Operating handle for cleaning device

a technology for operating handles and cleaning devices, which is applied in the direction of cleaning equipment, manufacturing tools, carpet cleaners, etc., can solve the problems of complex manufacturing and consequently high cost, and the known operating handles lack stability at the points of connection of individual handle elements, and achieves simple and inexpensive production. , the effect of high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

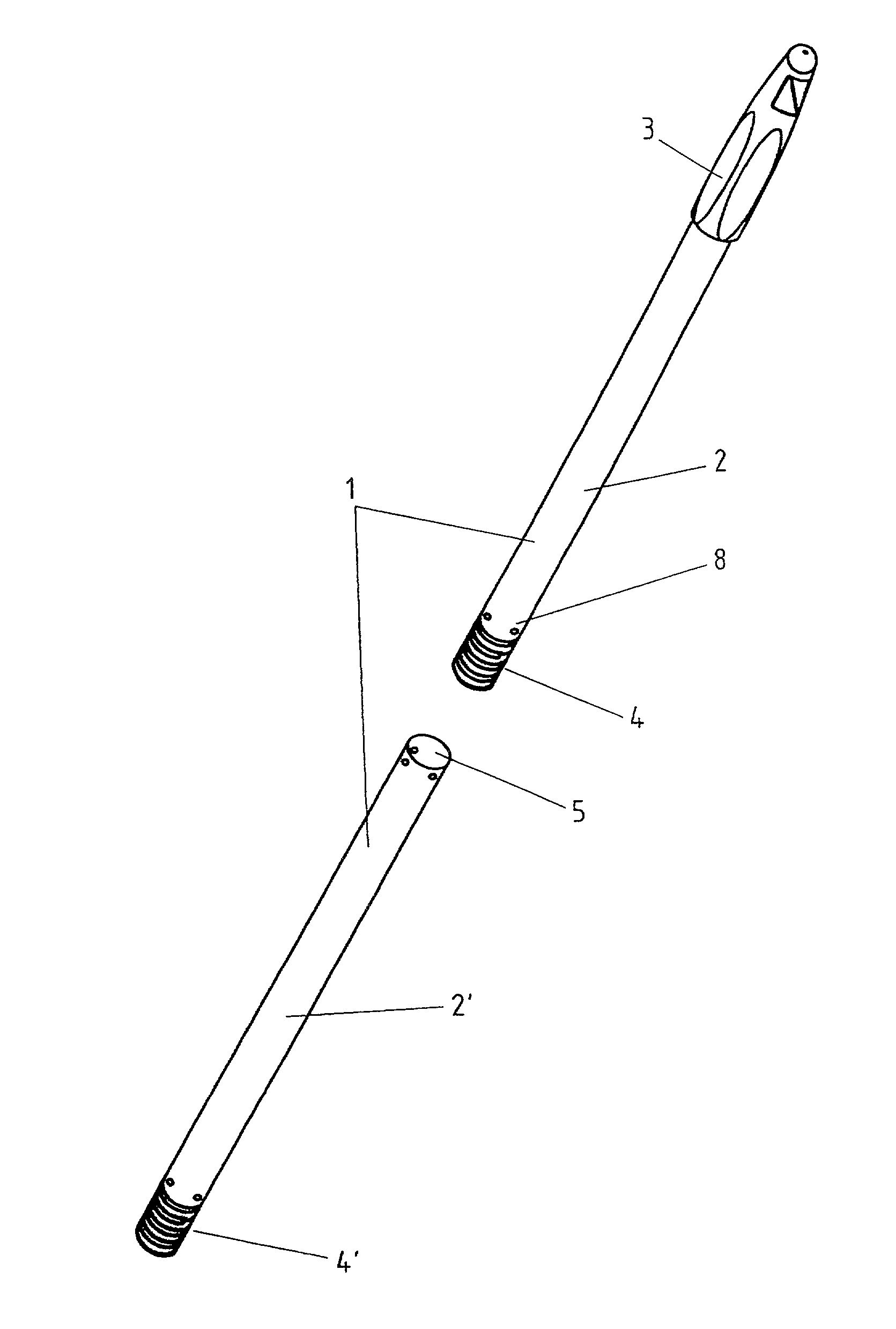

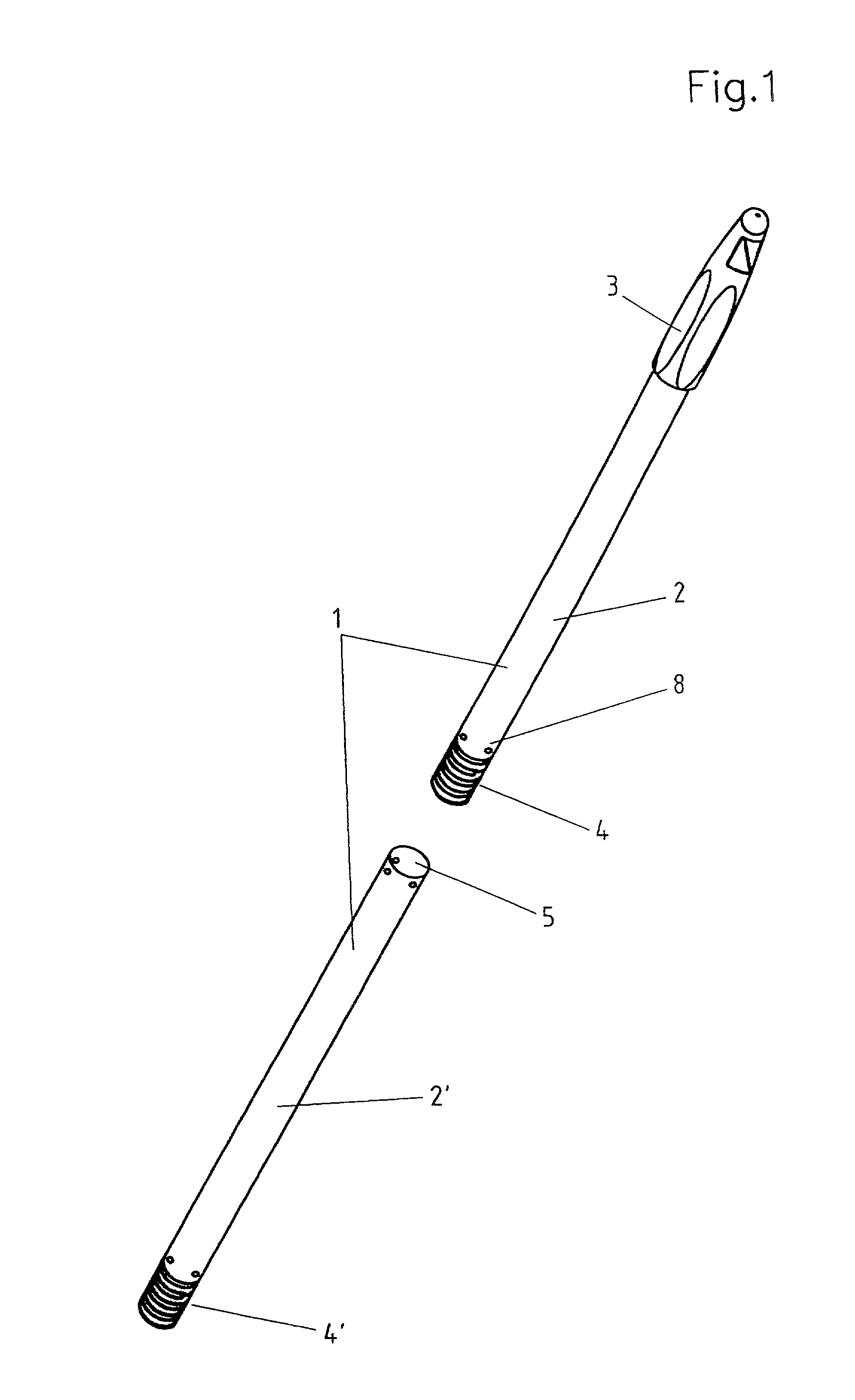

[0017] FIG. 1 shows an operating handle 1 for devices. In particular, the operating handle can be used for wiping devices, mops, brooms, or the like. In this context, the operating handle 1 has a plurality of tubular handle elements 2, 2' which are able to be joined to one another. At the upper end, the operating handle 1 has a grip 3, which is arranged at one end of the first handle element 2, and which terminates the first handle element 2 in an upward direction. Although not illustrated, identically formed handle elements can be added at the lower end of the second handle element 2'. In this way, it is possible to produce a comparatively long total length of the operating handle 1 using relatively short handle elements 2, 2'. This is particularly advantageous when the operating handle 1 is to be packaged in relatively small packaging.

