Gene chip sample applying nozzle

A gene chip and spotting technology, applied in printing and other directions, can solve the problems of cleaning, drying, difficult sample loading, high manufacturing cost, complicated process, etc., and achieve the effects of easy cleaning and drying, low cost, and easy manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments:

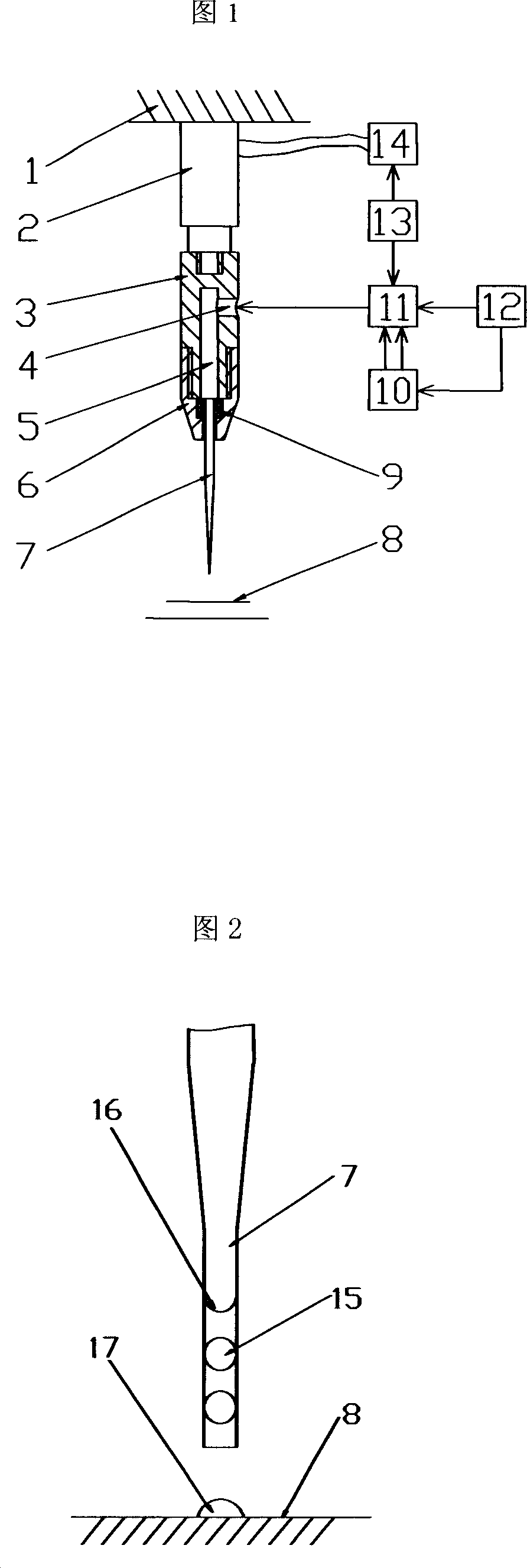

[0017] In FIG. 1, the gene chip spotting nozzle is mainly composed of a micro nozzle 7, a clamping and fixing device, a piezoelectric ceramic driver 2, a driving power source 14, a control valve 11, and a control computer 13. The fixed body 3, the sealing element 9, and the screw cap 6 constitute a clamping and fixing device. The large end of the micro nozzle 7 is matched with the sealing element 9 and placed in the cavity of the screw cap 6. The screw cap 6 is connected with the external thread at one end of the fixed body 3 through an internal thread. The elastic deformation of the sealing element 9 makes the micro nozzle 7 is tightly fixed on the longitudinal axis of the spotting nozzle. The other end of the fixed body 3 is rigidly connected to the external thread of one end of the piezoelectric ceramic driver 2 through an internal thread, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com