Water closet flange hub assembly

a technology for flange hubs and water closets, applied in water closets, water installations, construction, etc., can solve the problems of high labor intensity and high cost of replacemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

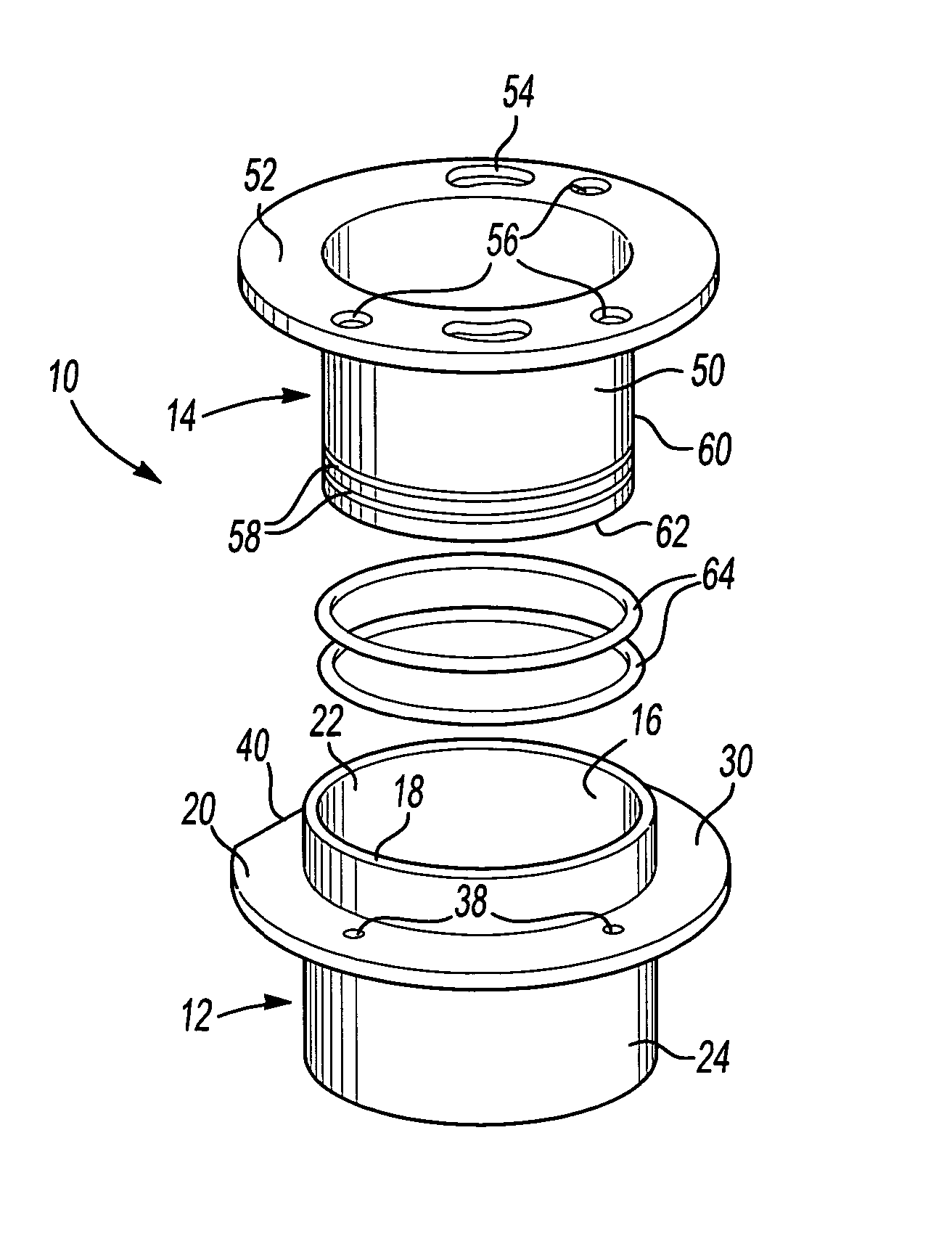

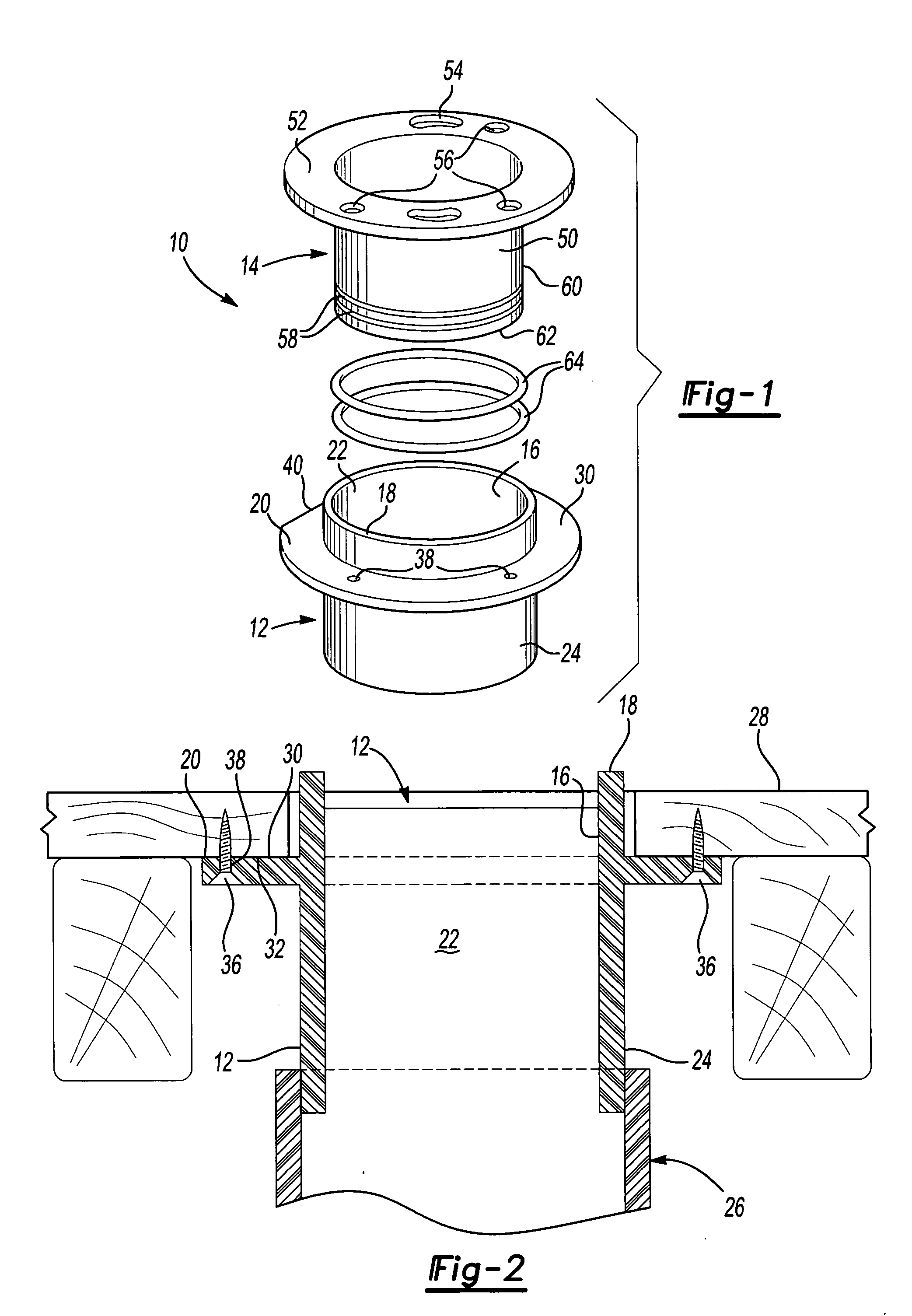

[0017] With reference first to FIG. 1, a preferred embodiment of the water closet flange hub assembly 10 of the present invention is shown. The water closet flange hub assembly 10 includes both an annular base 12 as well as a water closet hub 14. Both the annular base 12 and water closet hub 14 are preferably of a one-piece plastic construction.

