Magnesium mirror base with countermeasures for galvanic corrosion

a technology of mirror base and magnesium mirror, which is applied in the direction of machine supports, instruments, other domestic objects, etc., can solve the problems of exacerbated inherent corrosion problems, reduced use of magnesium in automobiles, and metals including dissimilar metals, so as to prevent galvanic corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

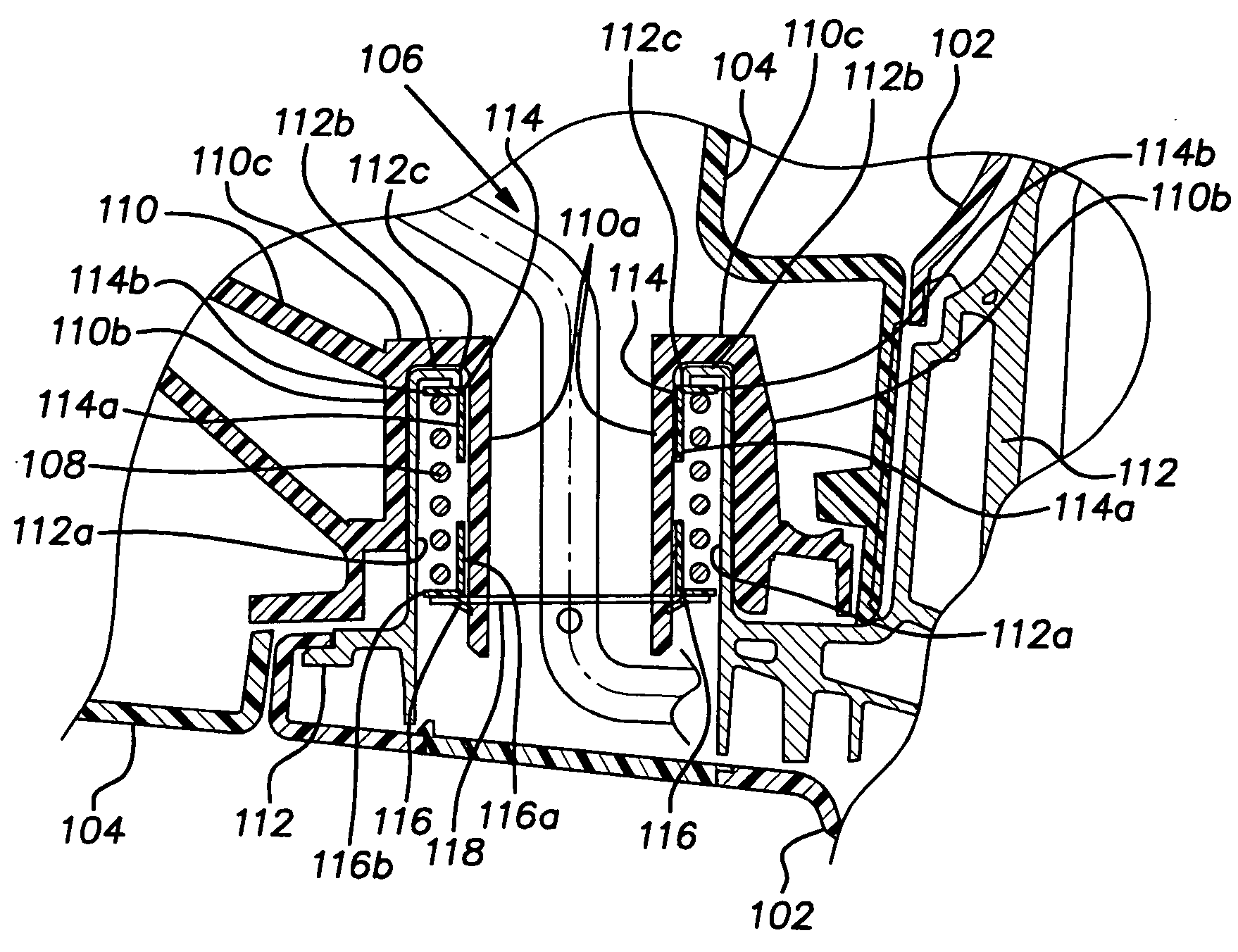

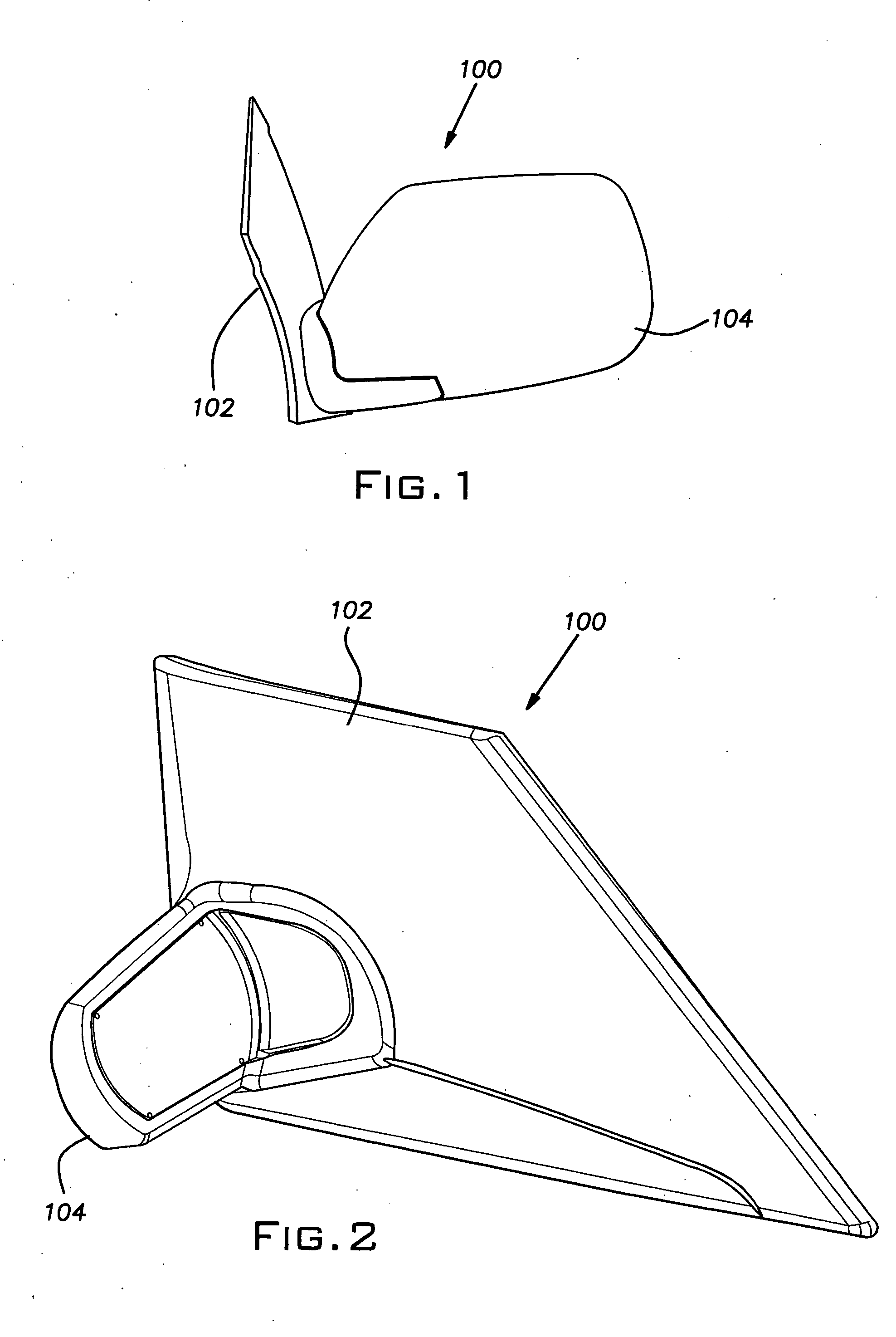

