Device for traversing a flexible linear product for spooling

a technology of flexible linear products and spooling, which is applied in the direction of transportation and packaging, thin material processing, filament handling, etc., can solve the problems of reducing the life of said components, slowing down the spooling process, and previous devices not performing the direction reversal of pivotally mounted guides

Inactive Publication Date: 2004-02-05

KLAUS DAN

View PDF4 Cites 24 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

These mechanical linkages add considerable inertia to the device, thereby slowing the spooling process.

In addition, these compensating components are of high frictional wear that reduces the life of said components.

Previous devices have not performed direction reversal of the pivotally mounted guide, other than end of stroke mechanical linkage adjustments.

Where the guide is driven at high speeds, the heavy inertial load of the mechanisms impedes any instant reversal of the path of movement.

Previous traversing components, for the most part, have not addressed the tension fluctuations and product abuse that are common to traversing.

Any deviation or bending of the filament from its relaxed alignment is detrimental.

This may seem to be a minor variation, but in high speed traversing, the tension fluctuations produced by this deviant path are detrimental.

An additional difficulty with the disclosed device is the multiple radial bends that are employed to route the cable to its final destination.

Thus this device was clearly not designed for high-speed delicate winding, as can be easily seen by the mass of the structure.

This traversing mechanism winds a predetermined path and lacks the capabilities to change lay or traverse width other than mechanical retooling.

Any change or wear in the cam box or linkages will produce erroneous guide position feedback.

The eventual wear of both the cam box and the slide block are not desirable Another detrimental quality of the sliding block traverse is the filament misalignment while winding.

In any lateral traversing mechanism the filament is exposed to angular displacement that accumulates product, causing fluctuations in tension.

This introduces additional undesirable radial bends to the filament.

These devices exhibit various difficulties that are detrimental to the high speed processing of delicate products.

As more components are added to the device to compensate for non-uniform motion, the inertial load is increased, hindering the speed or directional changes of the guide.

If stroke adjustments are desired, the linkage must be adjusted or changed or the rotation of the driving member reverse& The surface-to-surface frictional wear of both the slides and cam devices add to the problematic characteristics.

Speed following devices are prone to accumulating error.

The final drawback that is inherent to these devices is one of product misalignment.

This deflection causes two problems.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example

[0071] Let:

Cs=640

Cp=480

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

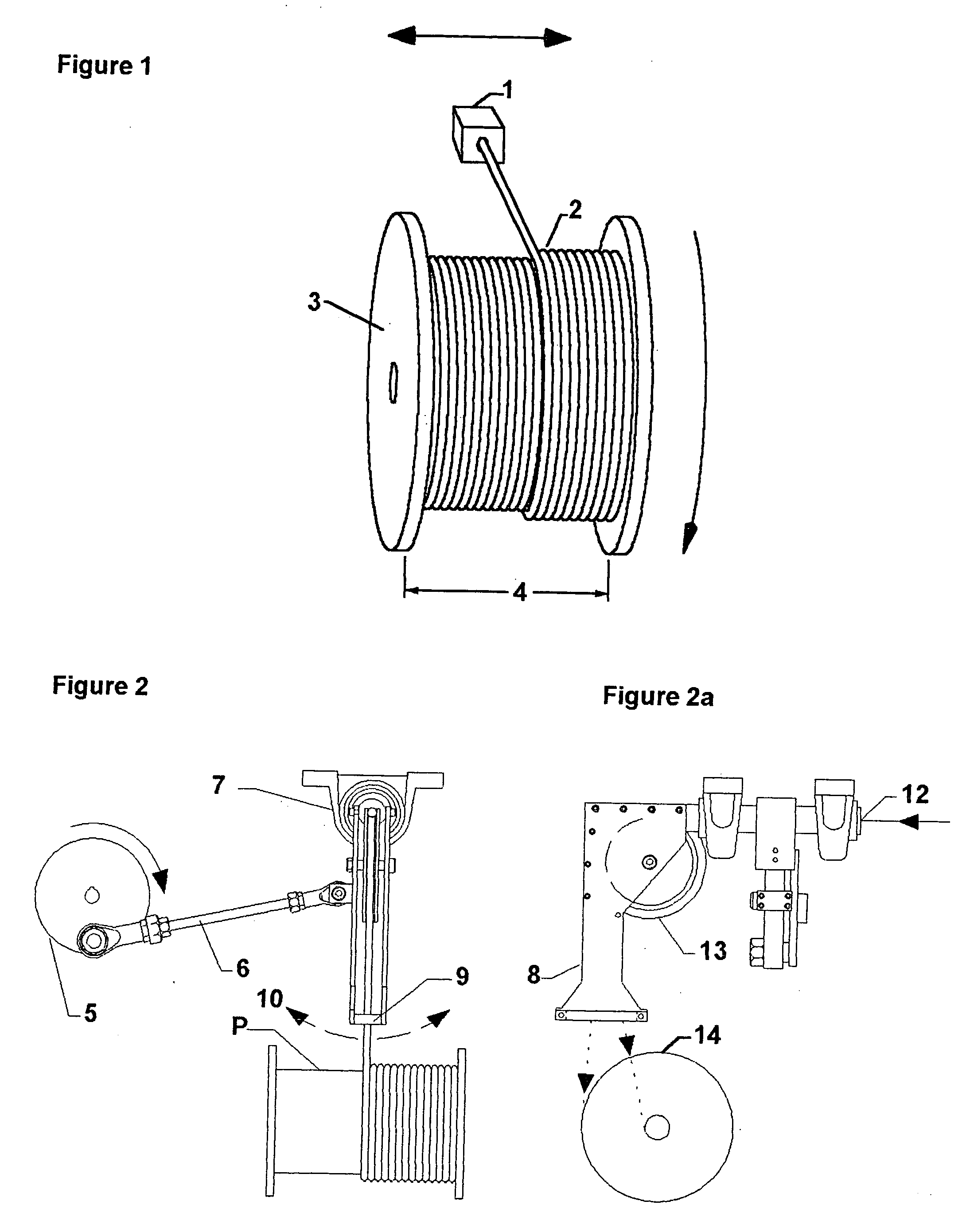

A linear traverse mechanism for guiding the spooling of a flexible linear product at high speed, made possible by reducing the inertial load of the mechanism while reducing the angular deflection of the filament. The mechanism includes a pivotally mounted traverse arm controlled by an electric motor having precision indexing ratio characteristics to compensate for linear error. In one embodiment, the linear product is fed through a guiding means carried by said traverse arm to be discharged adjacent a receiving spool. Control of movement of the traverse arm depends upon manually controlled programming means, which compares a desired position of the traverse arm with an actually attained position of the arm.

Description

RELATED APPLICATON[0001] This application is a continuation-in-part of my co pending application; Ser. No. 09 / 342,826 filed Apr. 27, 2001, which is a continuation in part of application Ser. No. 09 / 427,443 filed Oct. 27, 1999, now abandoned.[0002] This invention relates generally to the field of spooling a delicate flexible linear product such as thread, wire, cable, hose, and the like. It also relates an improved guiding means, which moves in a plane parallel to that of the spool / coil, which forms progressive layers of product as the spool / coil rotates, while minimizing the stresses and tension fluctuations that are created by product misalignment and radial bends.[0003] The invention also relates to the process by which the traversing guide is synchronized with the winding member to form the desired level wind package.[0004] These objectives are accomplished by employing a pivotally mounted guide with the capabilities of digitally addressing the desired position of the guide by ca...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(United States)

IPC IPC(8): B65H54/28

CPCB65H54/2827B65H54/2884B65H54/2848

Inventor KLAUS, DAN

Owner KLAUS DAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com