Bicycle having multiple tube frame structure.

A technology of bicycle frame and tube structure, which is applied in the direction of bicycle frame, bicycle accessories, bicycle saddle, etc., and can solve the problems of thin-wall longitudinal bending and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The same reference numerals refer to the same parts throughout the drawings.

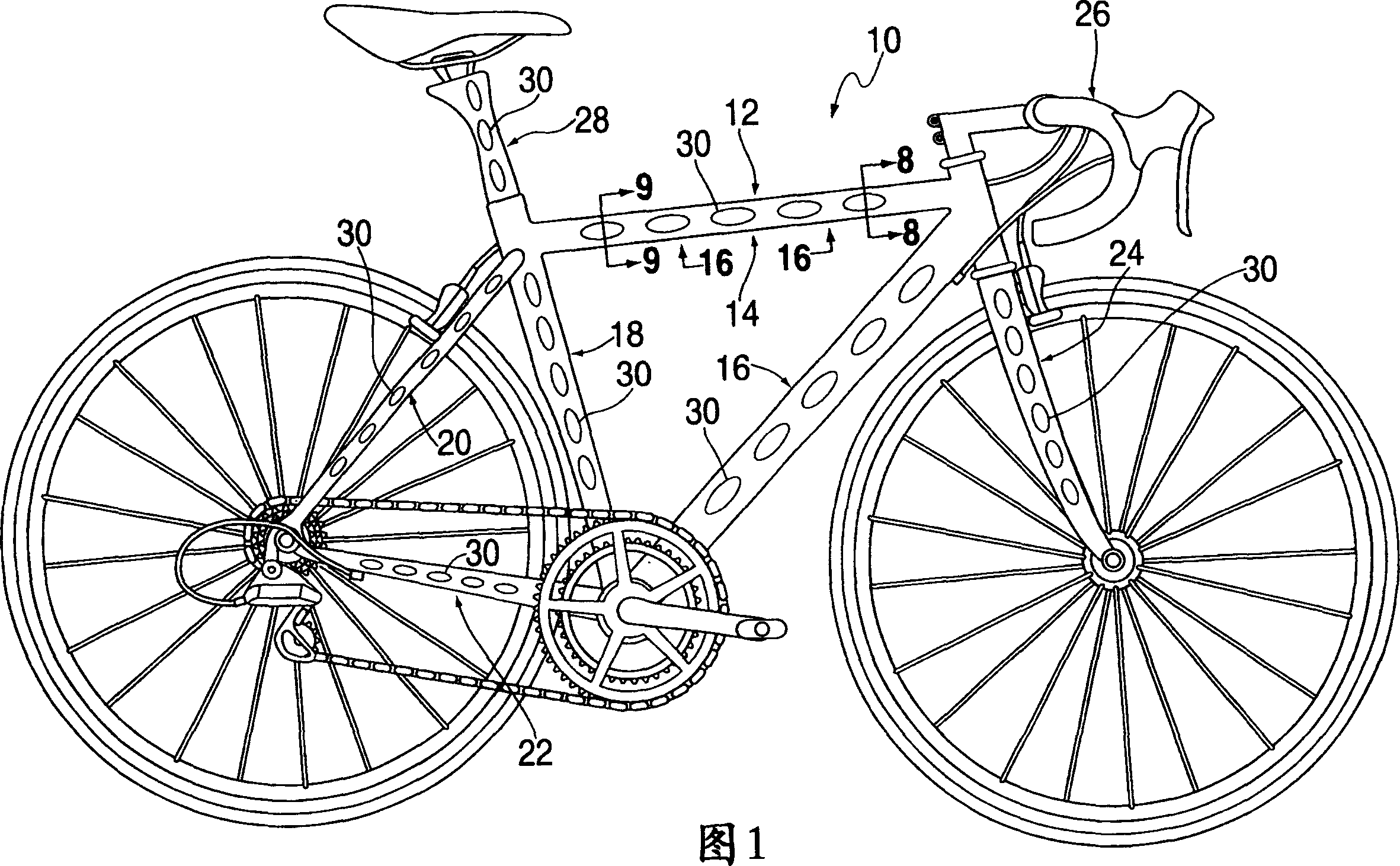

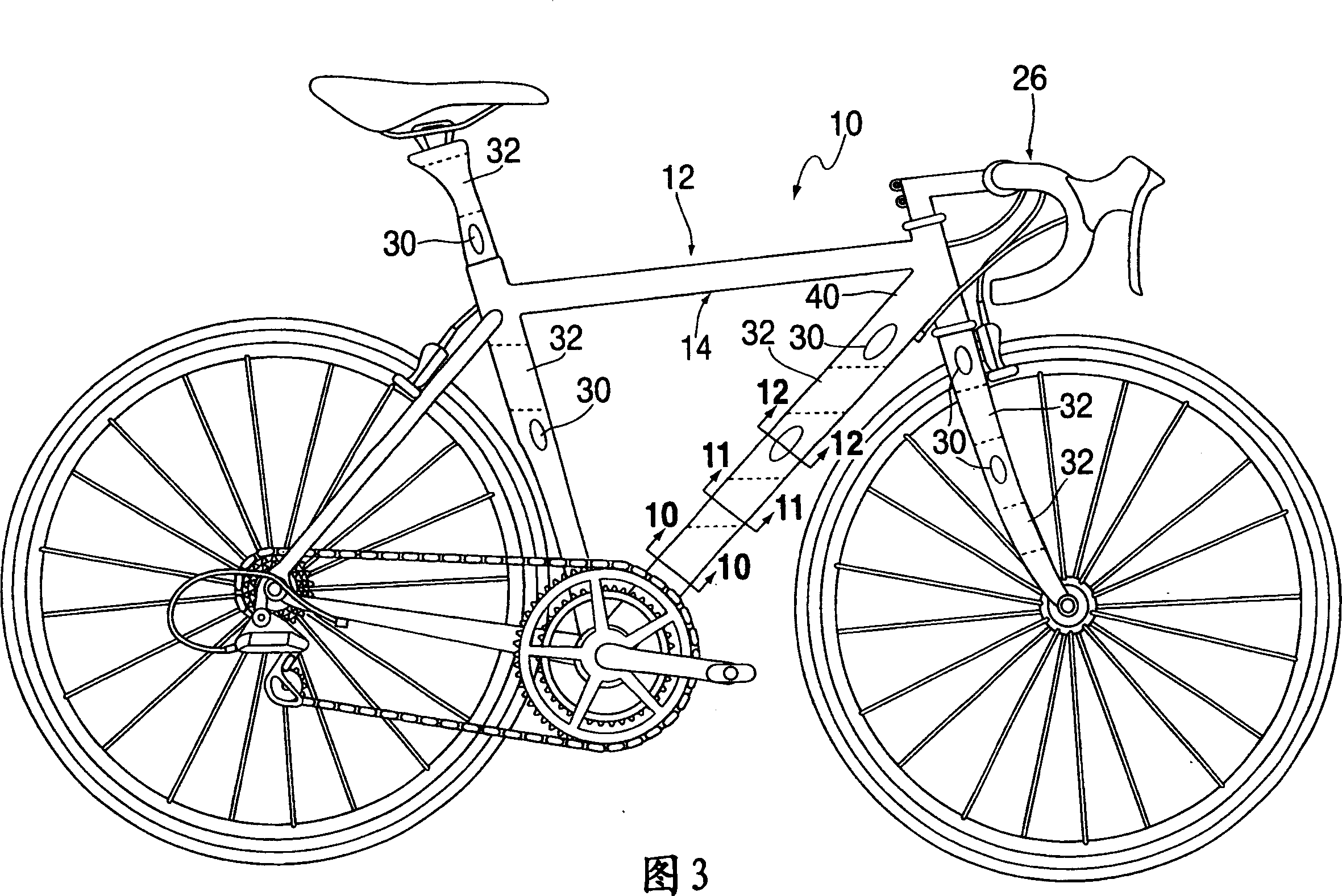

[0059] FIG. 1 shows a bicycle, generally designated by the reference numeral 10 . The bicycle 10 includes a frame 12 comprised of a top tube 14 , a down tube 16 , a seat tube 18 , a rear fork 20 and a chain stay 22 .

