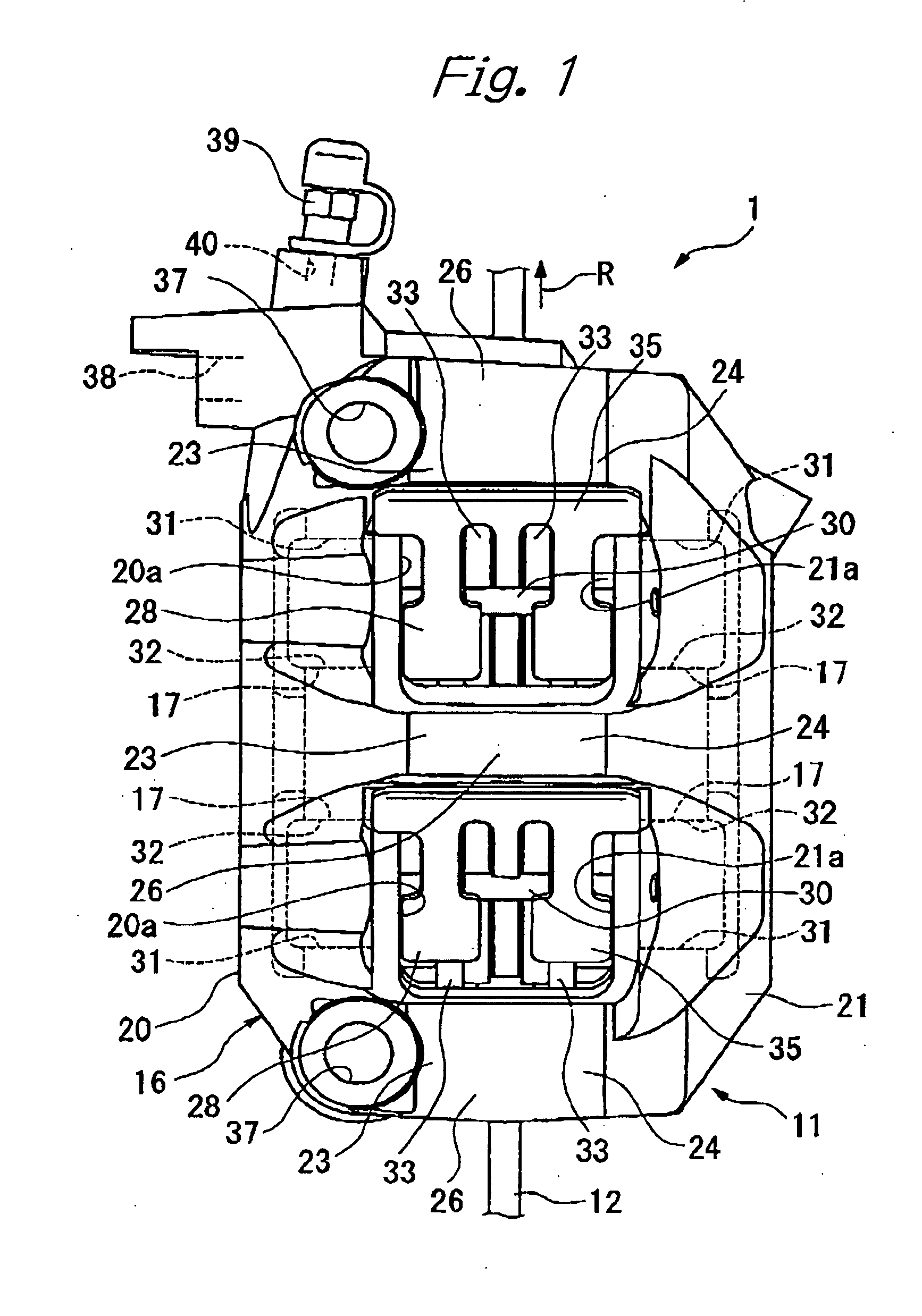

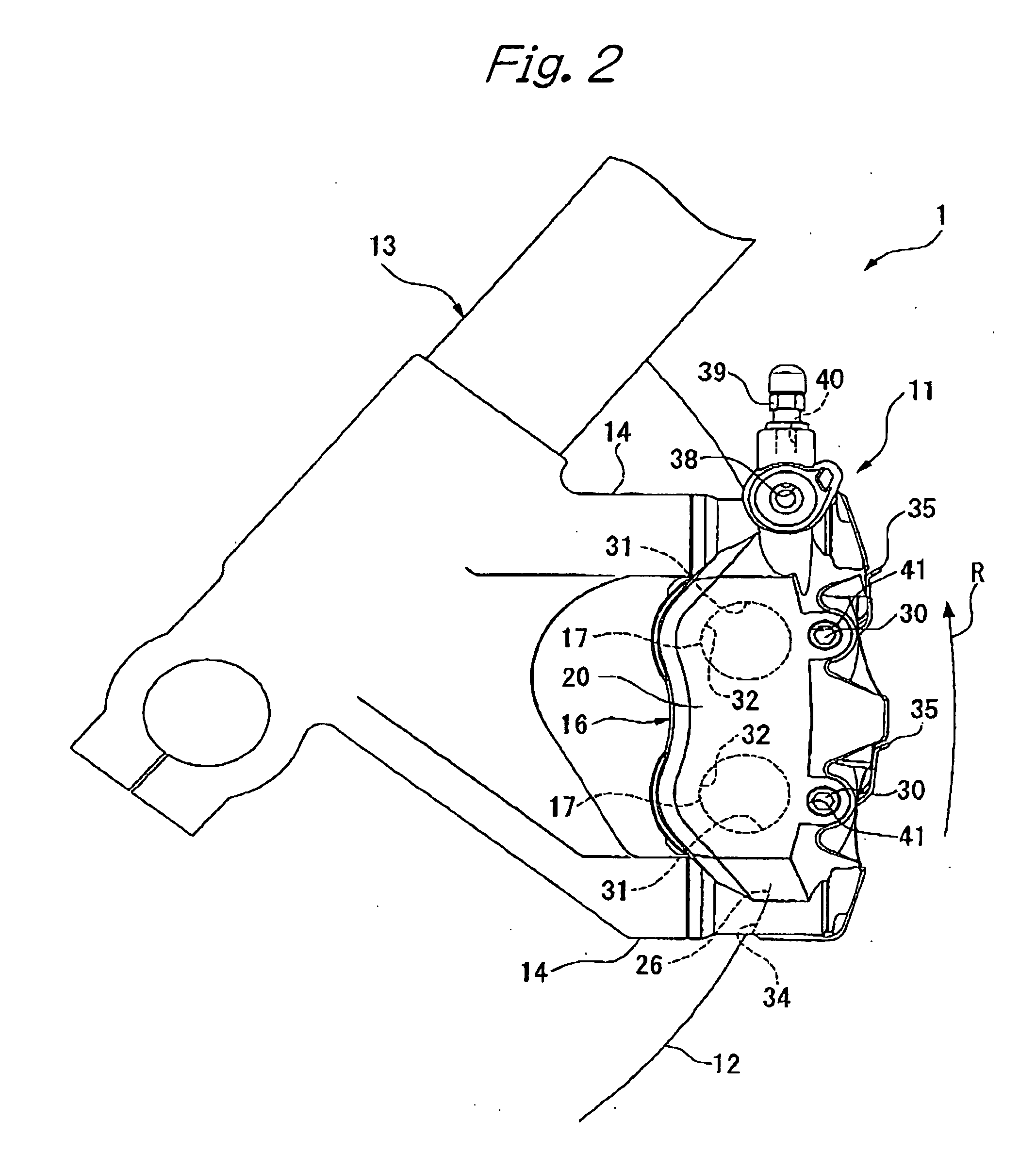

[0037] In FIGS. 1 and 2, reference numeral 1 denotes an opposed-piston type disc brake. A caliper 11 of this disc brake is an opposed-piston type caliper 11. The caliper 11 comprises a caliper body 16 which extends over a disc 12, as shown in FIG. 1, and which is mounted on a mount portion 14 of a front fork 13 as a non-rotational portion of a body of a vehicle (a motor cycle in this embodiment), as shown in FIG. 2. The caliper 11 further comprises a plurality of pairs (two pairs in this embodiment) of pistons 17 slidably provided in the caliper body 16, so as to face each other with the disc 12 being disposed therebetween. In the following description, a radial direction of the disc 12, an axial direction of the disc 12, a direction of rotation of the disc 12 refer to those in a state in which the caliper body is mounted on a vehicle body. In FIGS. 1 and 2, an arrow R indicates the di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| circumference | aaaaa | aaaaa |

| gravity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com