Propulsion system for a watercraft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

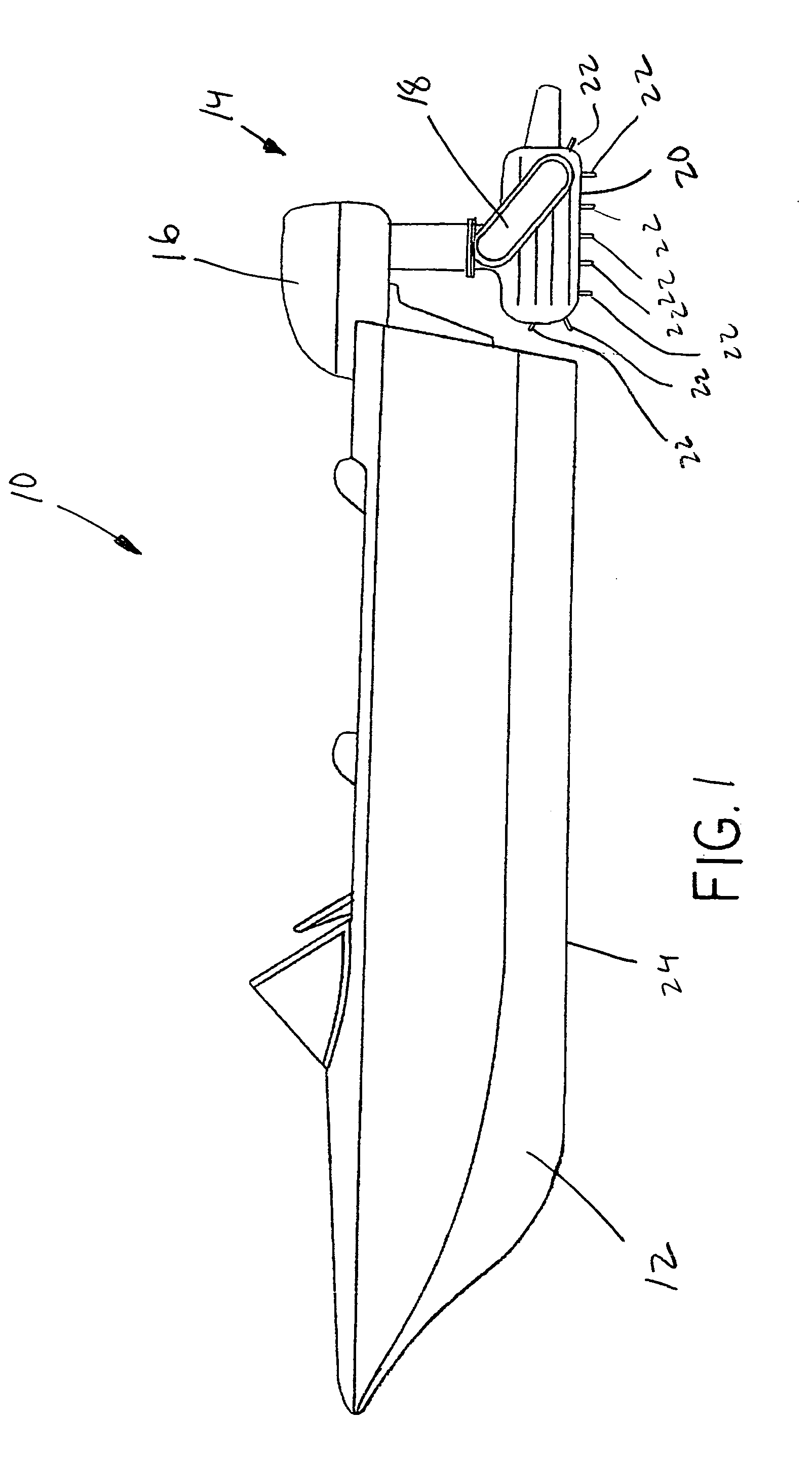

[0031] Referring now to the drawings, and more particularly to FIG. 1, there is shown a watercraft 10 which generally includes a hull 12 and a propulsion system 14 connected to hull 12. Propulsion system 14 includes a motor 16, a drive 18 connected to motor 16 and at least one belt 20 carried by drive 18.

