Wall washer

a technology for wall washers and washers, applied in fixed installations, light and heating equipment, semiconductor devices for light sources, etc., can solve the problem of not being able to achieve a sufficiently good light distribution by just these measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

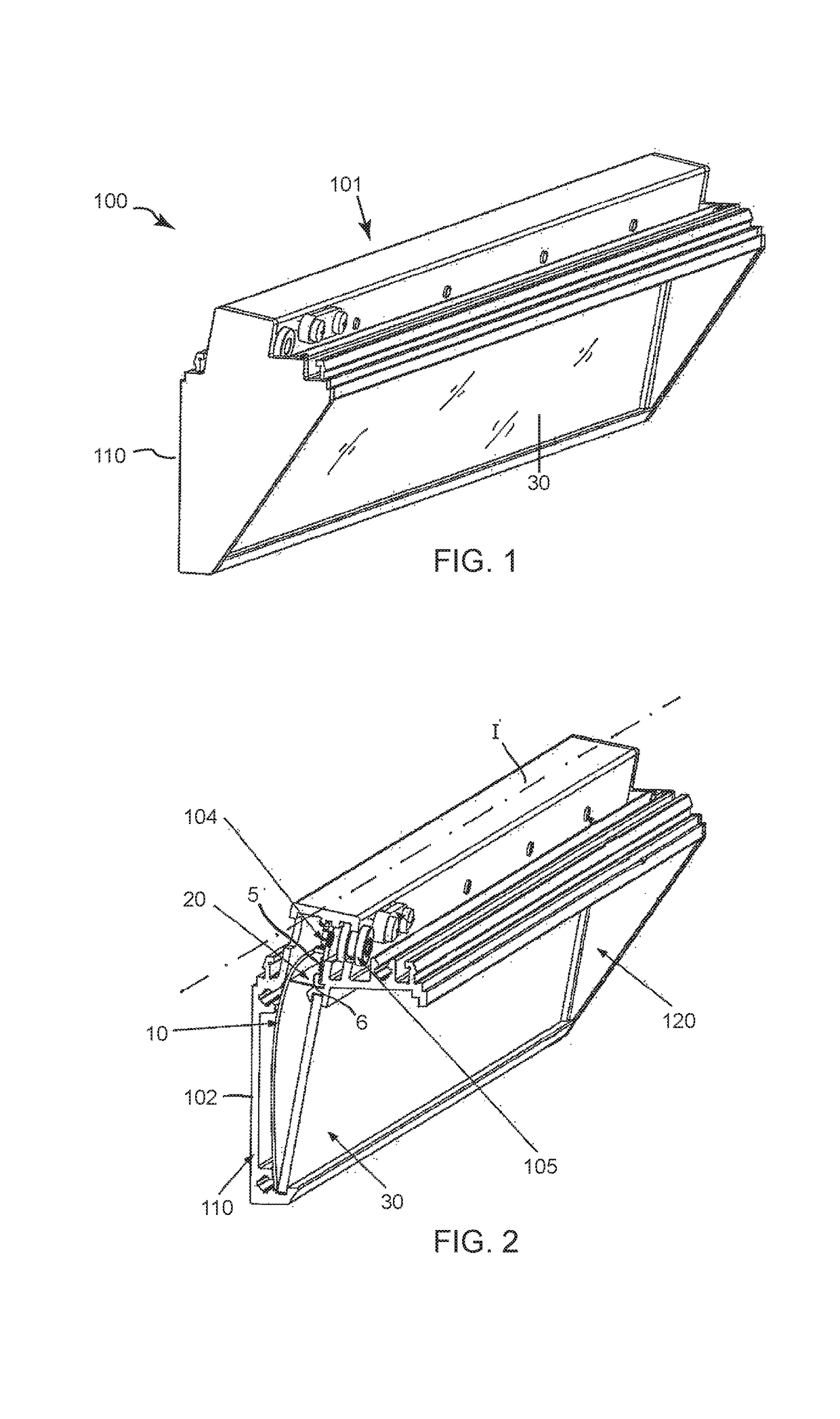

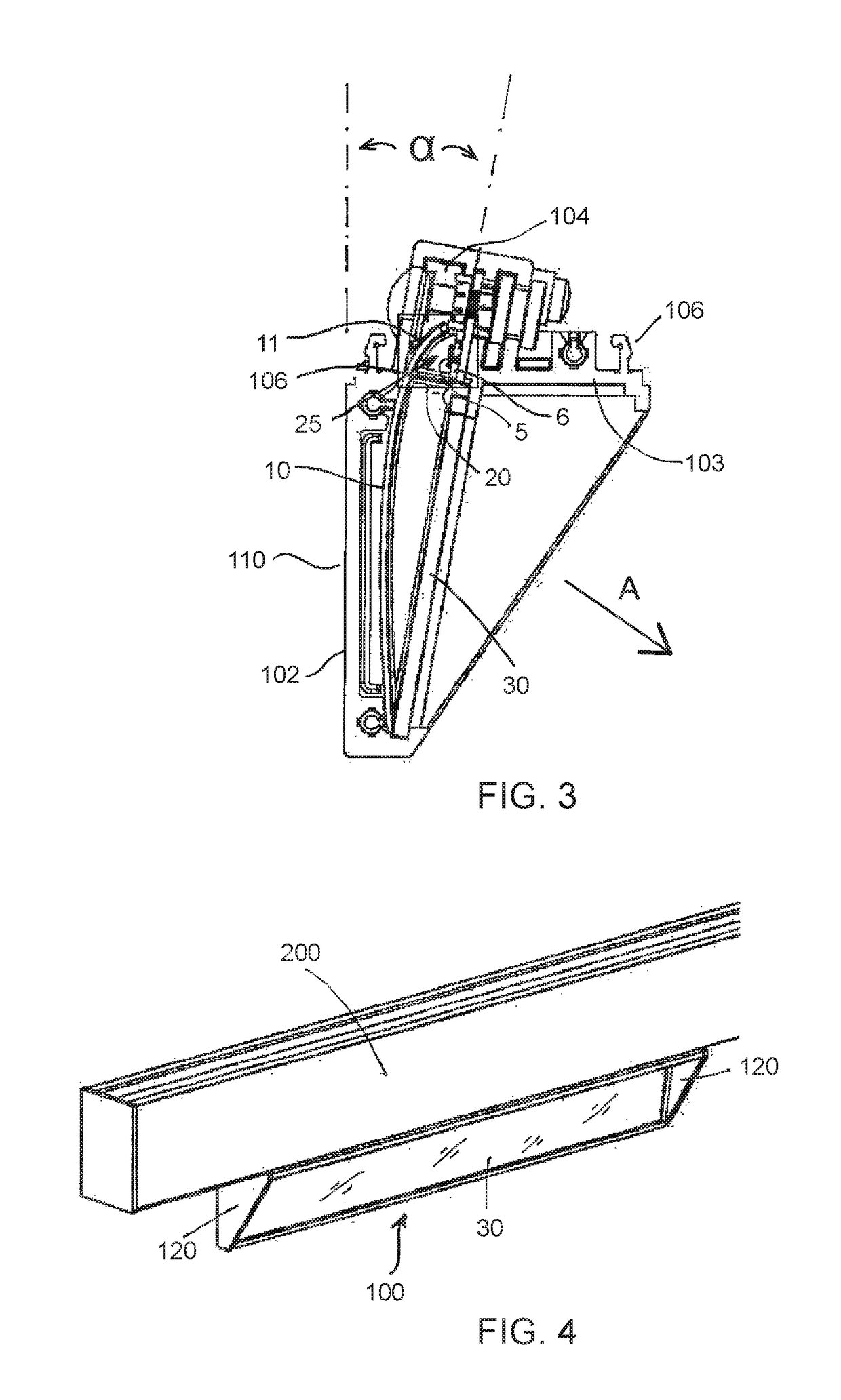

[0020]FIG. 1 illustrates an overall depiction of a lighting fixture according to the invention with the reference number 100, which is to be used as a so-called wall washer, as mentioned above. As is the case with lighting fixtures of this kind, these are attached to a horizontal mounting surface, for example to the ceiling of a room or in a comparable way. In the orientation that is intended for the operation of it, this means that the rear side (reference no. 110 in FIG. 1) of the housing 101 is essentially aligned in a vertical direction. The light of lighting fixture 100 is thereby not emitted horizontally or vertically downwards, but rather obliquely towards the side, so that in the case that the lighting fixture is arranged within the vicinity of a wall, the wall area that is located obliquely below will be illuminated. As it is generally common in the lighting technology, it is hereby intended that the so-called light field that is to be illuminated on the wall, features a br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com