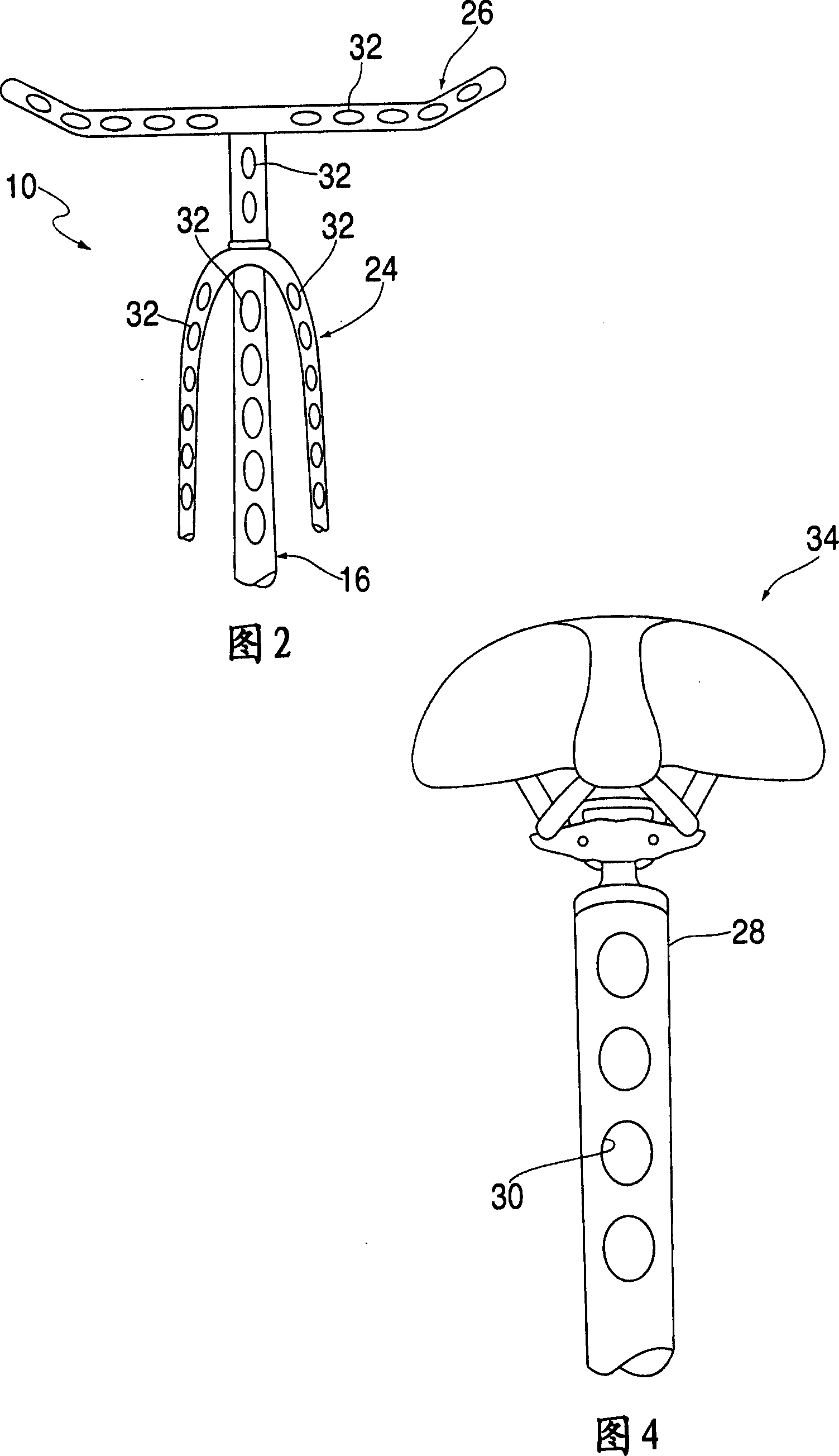

[0060] The bicycle frame also includes a front fork 24 , a handlebar 26 and a seat post 28 .

[0061] Figure 1 shows a preferred embodiment in which each tubular member has a number of openings or "orifices" 30 at 90 degrees to the direction of travel, with the exception of the handlebar 26, which has the orifices oriented to the direction of travel Consistent, but not visible in Figure 1. However, another handlebar design, such as drop bars used on road bikes, benefits from such oriented apertures.

[0062] As described below, each tubular member is formed from two or more tubes which are integrally cast so as to form a common tube wall (or in the case of more than two tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com