Pump system for conveying lubricating oil

a pump system and lubricating oil technology, applied in the field of pump systems, can solve the problems of high stress on the pivoting connection of the chain link, the inability to adjust the pump system, so as to reduce the maximum capacity, prevent the effect of incorrect adjustment and small mechanical effor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

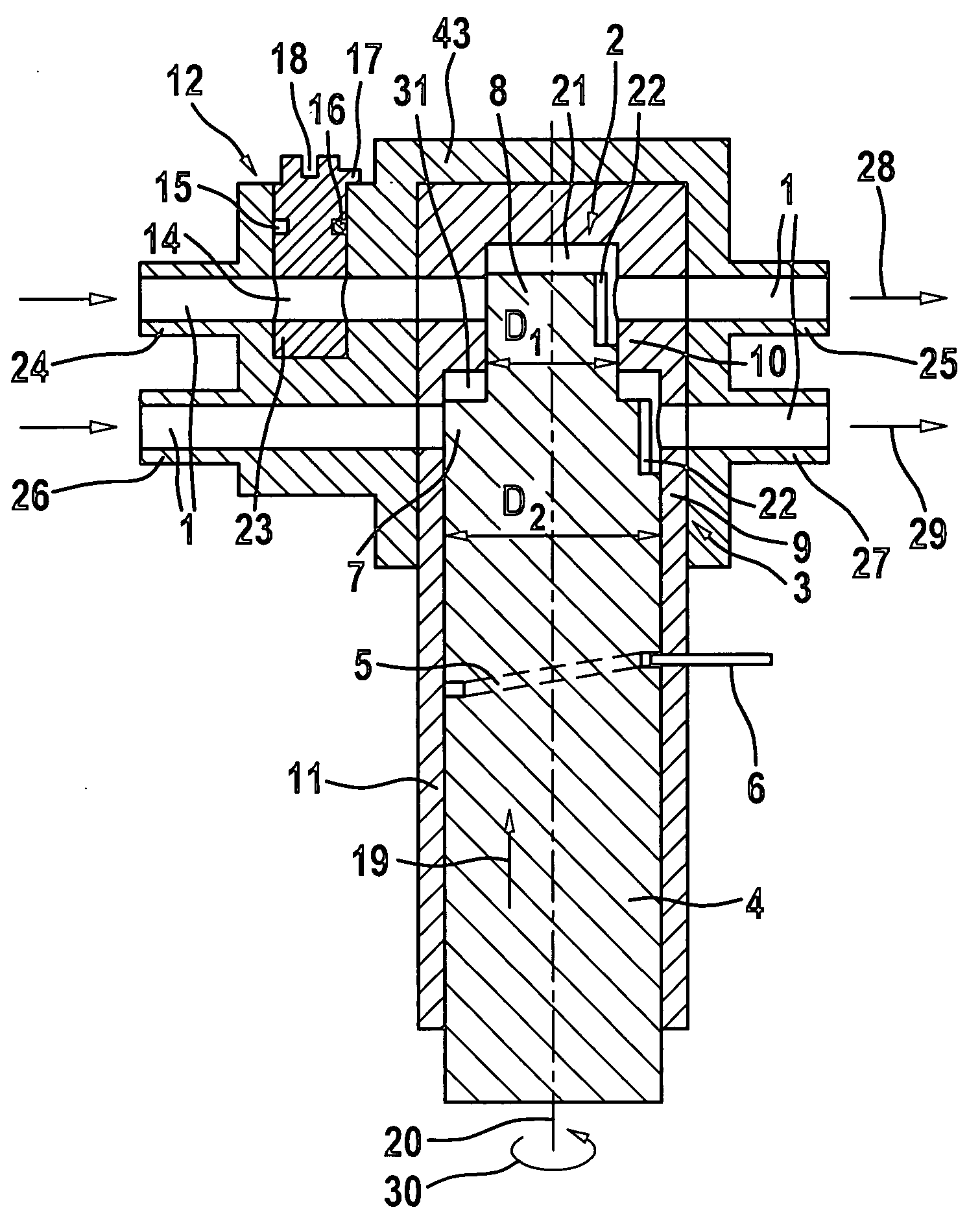

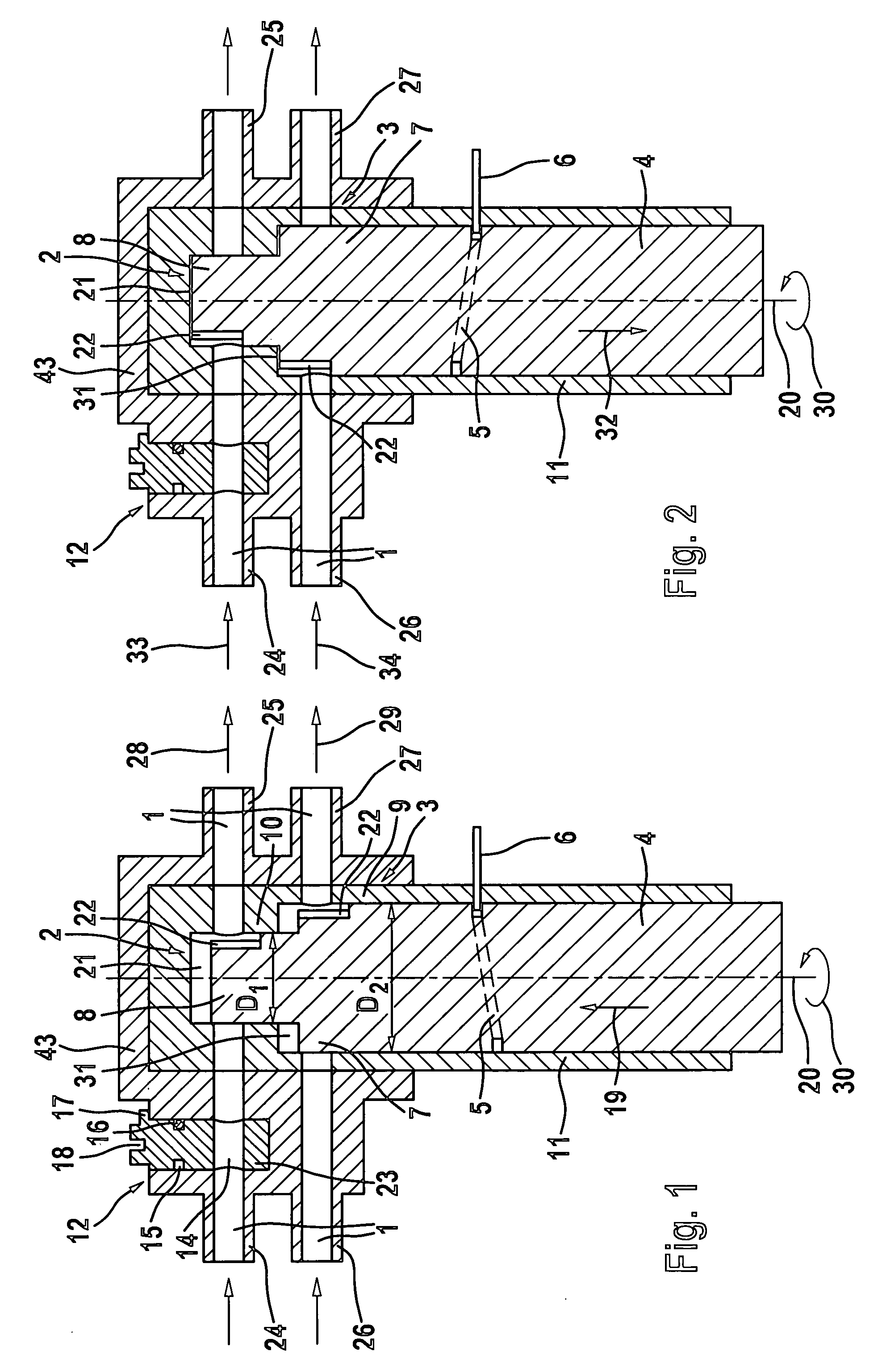

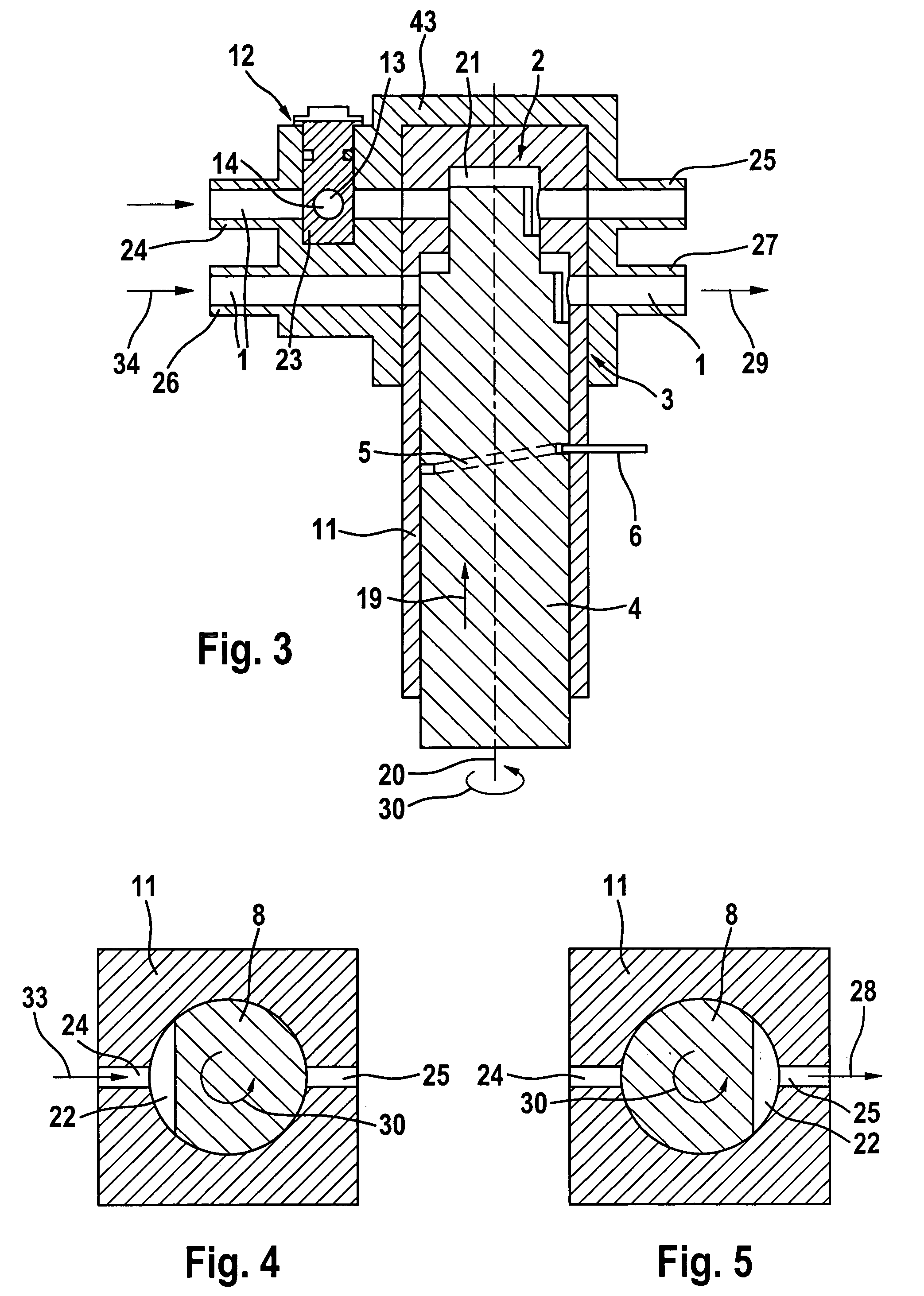

[0024] Referring now to the drawings in detail, FIG. 1, in a cross-sectional illustration, shows a pump system for conveying lubricant or lubricating oil 1 to a cutting chain of a non-illustrated chain saw. The pump system includes an oil pump 2, which can be adjusted by a user, as well as a basic oil pump 3. The two oil pumps 2, 3 each have a supply or feed conduit 24, 26, as well as a discharge conduit 25, 27. The lubricating oil 1 is drawn in via the feed conduits 24, 26, and is discharged via the discharge conduits 25, 27. The adjustable oil pump 2, and the basic oil pump 3, are connected via their pertaining feed conduits 24, 26 with the same, non-illustrated oil tank. The two discharge conduits 25, 27 lead to the cutting chain of the chain saw, which results in a parallel connection of the two oil pumps 2,3. Further adjustable oil pumps 2, for achieving a plurality of operating stages, can also be connected in parallel.

[0025] The pump system can be configured as a system havi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com