Fastening member and siding boards attachment structure using the fastening member

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

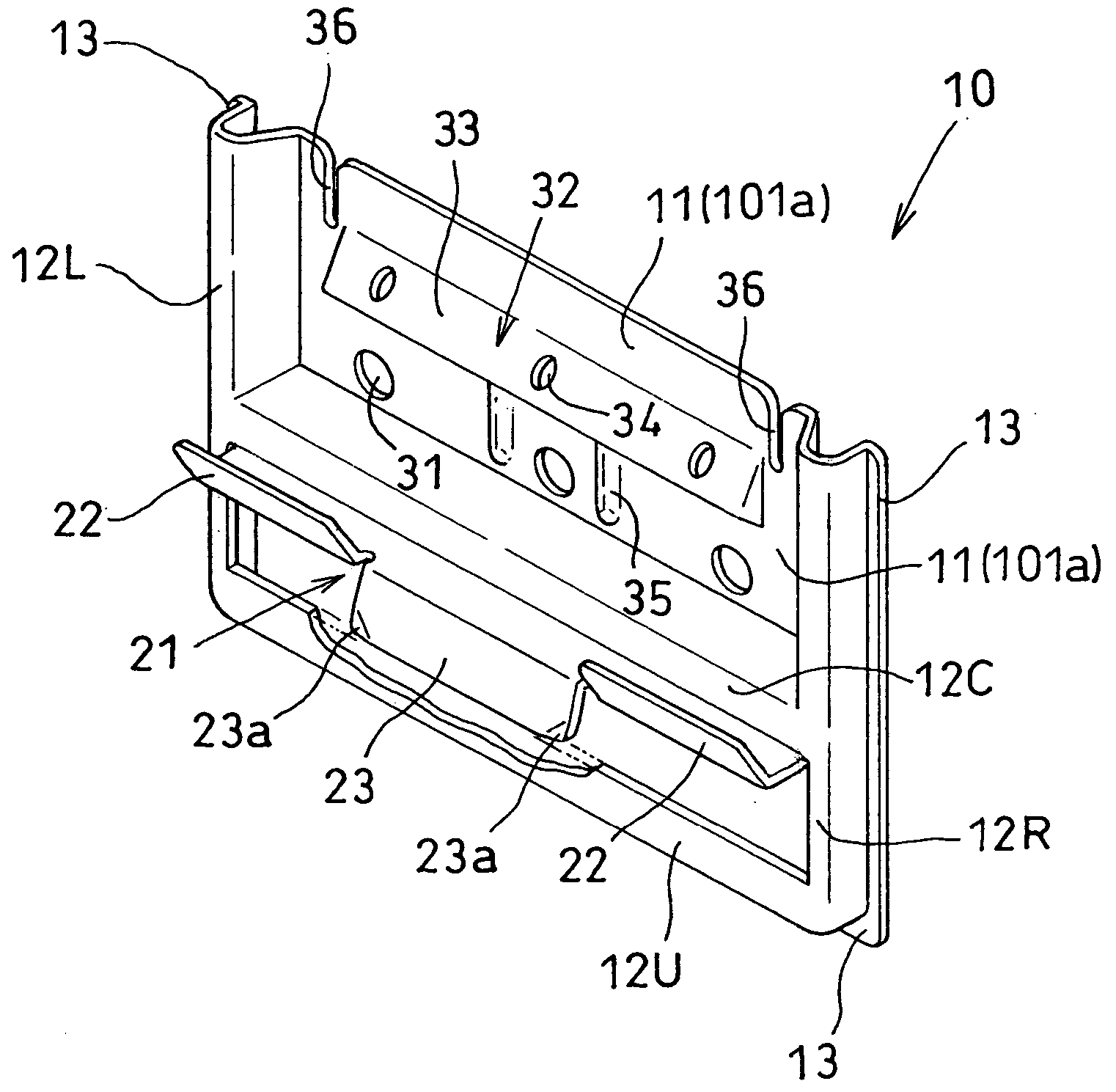

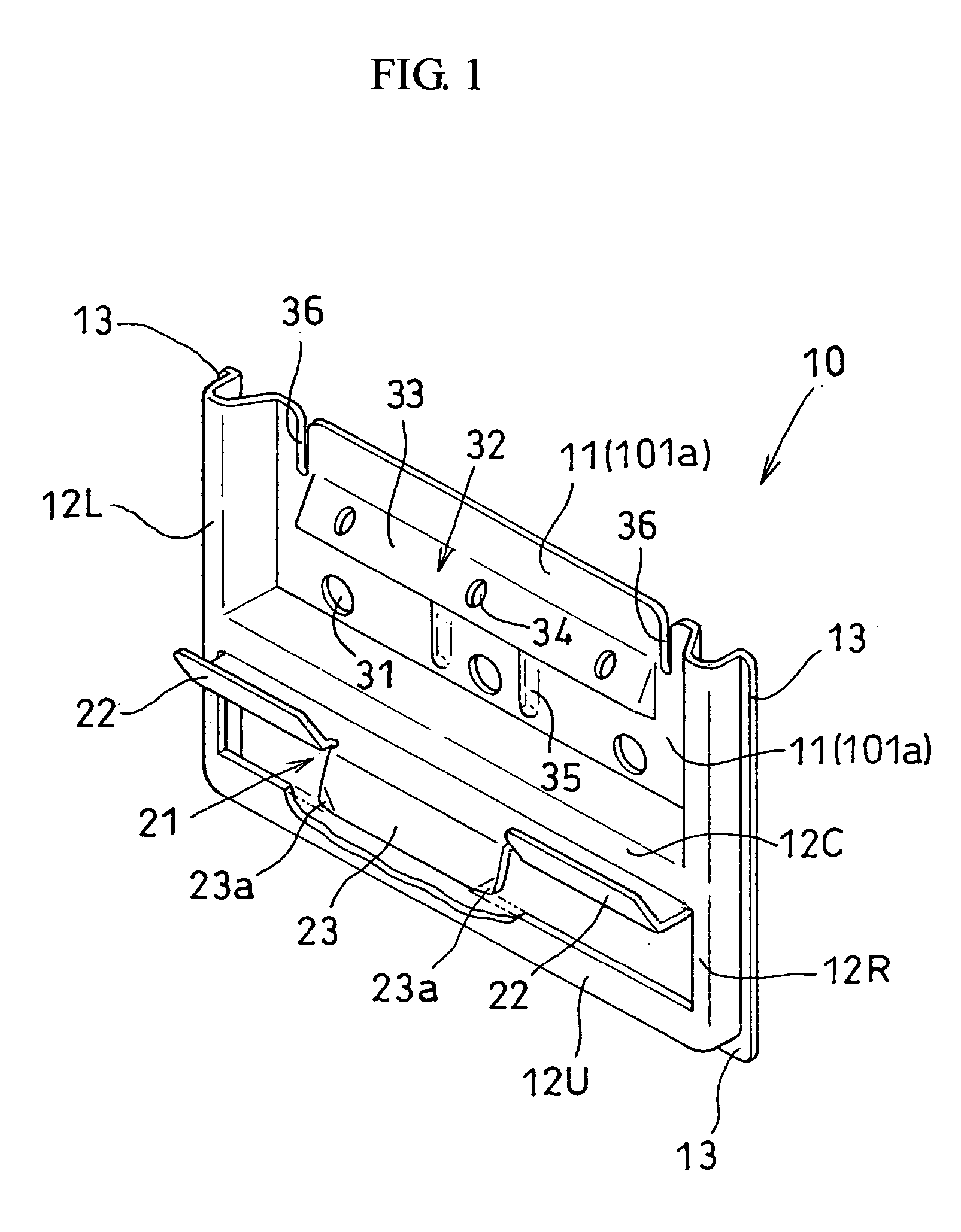

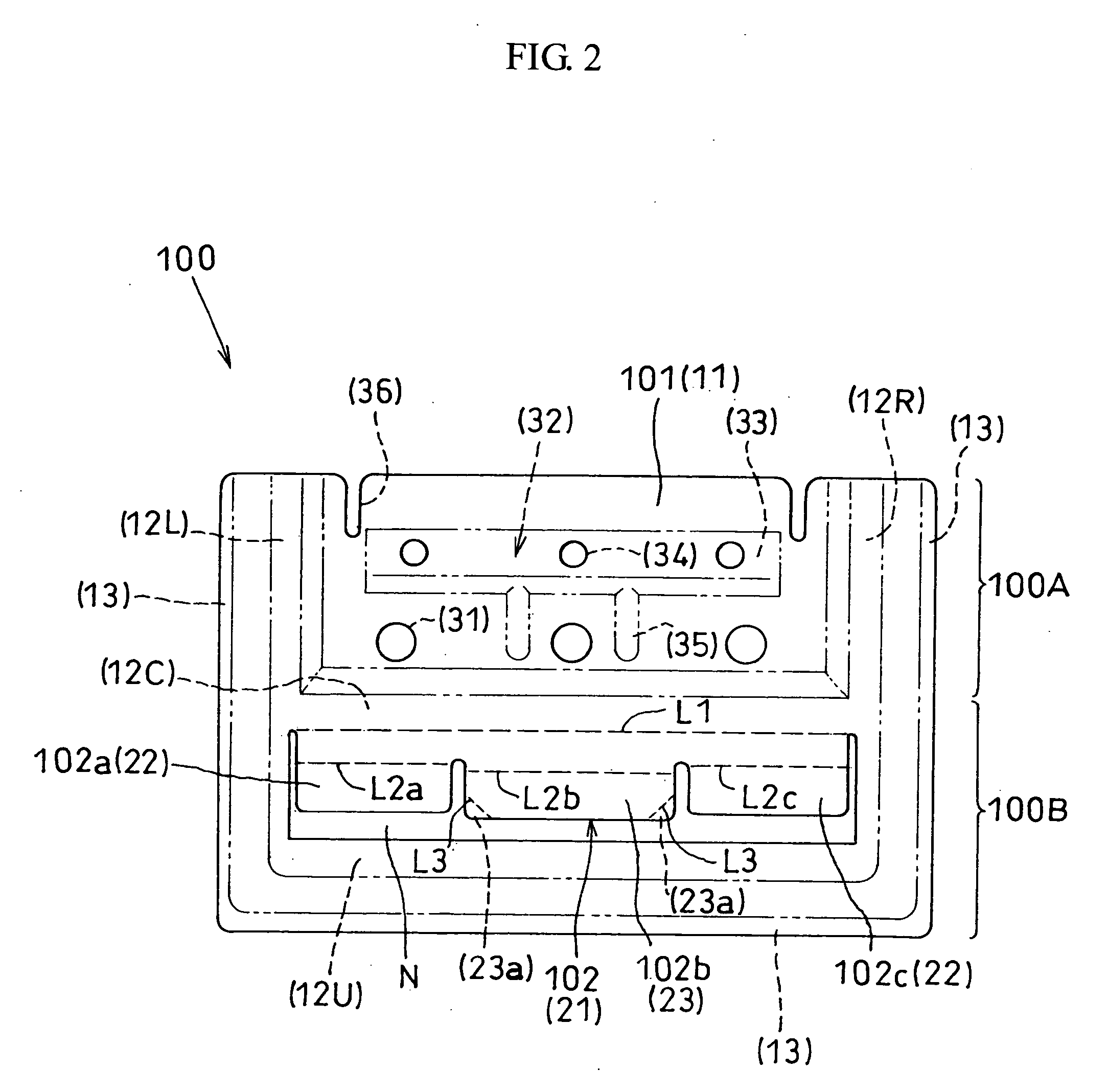

[0034] With reference to the drawings, a fastening member according to an embodiment of the invention and siding boards attachment structure utilizing the fastening member are described. FIG. 1 is a perspective view of the embodiment of the fastening member of the invention. FIG. 3 is a perspective view of the exterior wall structure utilizing the fastening member.

[0035] A fastening member 10 shown includes a left-side supporting portion 12L and a right-side supporting portion 12R on the sides thereof that will abut on the back surface of an exterior wall when fastened. The fastening member 10 also includes, in the intermediate region between the left- and right-side portions 12L and 12R, a substrate portion 11 that is to be fixed to a building frame. Below the substrate portion 11, the intermediate region includes a central support portion 12C that will abut on the back surface of a board when fastened. Further below, there are a locking portion 21 to be locked on the upper and lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com