Ball screw device and steering system

a technology of ball screw and steering system, which is applied in the direction of power-driven steering, vehicle components, gearing, etc., can solve the problems of reducing the precision of the shape of the retainer groove, and achieve the effect of suppressing variation or increasing rotational torqu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

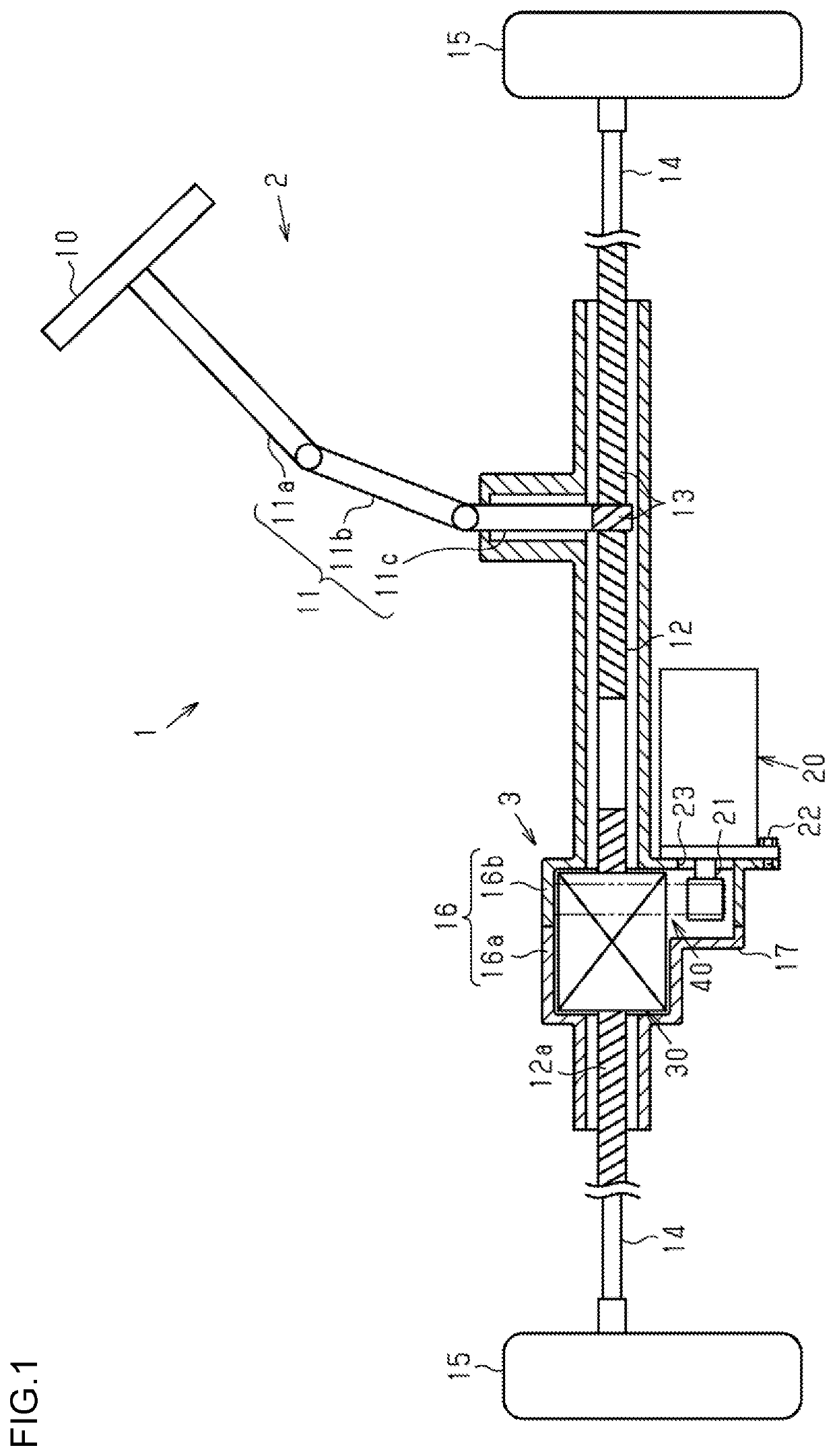

[0018]An electric power steering system (EPS) that is a steering system according to one embodiment of the present invention is described below. As illustrated in FIG. 1, an EPS 1 includes a steering operation mechanism 2 configured to turn steered wheels 15 based on a driver's operation for a steering wheel 10, and an assist mechanism 3 configured to assist the driver's steering operation.

[0019]The steering operation mechanism 2 includes the steering wheel 10 and a steering shaft 11 to be rotated integrally with the steering wheel 10. The steering shaft 11 includes a column shaft 11a coupled to the steering wheel 10, an intermediate shaft 11b coupled to the lower end of the column shaft 11a, and a pinion shaft 11c coupled to the lower end of the intermediate shaft 11b. The lower end of the pinion shaft 11c is coupled to a rack shaft 12 serving as a ball screw shaft through intermediation of a rack and pinion mechanism 13. The lower end (pinion teeth) of the pinion shaft 11c meshes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com