Finishing monoblock with optimised transmission ratio for a billet rolling plant

A technology of rolling equipment and transmission ratio, which is applied in the direction of driving devices for metal rolling mills, manufacturing tools, metal rolling, etc., and can solve the problems of large bearing speed limitations, high manufacturing costs, and high spare parts inventory costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

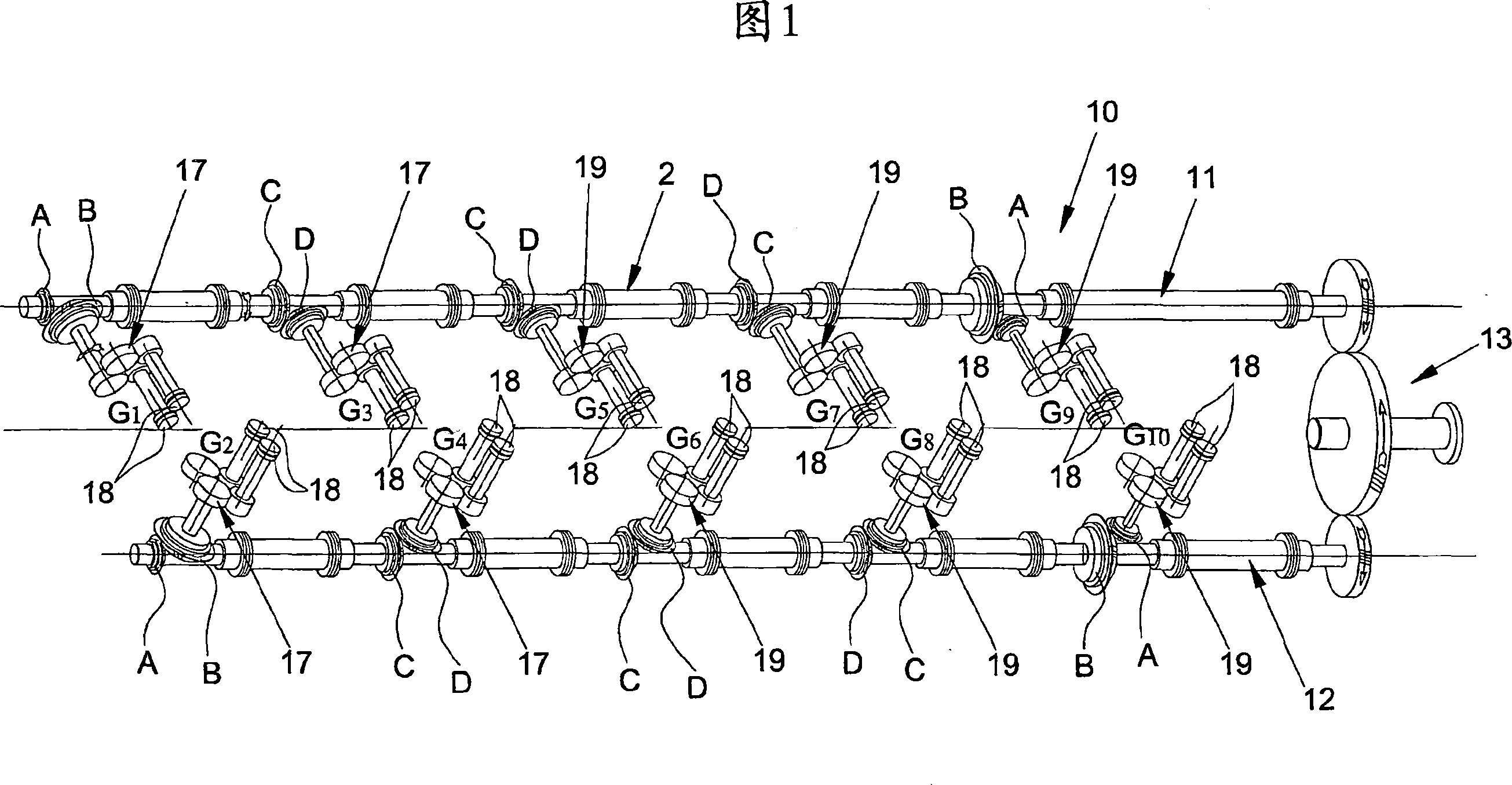

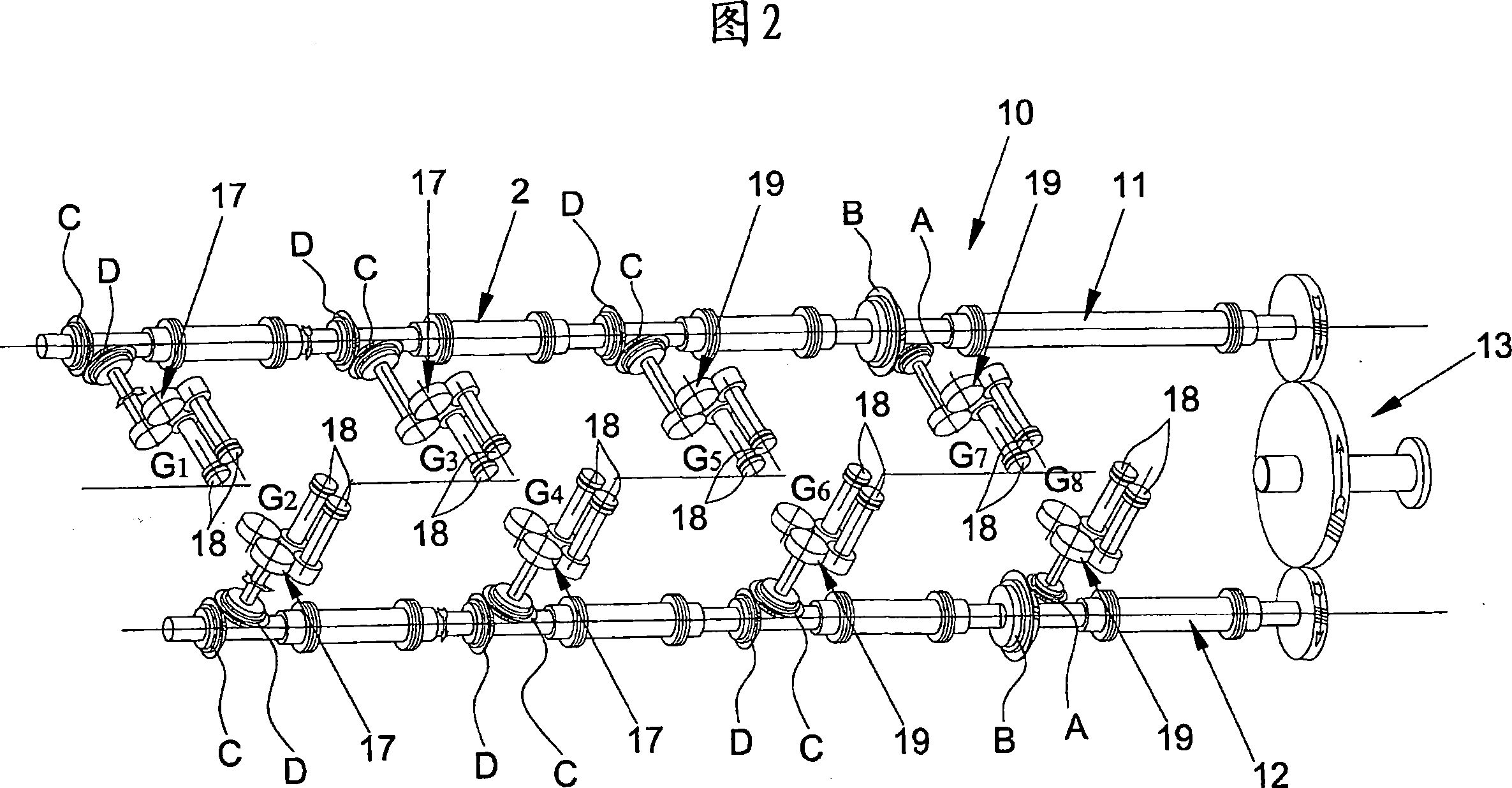

[0023] Referring to the drawings, the overall unit 10 is schematically shown in FIGS. 1 and 2 and has 10 and 8 stations respectively.

[0024] The rolling unit 10 comprises two parallel mechanical transmission structures, namely a first transmission structure 11 and a second transmission structure 12, which are connected by a control reducer 13, which in turn is connected by gears to the working drive motor.

[0025] The mechanical transmission structure is equipped with bevel gear pairs A, B, C, D and a gear 17 that transmits the rotation in cascade to the individual stands G1, G2, ..., Gn of the rolling unit 10 rolling roll 18.

[0026] In the example shown, such a monolithic unit has ten rolling stands G1-G10 (FIG. 1) or eight rolling stands G1-G8 (FIG. 2) respectively in succession, which optionally Controlled by two transmission structures 11 and 12, so that the first transmission structure 11 controls odd-numbered stations G1, G3, ..., G9 (or G7), while the second trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com