Method and device for stuffing meat product sealed by stapling

a technology of meat products and sealing devices, applied in the direction of butchering, application, linked sausage separation, etc., can solve the problems of not being fully sealed, not having sufficient strength, and obtaining pieces that are unacceptable for obvious sanitary reasons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

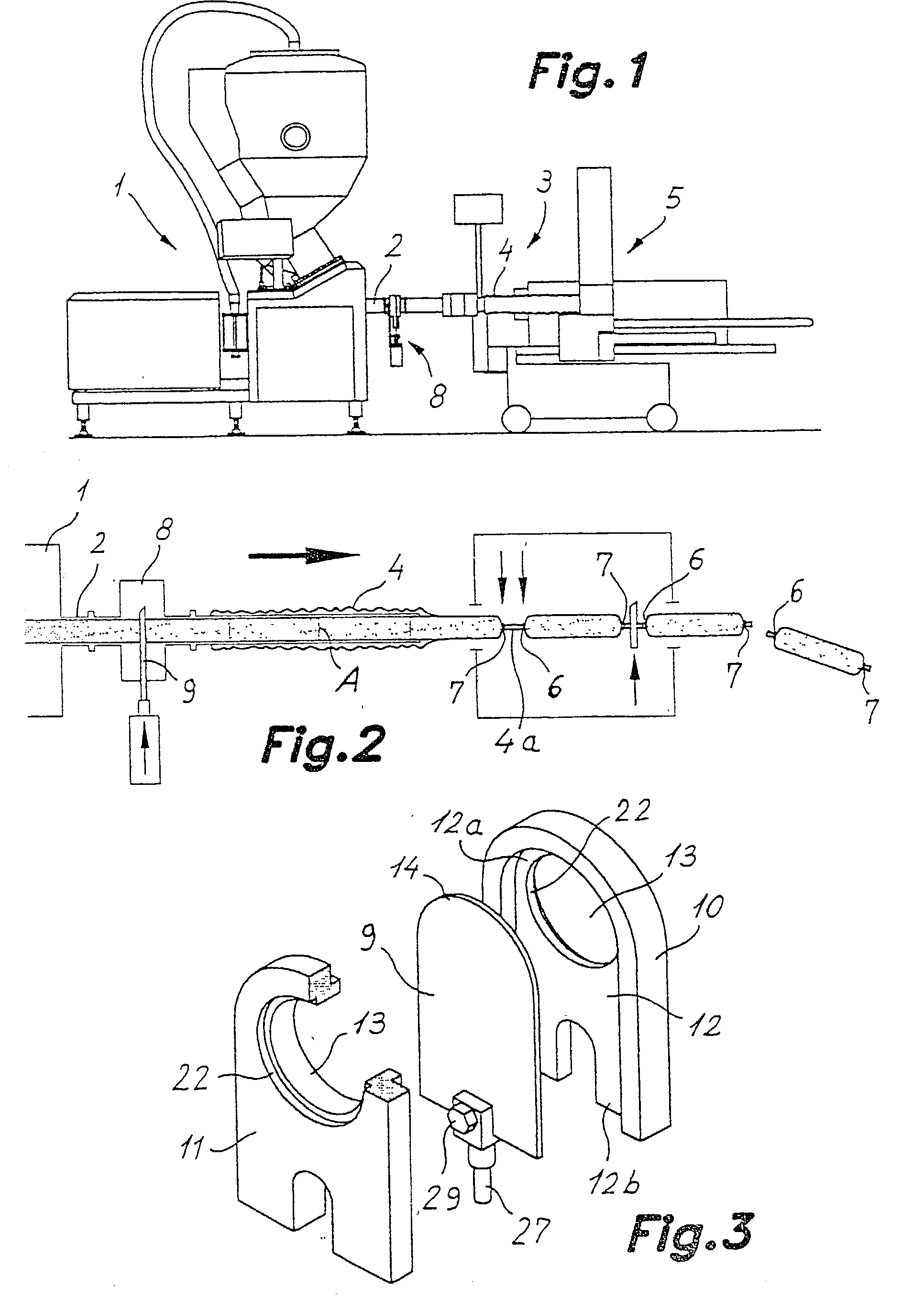

[0007] This invention provides a new method to stuff meat product sealed by a staple which brings a solution to these problems.

[0008] This invention also provides a device to carry out said method.

[0009] The new method essentially consists in introducing a new step in the conventional stuffing process which consists in cutting at regular intervals said continuous flow of meat product before introducing it in said endless sleeve, having said intervals of cutting coincident with the further choking intervals by means of a double staple.

[0010] The cut carried out in the meat continuous flow produces adjacent portions of meat product flow which move jointly within the stuffing duct which push each other. The existence of said cut makes that there is a lack of cohesion between a portion meat product flow and its preceding one which causes at the moment of chocking, that both portions are taken apart for each other, sliding within the sleeve, leaving the portion of sleeve between two adja...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com