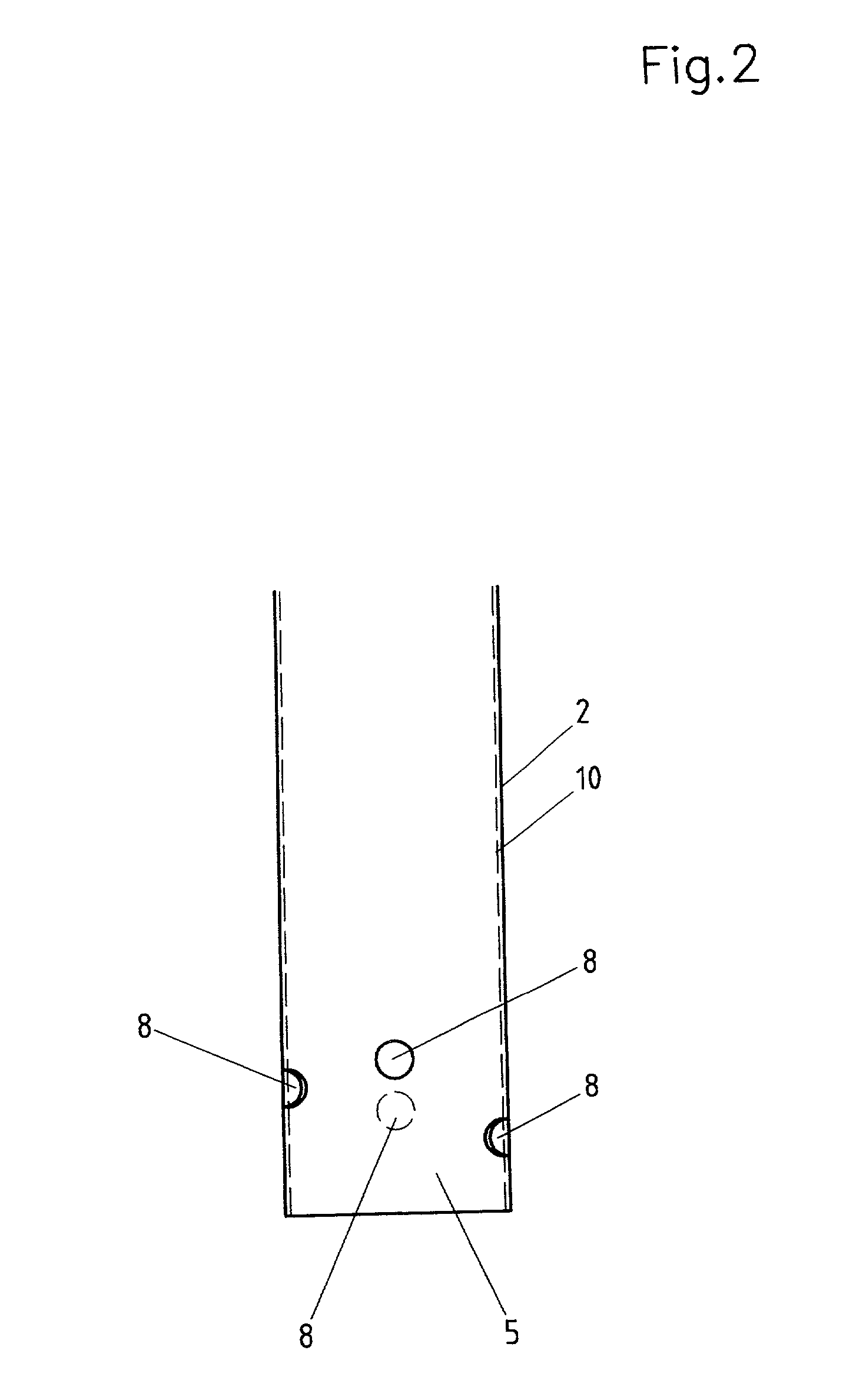

[0018] For connecting the first handle element 2 and the second handle element 2', a first connecting link 4 is provided. A comparable and identical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com