Cushioning laminate insert for a garment shoulder strap, and method for making the same

a technology of laminate inserts and garments, which is applied in the direction of garments, garment suspenders, garments, etc., can solve the problems of indentation or irritation of the shoulder skin, the strap on and the pad has proved to be bulky and unsightly, so as to reduce the discomfort and depression of the shoulder of the wearer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

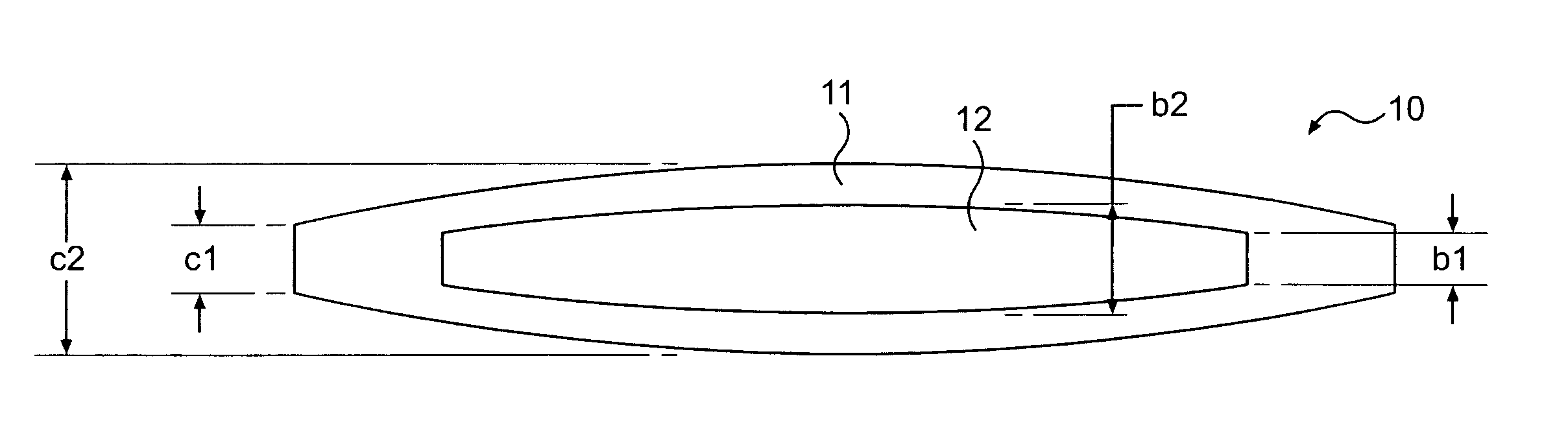

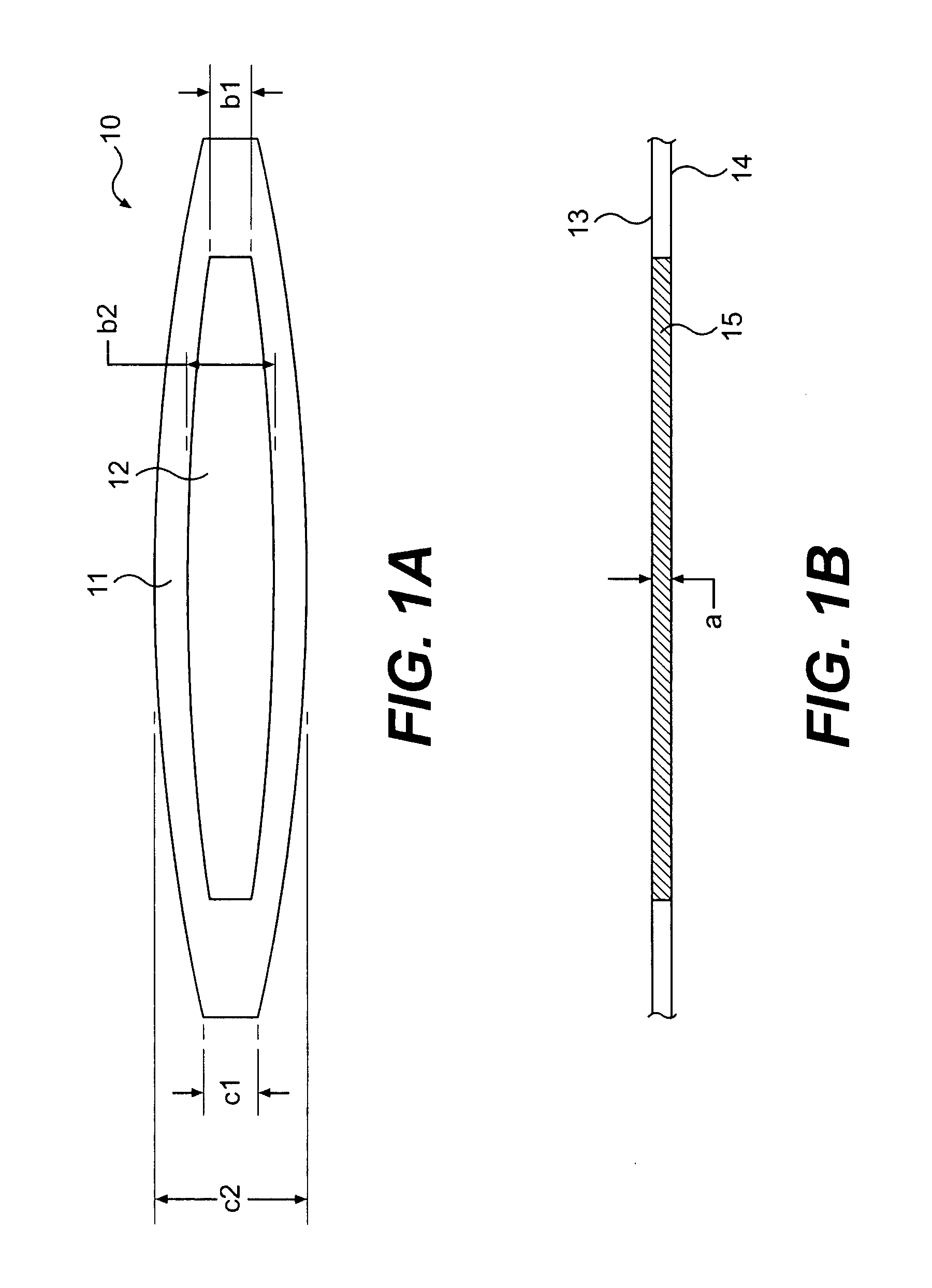

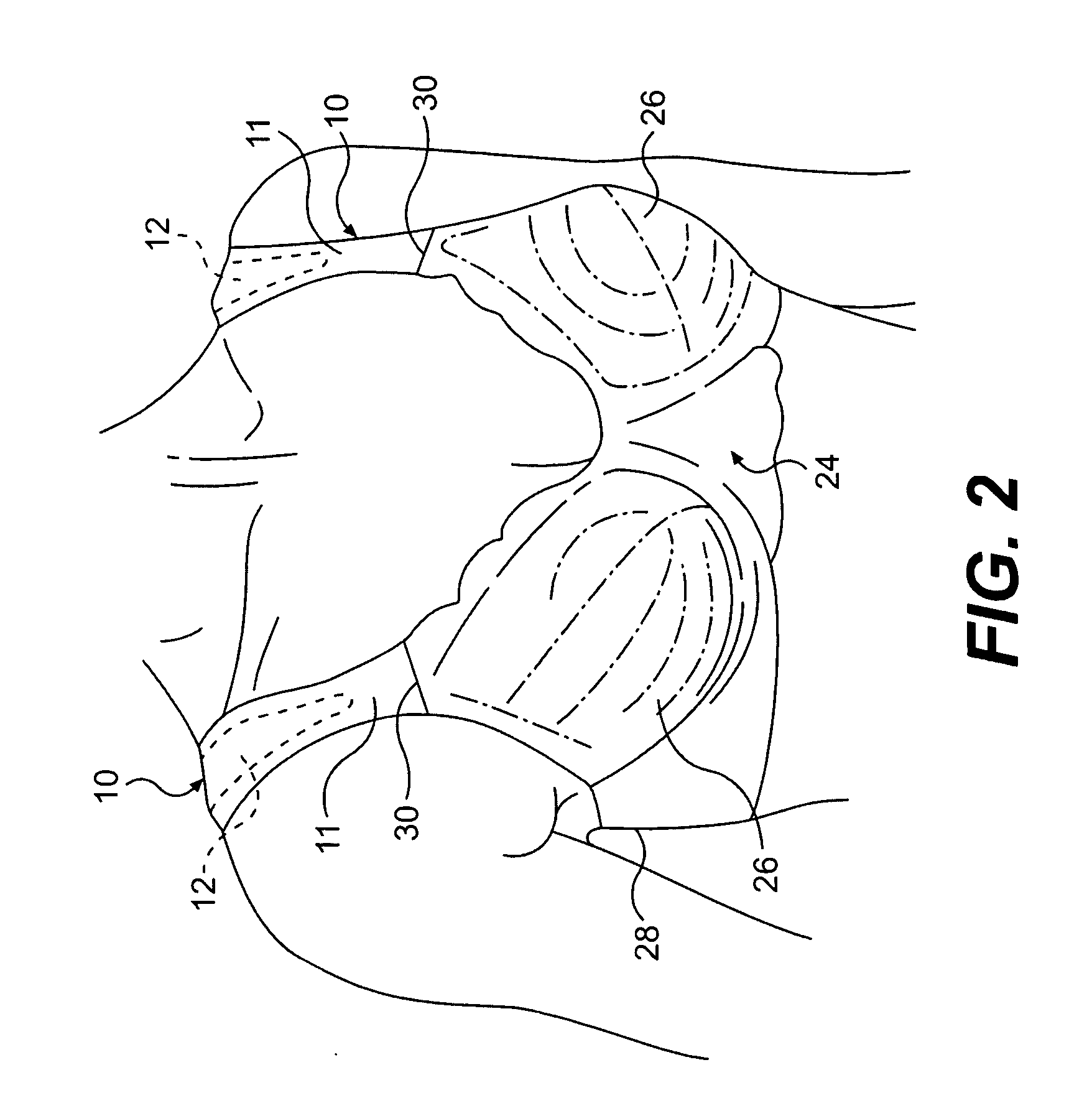

[0015] Referring to FIGS. 1A and 1B, in one aspect, the cushioning laminate insert 10 of the invention comprises outer periphery edges 11 and a central cushioning area 12. In a preferred embodiment, the insert 10 is configured as a laminate, open sandwich-type construction (shown in FIG. 1B). A first outer fabric layer 13 and a second outer fabric layer 14 are adjacent opposite lateral surfaces of the central cushioning area 12 which comprises a cured polyurethane elastomer 15. One surface of the first and second outer fabric layers 13, 14 is laminated with a thermoplastic urethane (“TPU”) film. The TPU film of the first outer fabric layer 13 is covalently bonded to a lateral surface of the cured polyurethane elastomer 15 of the central cushioning area 12. The opposite lateral surface of the cured polyurethane elastomer 15 of the central cushioning area 12 is self-adhered to the TPU film of the second outer fabric layer 14. In a preferred embodiment, the second outer fabric layer 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com