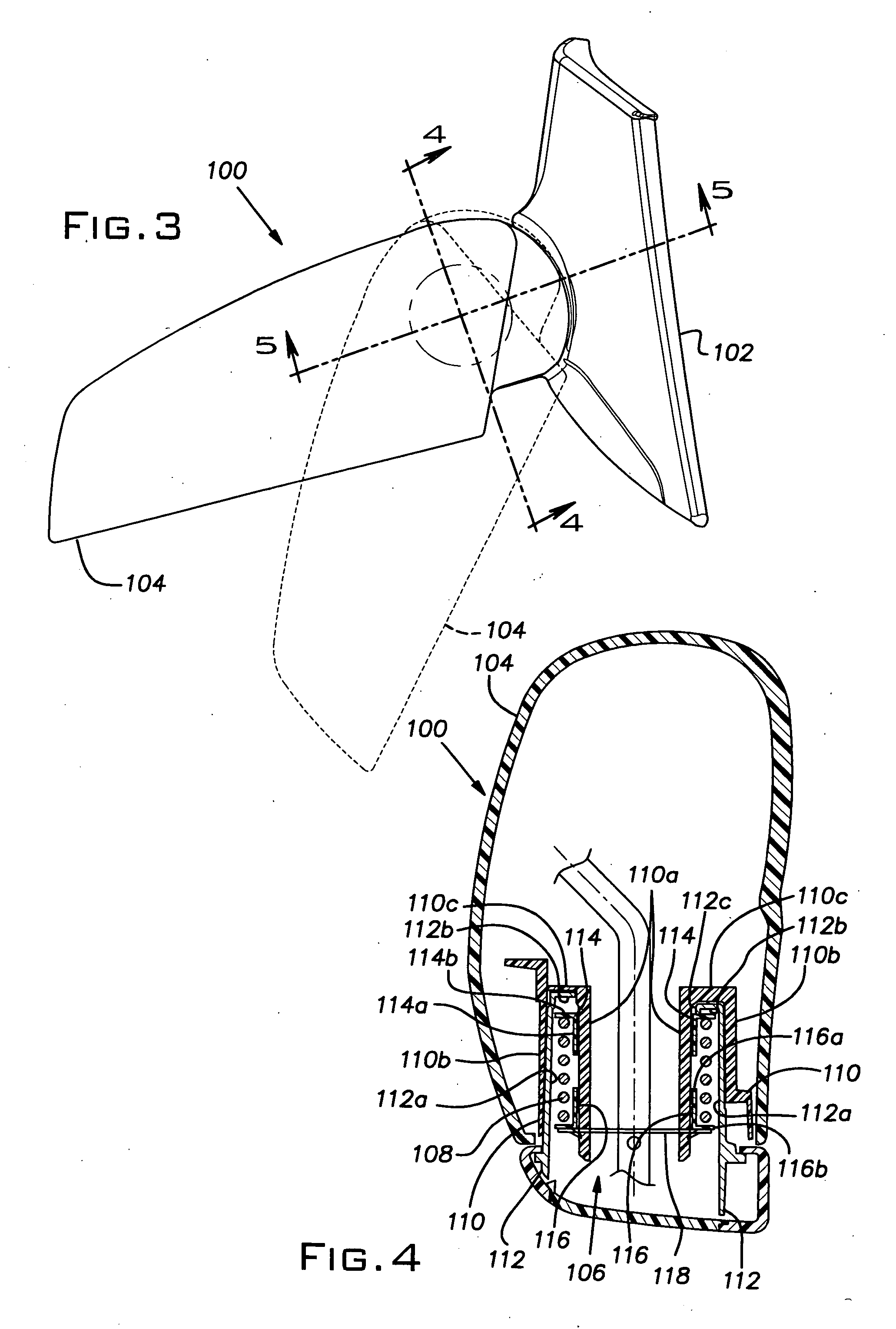

[0023] With reference to FIGS. 1-3, a folding automobile mirror assembly 100 is shown to include an outer base 102 and a mirror housing 104. The mirror housing 104 is pivotally secured to the outer base 102 such that the mirror housing 104 may be manually moved from an outwardly extended or normal position to a folded or storage position. The storage position is illustrated in dashed lines in FIG. 3. Conventionally, the mirror housing 104 will move vertically upward slightly from a normal vertical position to a raised vertical position as the mirror housing 104 pivots from the normal position toward the storage position. The mirror housing hinge assembly includes a spring that biases the mirror housing toward the normal vertical position and away from the raised vertical position so as to provide resistance to the pivoting movement. The folding automobile side mirror assembly disclosed to this point is conventional in appearance and function, and will be described hereinafter as it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com