Apparatus and method for treating synthetic grass turf

a technology of artificial grass and apparatus, applied in the direction of cleaning equipment, applications, cleaning equipment, etc., can solve the problems of reducing the proper resiliency and shock absorption properties required, weeds growing into artificial grass surfaces are unwanted, and require maintenan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

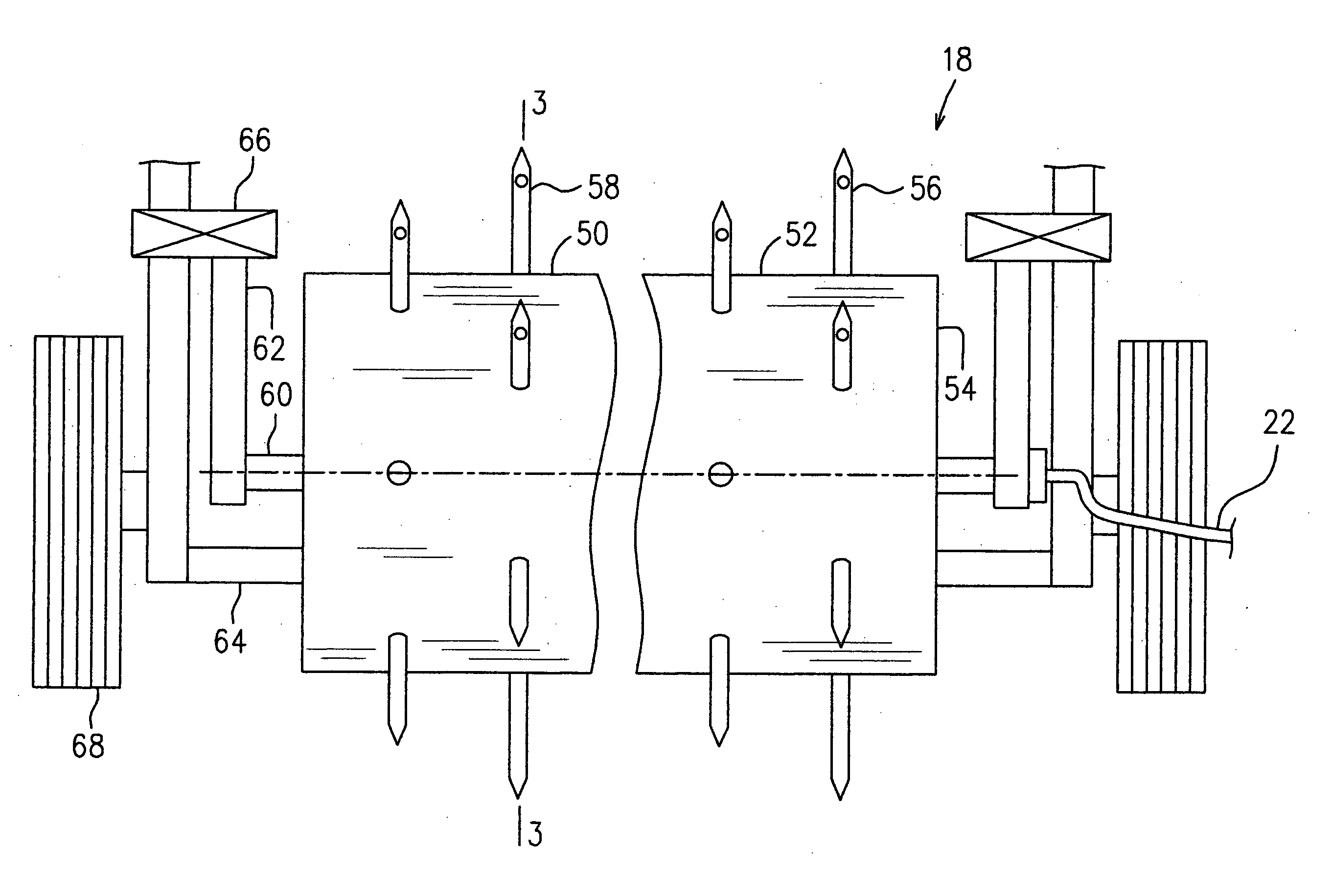

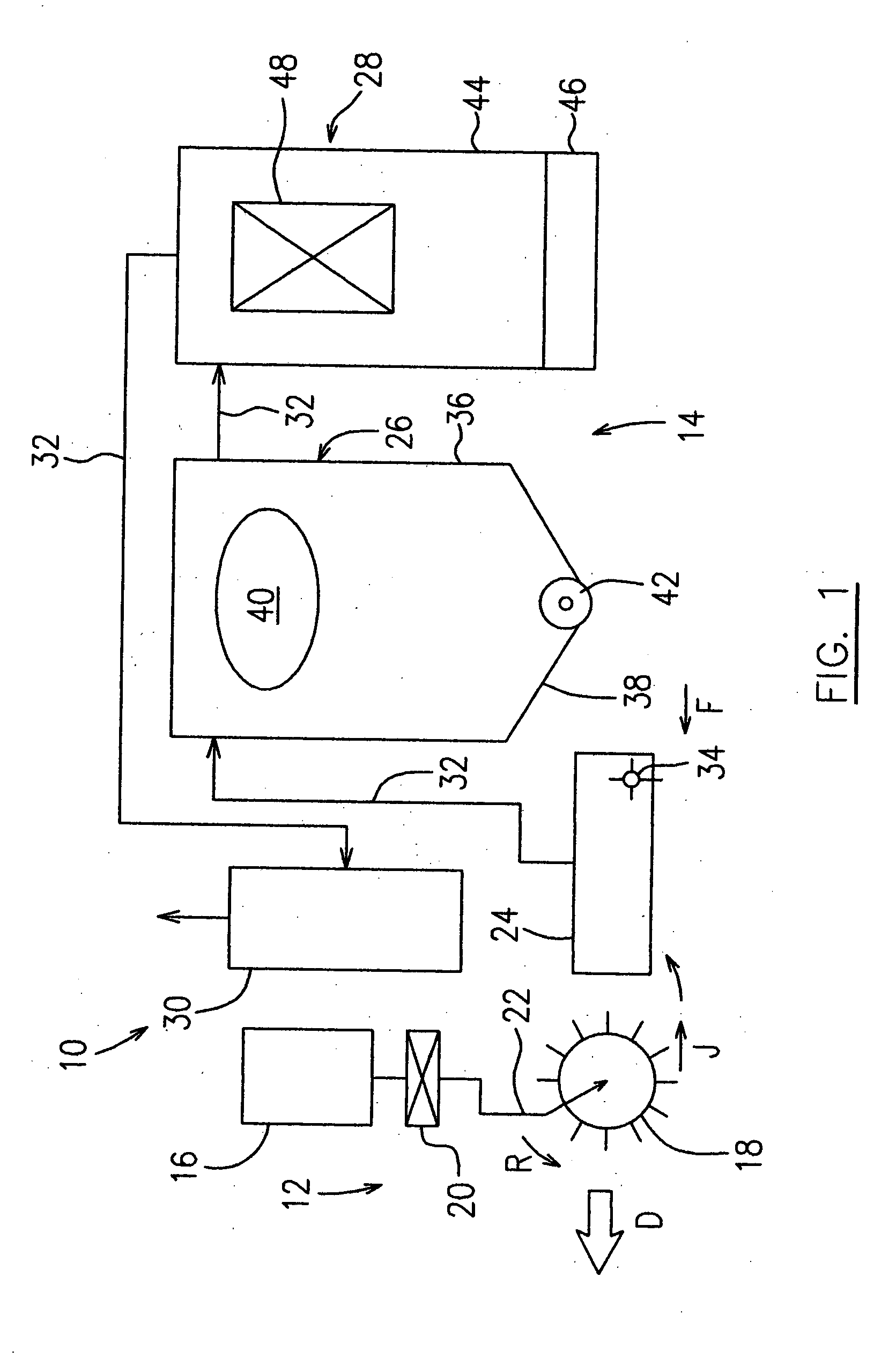

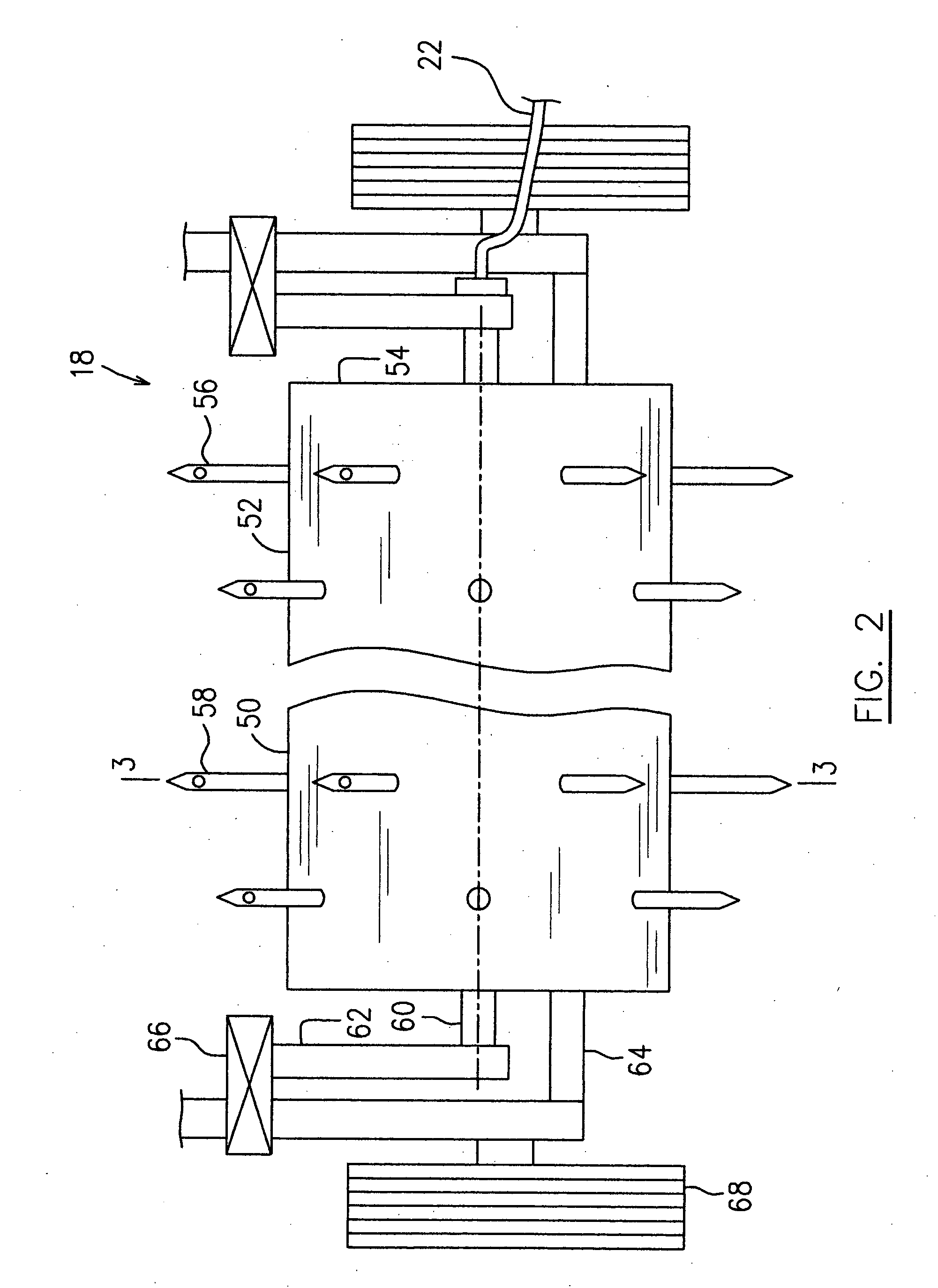

[0028]FIG. 1 is a diagram schematically illustrating a grass turf treatment apparatus which is particularly useful for treating synthetic grass turfs. However, the apparatus can also be used to treat natural grass turfs. According to one preferred embodiment of the present invention, the apparatus which is generally indicated by numeral 10, includes a fluid ejection system 12 and a vacuum system 14.

[0029] The fluid ejection system 12 generally includes a pressurized fluid source 16. In various applications, the pressurized fluid source 16 varies when different types of fluid are required. This embodiment illustrates the use of pressurized air, which is more commonly but not exclusively used in a synthetic grass turf treatment operation, and so the fluid source 16 is preferably an air compressor. The fluid ejection system 12 employs a hollow spike roller assembly 18 to direct the pressurized air in a desired direction to a depth of a synthetic grass turf to be treated. This means th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com