Electronic part transport device and inspection apparatus using the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

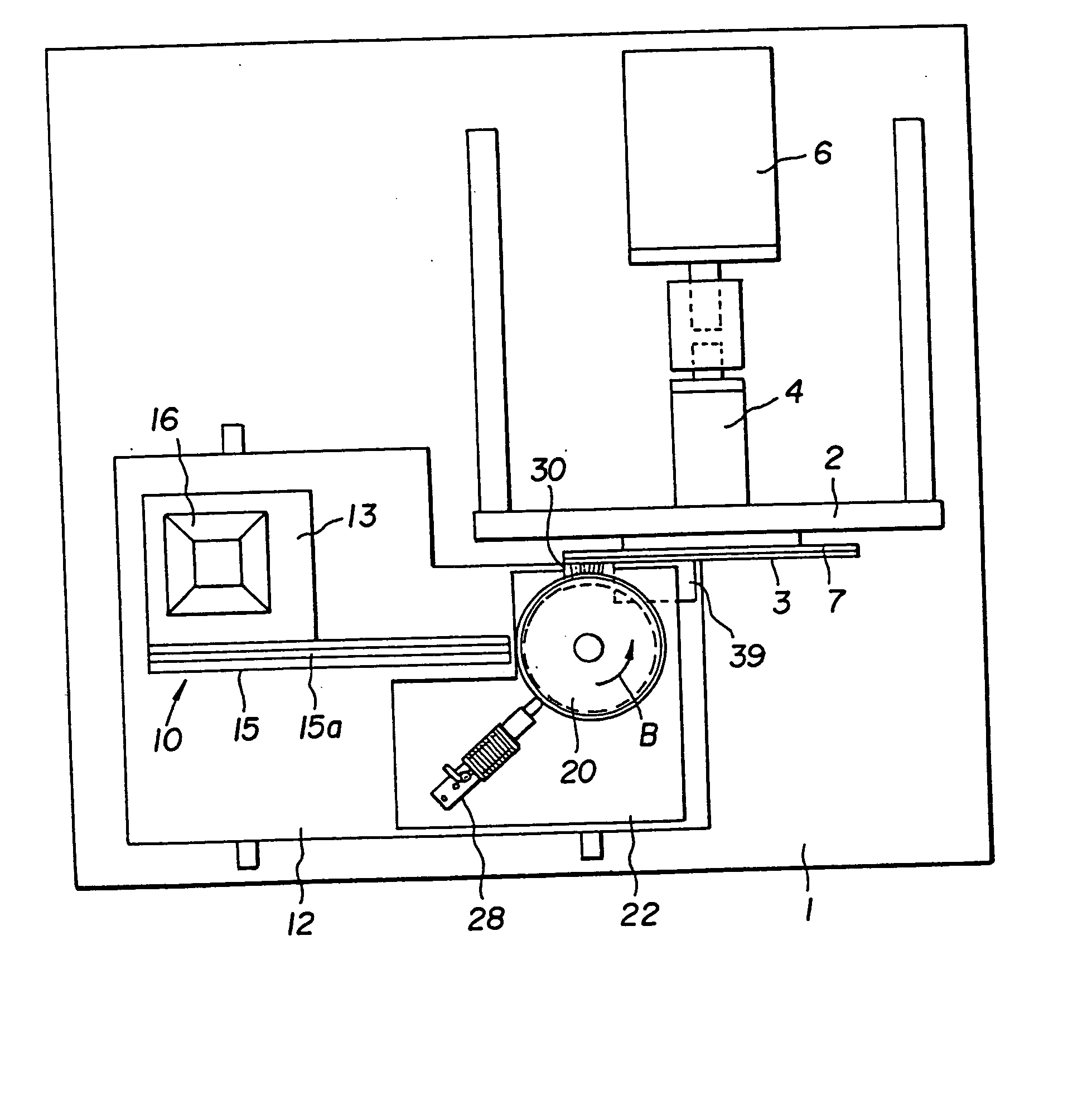

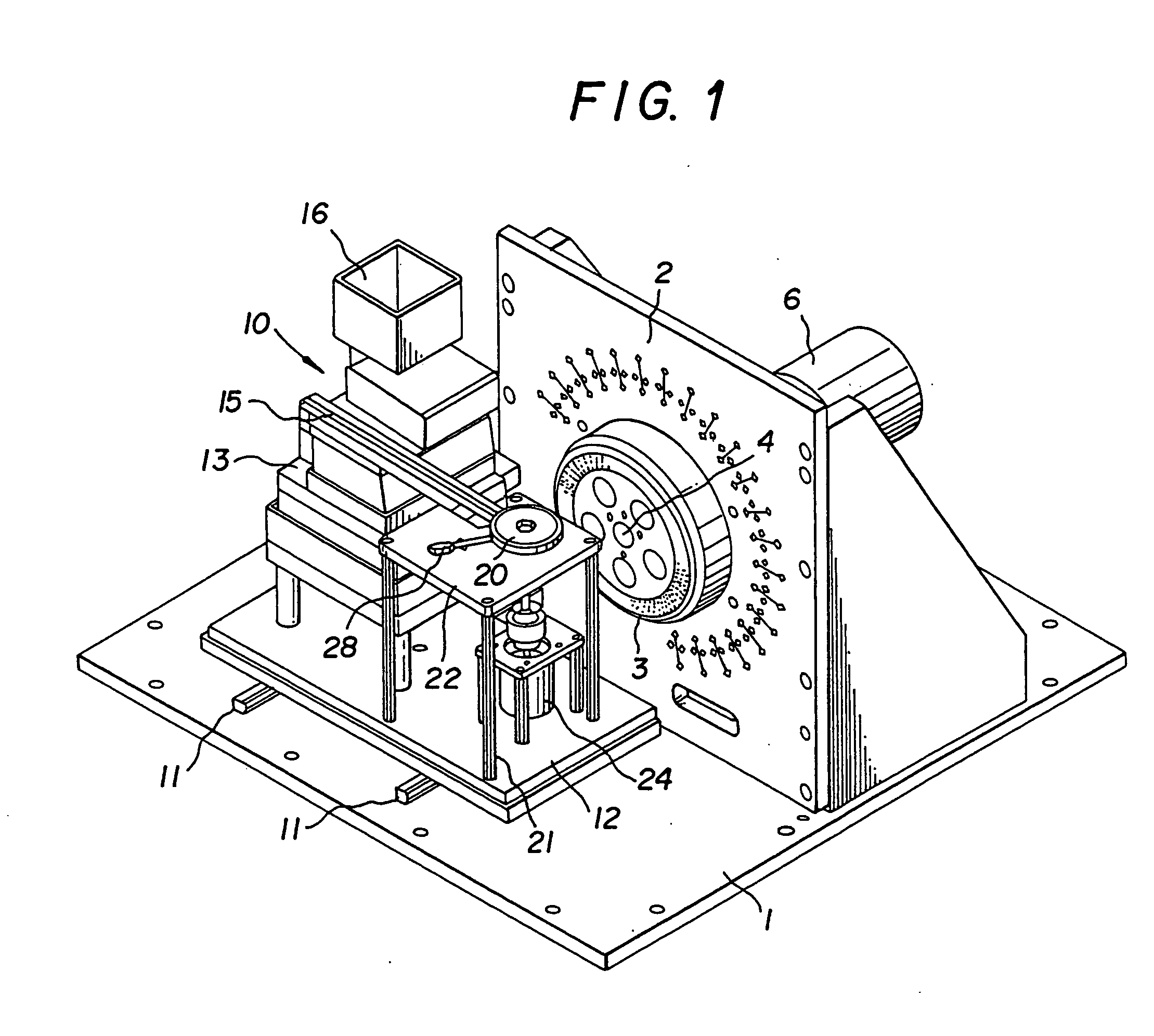

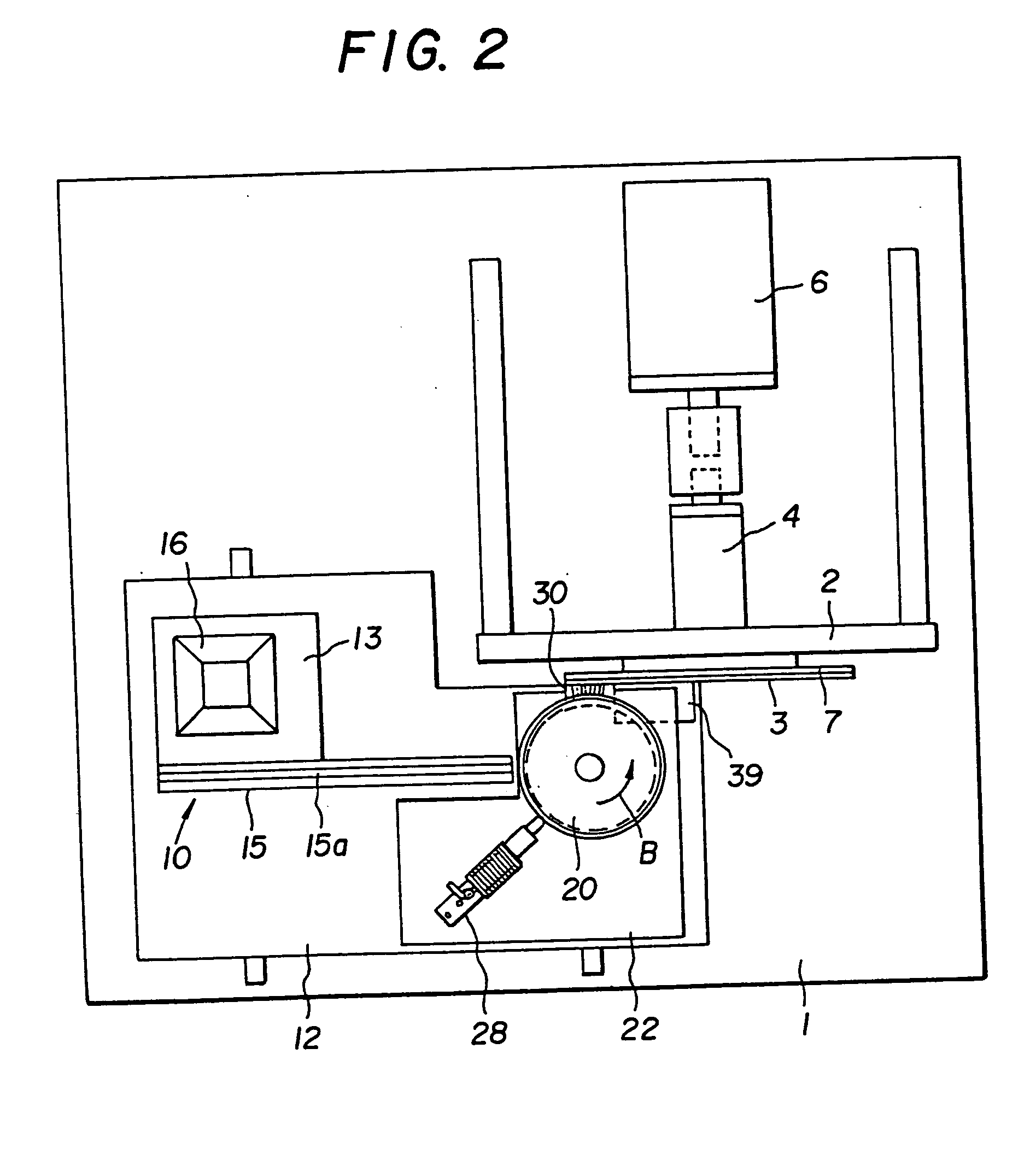

[0047] FIGS. 1 to 8 show an embodiment in which a transport device of the present invention is applied to an inspection apparatus.

[0048] In this embodiment, chip type electronic parts C shaped like a rectangular parallelepiped having a height H, a width W, and a length L (H≈W L>H, and L>W) are used as electronic parts to be inspected, as shown in FIG. 9. Each electronic part C has electrodes Ca and Cb formed at both ends in the longitudinal direction.

[0049] The inspection apparatus comprises a turntable 3 serving as a transport medium, a parts feeder 10 serving as a supply means, a distributing rotor 20 serving as a separating means, and the like, as shown in FIG. 1.

[0050] An upright mounting wall 2 is placed on a base 1 disposed in a fixed section. The turntable 3 is mounted on the mounting wall 2 so as to rotate about a horizontal rotation axis 4. The turntable 3 is made of an insulating material and is integrally shaped like a disk. A plurality of (four in this embodiment) con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com