Negative valence jump dynamic torsion corrector

A dynamic torque and calibration device technology, applied in the direction of measuring devices, force/torque/power measuring instrument calibration/testing, instruments, etc., can solve frequent reversing, emergency braking, quick start, sudden acceleration or Problems such as deceleration, inability to accurately and timely reflect the peak value of dynamic torque, and low confidence in numerical values have achieved the effects of improving reliability and operability, good economy, and good repeatability

Inactive Publication Date: 2010-08-25

704TH RES INST OF CHINA SHIPBUILDING IND CORP

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In some power systems, especially in the power system of vehicles, it is necessary to frequently carry out unsteady conditions such as reversing, emergency braking, quick start, sudden acceleration or deceleration, etc., and there will be a large Dynamic load, at this time, the transmission parts will bear a huge instantaneous torque peak value, if the designer or operator of the equipment has no idea about the size of this data, it may cause serious overloading, damage, or even major accidents of the equipment; the existing The equipment is equipped with torque meters for measuring torque in some important occasions, but the torque sensors of these torque meters can only measure the torque value under normal conditions, but cannot accurately and timely reflect the size of the dynamic torque peak value; In the power system with peak torque, the torque sensor equipped with it must first master the dynamic characteristics of the torque sensor, that is, know its natural frequency and damping ratio, so as to meet the frequency response of the torque of the power system; Without such correct dynamic characteristic data, it is calculated through mathematical modeling. Even if it is calculated by software simulation, the confidence level of the obtained value is not high, because these calculations are affected by complex environmental conditions, especially the influence of the torque sensor's own damping. Therefore, the industry provides various types of negative-step dynamic torque calibration devices, such as a small-scale negative-step dynamic torque calibration device. The frame of the device is equipped with torque piers, torque walls and negative step generators. The input end of the sensor on the torque pier is connected with a thin steel wire, and the thin steel wire is connected through the guide pulley of the torque wall and the weight of the negative step generator. During the calibration operation, use scissors to cut the thin steel wire with a diameter of less than 1 mm, and the hanging weight will fall. The load on the calibrated test piece is suddenly released, let it dampen the harmonic oscillation, and display in the automatic control system, collect, process, and verify the dynamic characteristics of the sensor to achieve its calibration function. However, the waveform diagram of this device shows a falling edge It is not smooth at the time of shearing. If the weight is heavier, the diameter of the steel wire must be increased, and the shearing is difficult, and the time of the falling edge in milliseconds cannot be guaranteed. Its application is limited. Also in the small range, the technical solution is to hammer brittle materials. (Glass rod), instead of cutting, to make the hanging weight fall, the waveform diagram shows that the falling waveform is worse, and the application range is also limited; another technical solution is to use a device composed of shock tubes, generally in about 10 milliseconds. The pressure can only be stable, and its accuracy is poor, about 6%; the negative step pressure generator of the quick-opening valve device provided by BRL in the United States has a maximum step pressure of 1000MPa, but its rise time is still long (on the order of milliseconds) ), in addition, its pressure value is extremely high, and the device must have good conditions for high-pressure resistance and high-pressure sealing, so that the production and use costs of the device are very high, and it is difficult to popularize and use

