Rotary electric shaver

An electric shaver, rotary technology, applied in metal processing and other directions, can solve the problem of the entire electric shaver becoming larger, and achieve the effects of improving shaving experience, increasing the range of shaking angles, and increasing closeness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

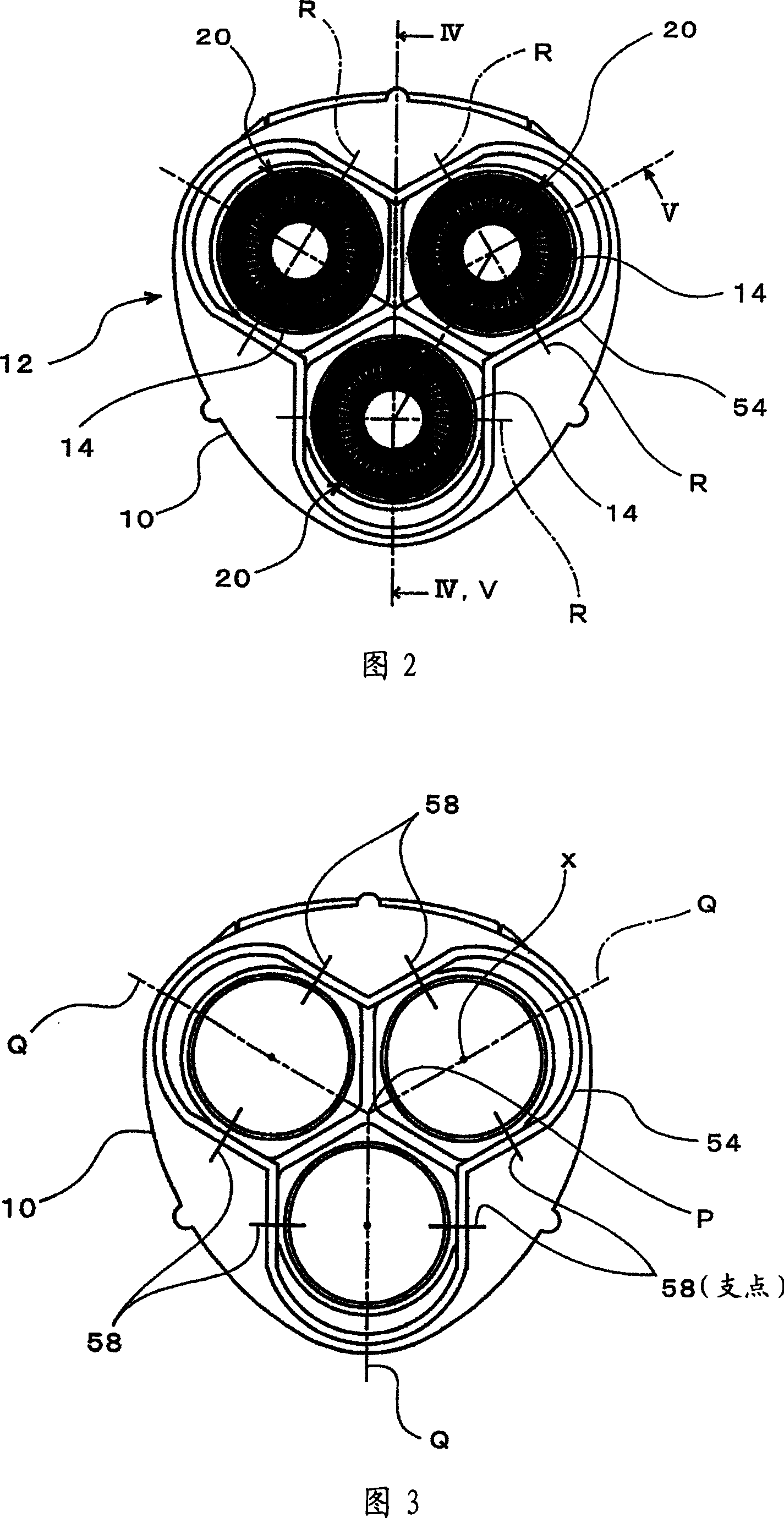

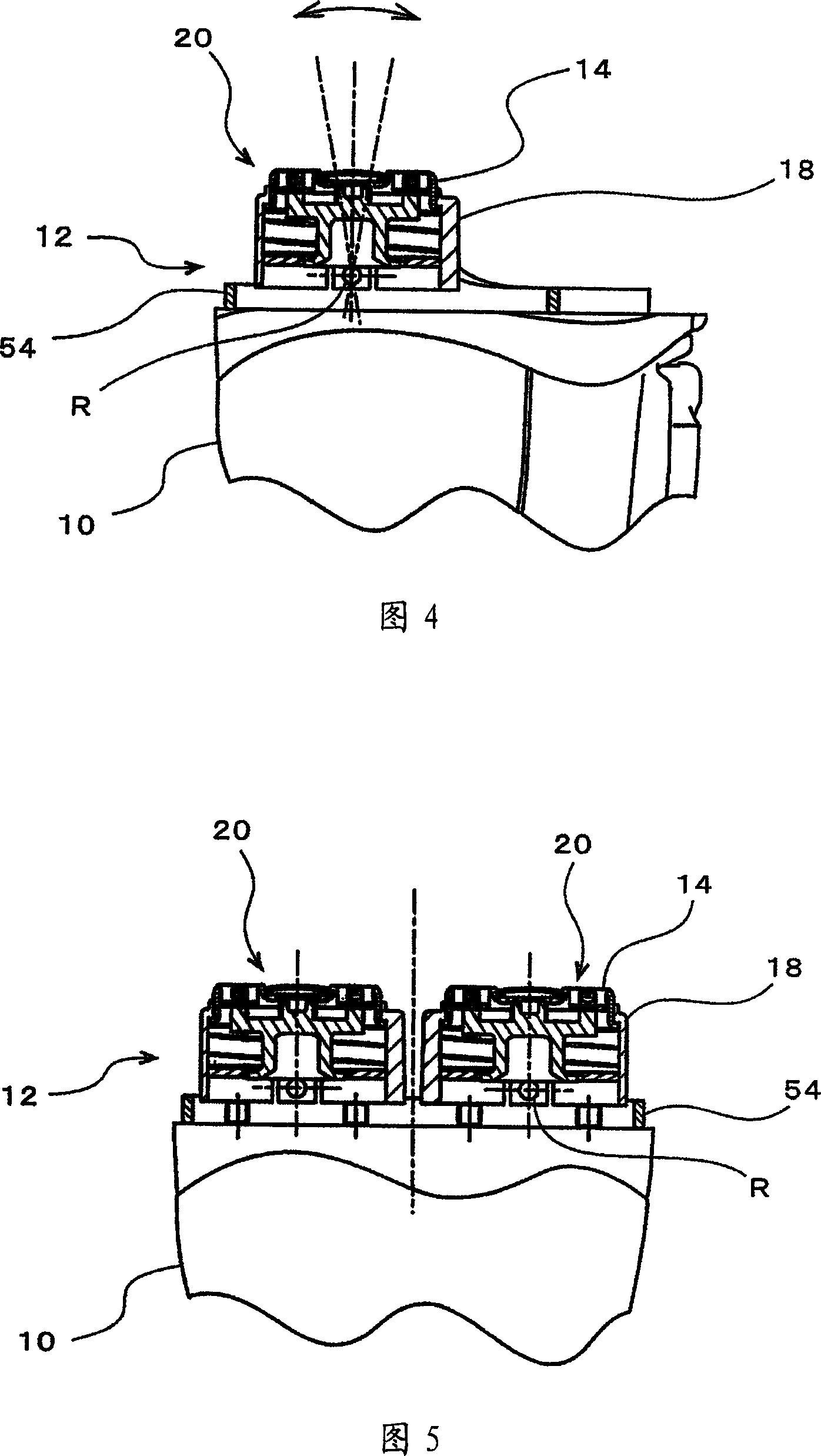

[0042] Fig. 1 is an exploded perspective view showing an embodiment of the present invention partially omitted, Fig. 2 is a top view of a cutting head portion, Fig. 3 is a top view showing a state in which an outer edge is removed from a cutting head portion, and Fig. 4 is a view according to IV of Fig. 2 - Sectional view of line IV, Fig. 5 is a sectional view according to line V-V in Fig. 2, Fig. 6 is an enlarged side sectional view of a blade unit along the rocking axis, Fig. 7 is a top view of a blade frame return spring, Fig. 8 is a top view according to A sectional view taken along line VIII-VIII of FIG. 7 . Moreover, FIG. 9 is an explanatory diagram of a state of use, and is a cutaway view at a position corresponding to the line V-V in FIG. 2 above.

[0043] In FIG. 1, reference numeral 10 is a main body part, and 12 is a blade part attached to this main body part. Three sets of blade units 20 formed of an outer blade 14 , an inner blade 16 described later, a blade fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com