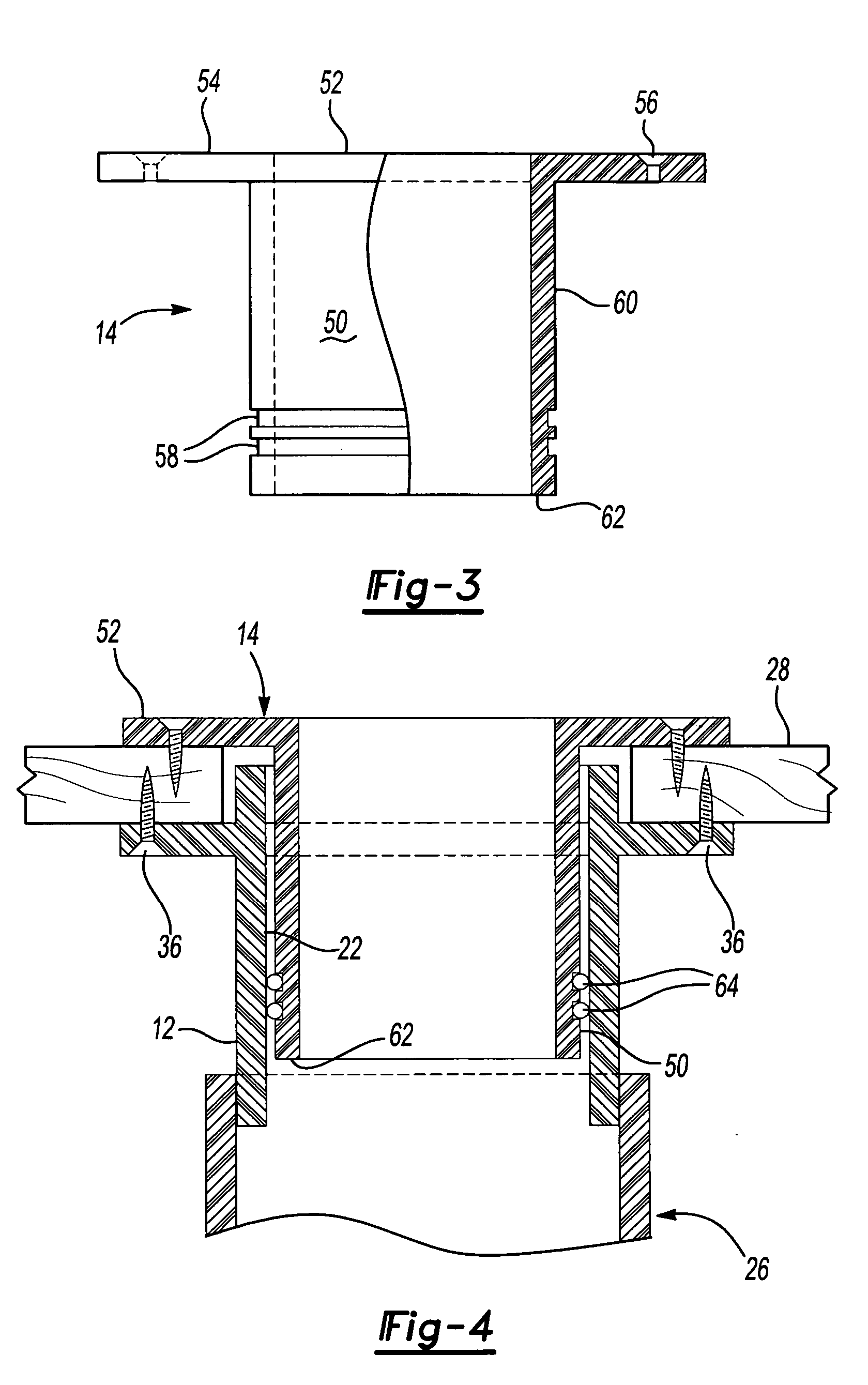

[0018] With reference now particularly to FIG. 2, the annular base 12 is shown in greater detail and includes a central cylindrical throughbore 16. The annular base 12, furthermore, is generally tubular and cylindrical in shape and includes a radially outwardly extending flange 20 at a position spaced downwardly from an upper open end 22 of the base 12. A lower end 24 of the base 12 is fluidly connected to a waste system 26 (only partially illustrated) of a structure. Typically, the waste system 26 is also constructed of plastic and the base 12 is secured to the waste system 26 by chemical welding.

[0019] Still referring to FIG. 2, the hub 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com