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

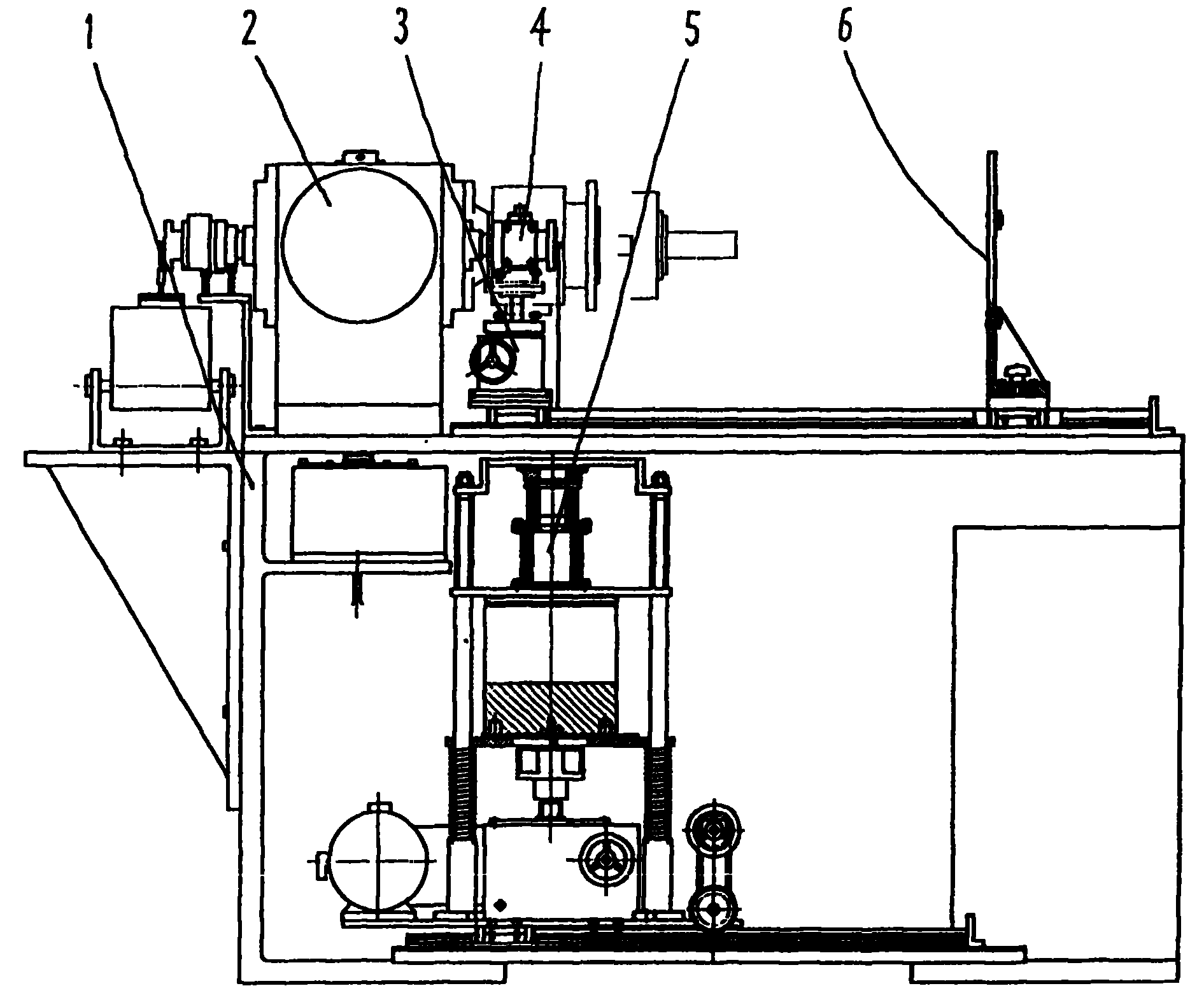

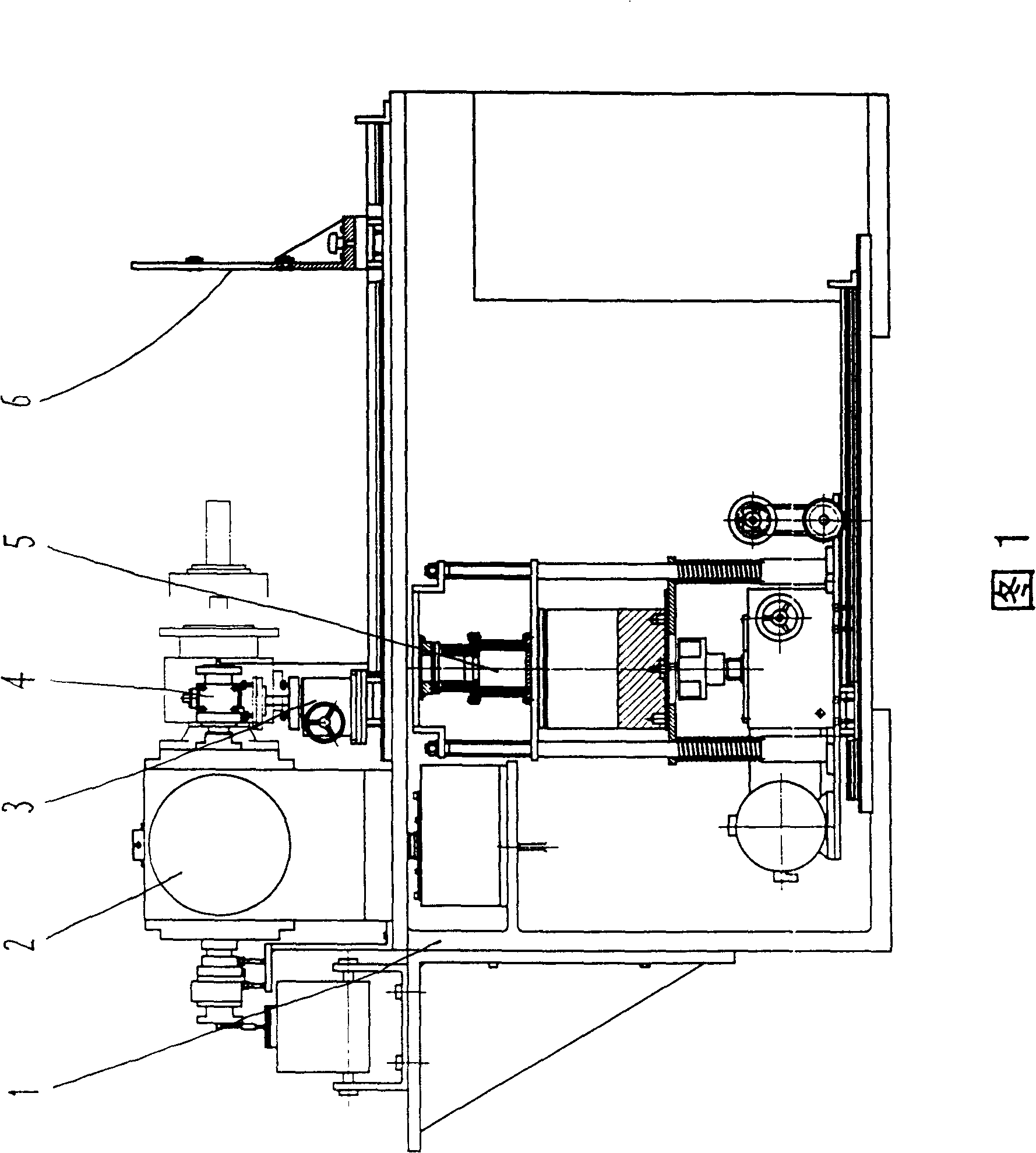

The invention is in use for solving technical issue of generating favorable signal index. The technical scheme is as following: a cylinder module is setup on the torque generator; the cylinder module includes piston, cylinder body, air tank, and connecting rod; the cylinder is connected to cordage around a torque wall; two ends of the connecting rod are connected to armature and piston respectively; inner cavity of the cylinder body in the cylinder module is connected to the inner cavity of the air tank. The invention is suitable to calibrate each negative stepped dynamic torque.

Description

Technical field: The invention relates to a calibration for a torque measuring instrument, in particular to a calibration device for a torque measuring instrument. Background technique: In some power systems, especially in the power system of vehicles, it is necessary to frequently carry out unsteady conditions such as reversing, emergency braking, quick start, sudden acceleration or deceleration, etc., and there will be a large Dynamic load, at this time, the transmission parts will bear a huge instantaneous torque peak value, if the designer or operator of the equipment has no idea about the size of this data, it may cause serious overloading, damage, or even major accidents of the equipment; the existing The equipment is equipped with torque meters for measuring torque in some important occasions, but the torque sensors of these torque meters can only measure the torque value under normal conditions, but cannot accurately and timely reflect the size of the dynamic torque ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01L25/00

Inventor 李涛商维绿陈永培刘中严康平

Owner 704TH RES INST OF CHINA SHIPBUILDING IND CORP

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com