[0032] Motor 16 is shown as an outboard motor but can alternatively be an inboard motor. Drive 18 can be at least one of a direct drive, a hydraulic drive, an electrical drive and a mechanical drive. Drive 18 is shown as an outboard drive but can alternatively be an inboard drive or at least partially inboard. Steering of watercraft 10 can be accomplished by rotating drive 18 (and typically also motor 16 since the two are rigidly connected in an outboard configuration) about a pivot axis.

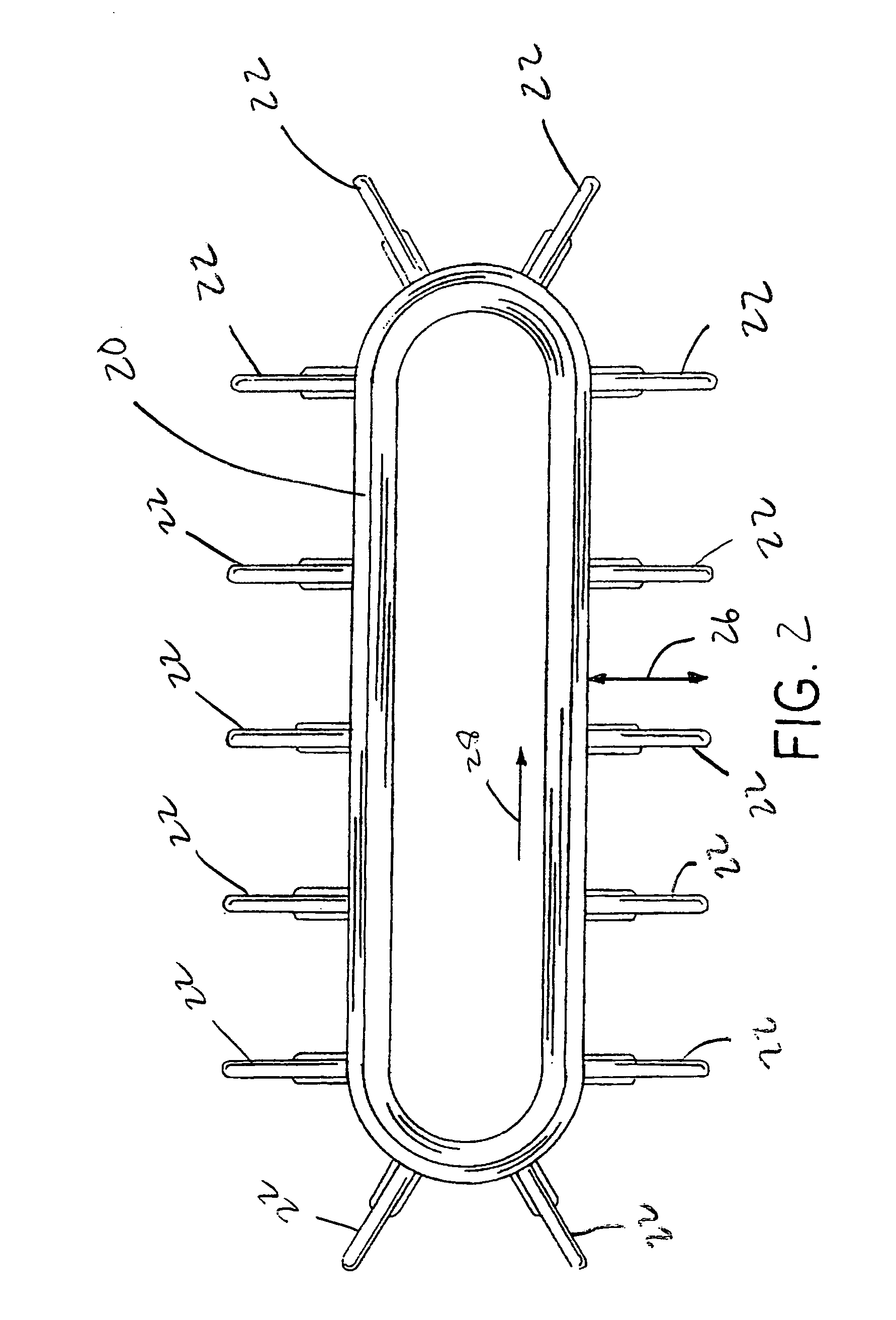

[0033] Belt 20 includes at least one paddle 22 extending outwardly from belt 20. Belt 20 can be made of rubber, urethane, other elastomers, metals including steel and stainless steel, other flexib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com