Combination workpiece positioning/hold-down and anti-kickback device for a work table

a workpiece and workpiece technology, applied in the field of workpieces, can solve the problems that the application is unaware of any devices, and achieve the effect of preventing kickback

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

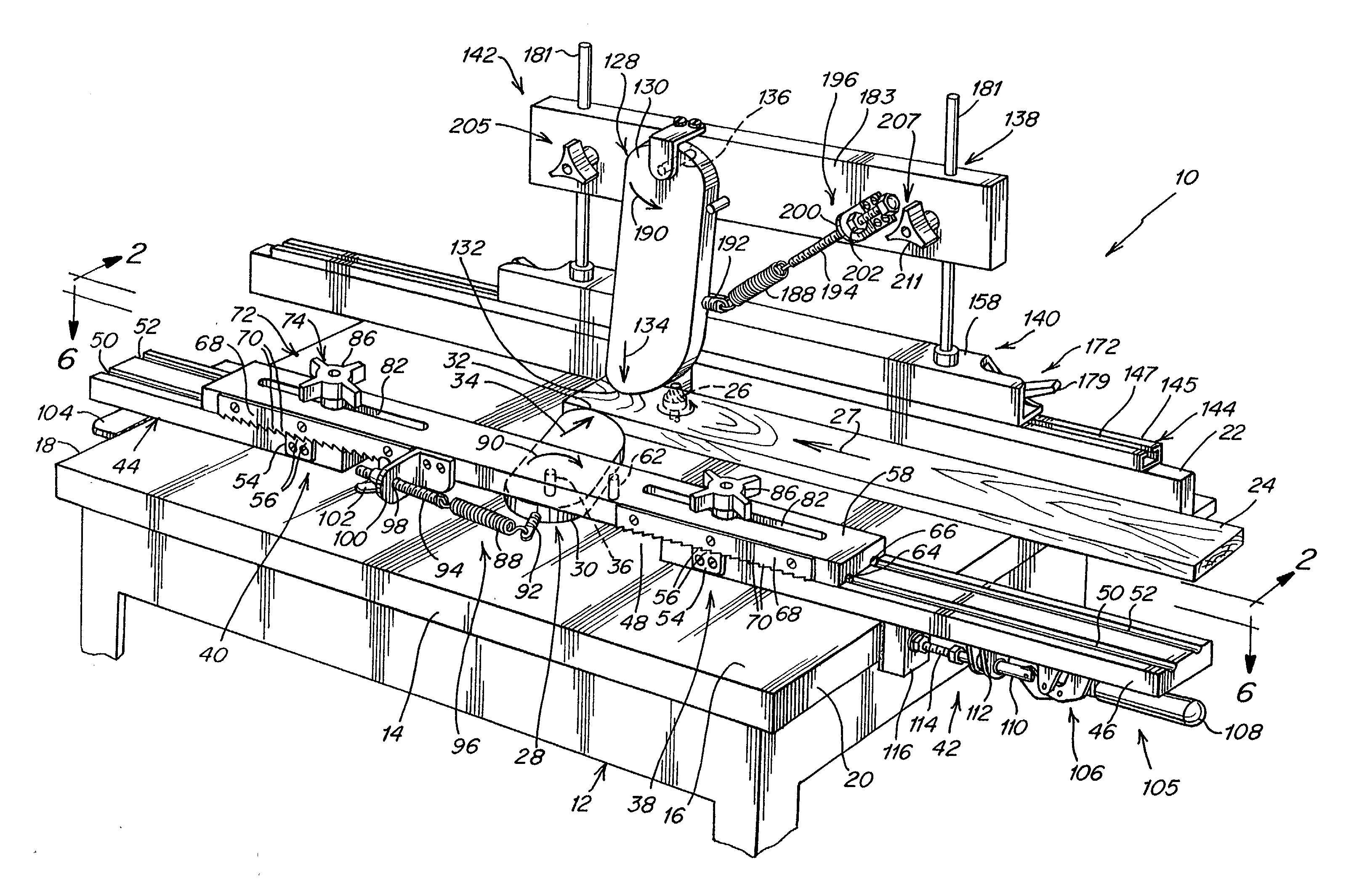

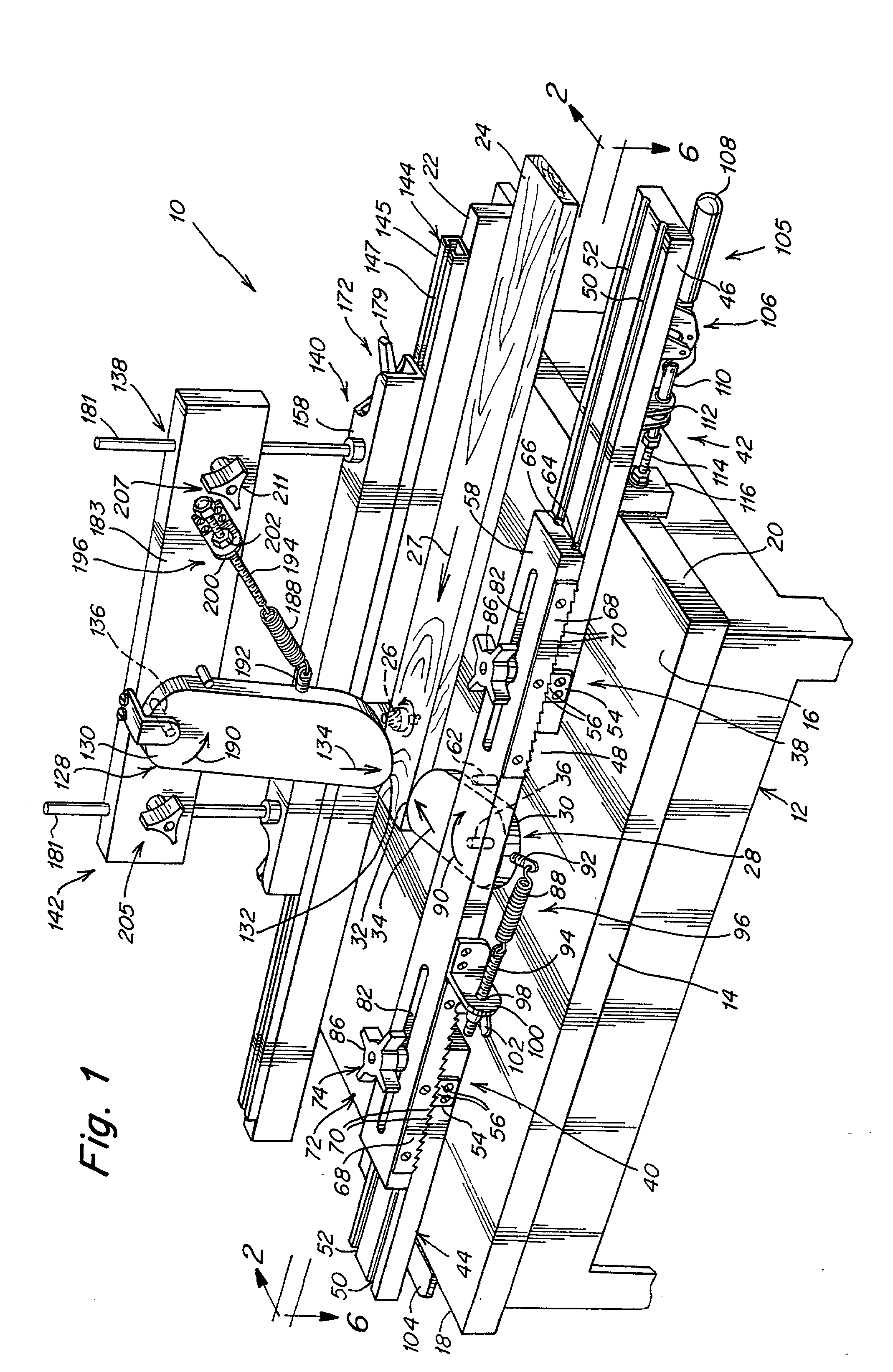

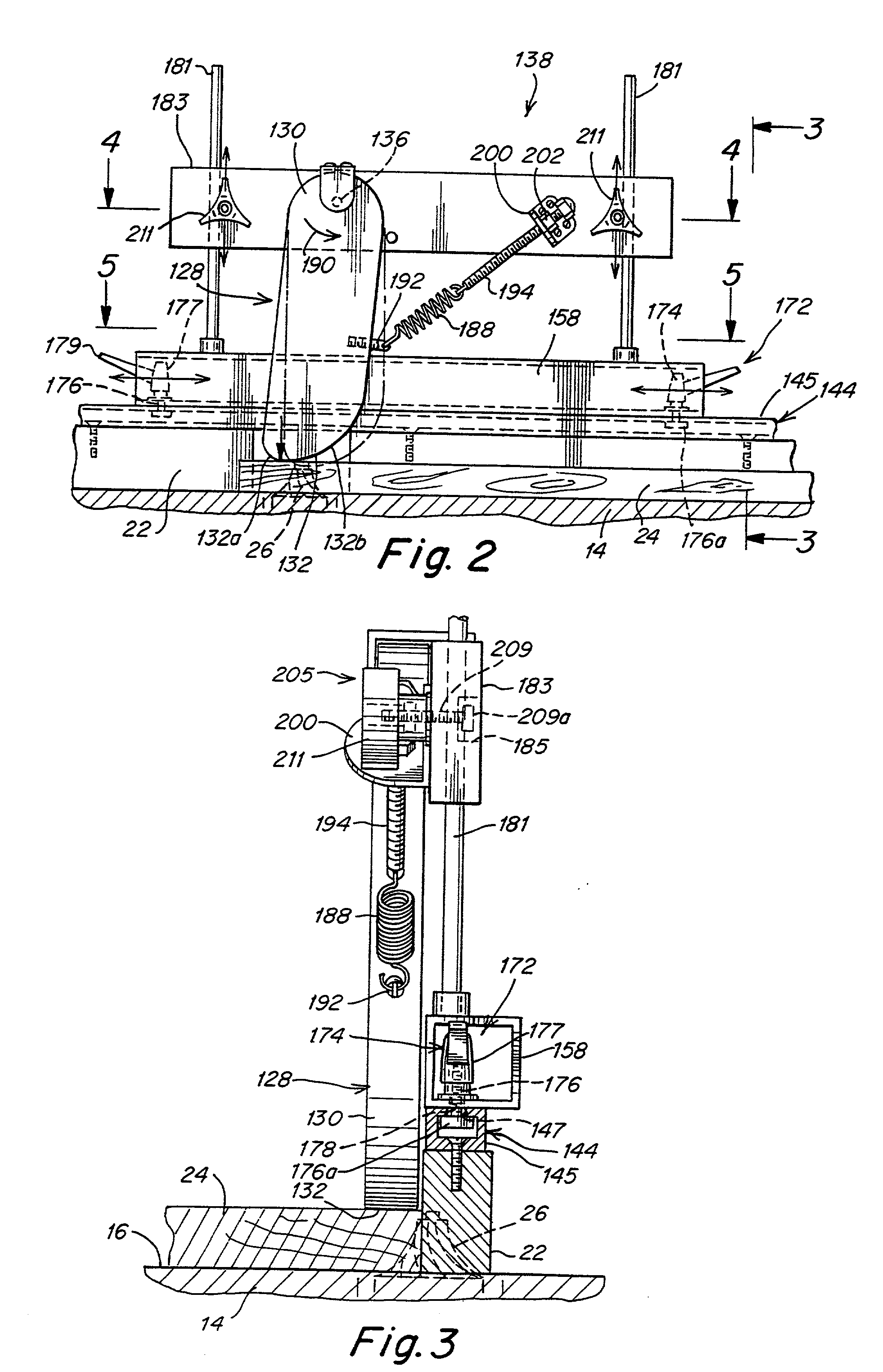

[0040] Referring to the drawings in detail, a combination workpiece positioning / hold-down and anti-kickback device 10 according to the present invention is designed for a use with a work table 12 having a tabletop 14 with an upper surface 16 and opposite transverse sides 18 and 20. As is conventional, a fence 22 is secured at one edge of work table 12. During operation, a workpiece 24, such as a piece of wood, is positioned on upper surface 16 and against fence 22. Then, a woodworking operation is performed by a woodworking tool such as a saw, router 26 and the like, while workpiece 24 is moved in the lengthwise direction 27 of work table 12, against fence 22.

[0041] In order to press workpiece 24 against fence 22, combination workpiece positioning / hold-down and anti-kickback device 10 includes a positioning member 28 having a main body 30 with a generally oblong shape, and an arcuate cam surface 32 at one shorter edge of main body 30 for engaging a side surface of workpiece 24 on wo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| biasing force | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com