Honeycomb-coal stone for tobacco leaf condensed roasting room and operation method

A dense barn and honeycomb technology, which is applied in the fields of application, tobacco, and tobacco preparation, can solve the problems of poor flue-cured tobacco effect, frequent manual operations, and unstable performance, so as to improve the utilization rate of coal combustion, control accurately, The effect of stable baking temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

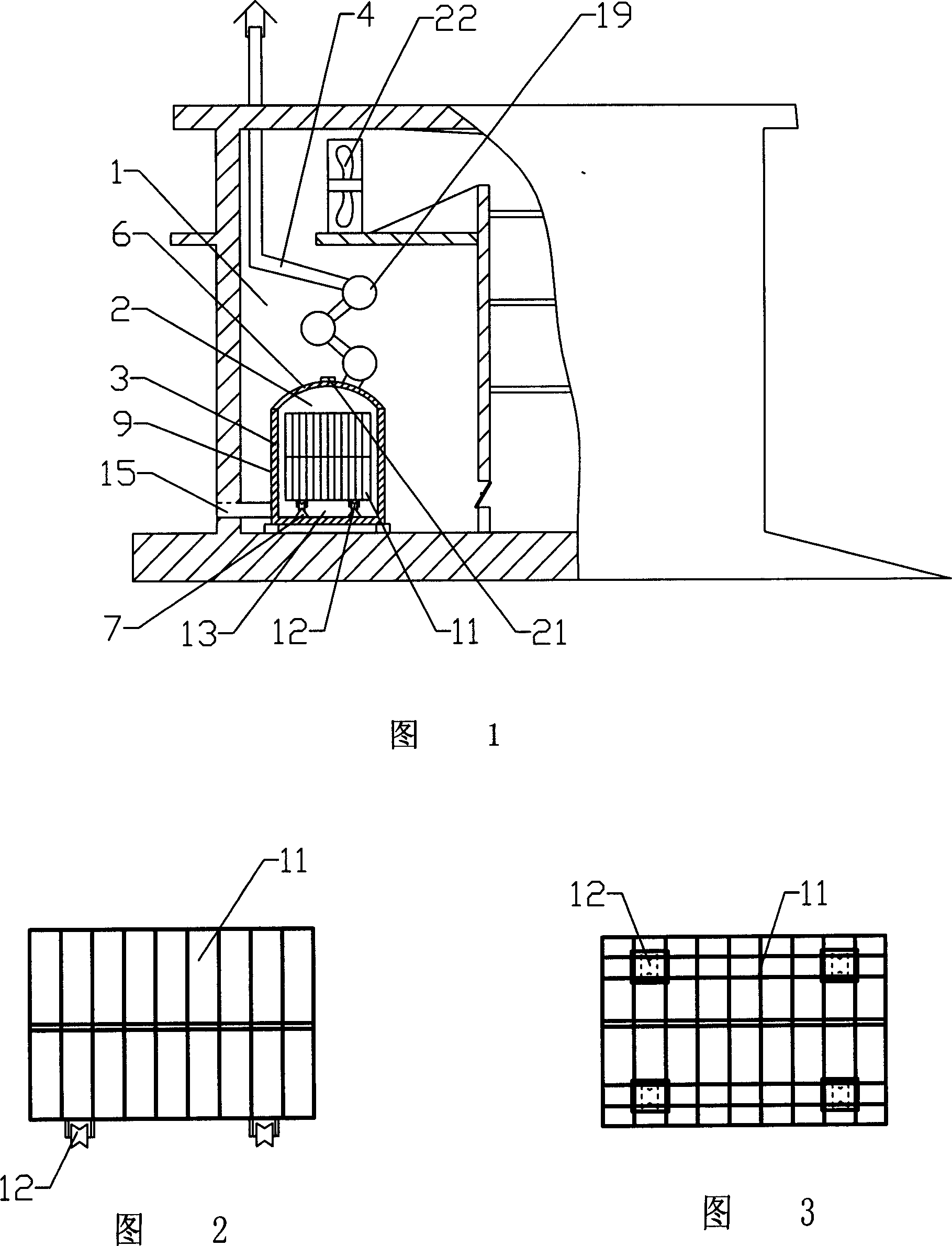

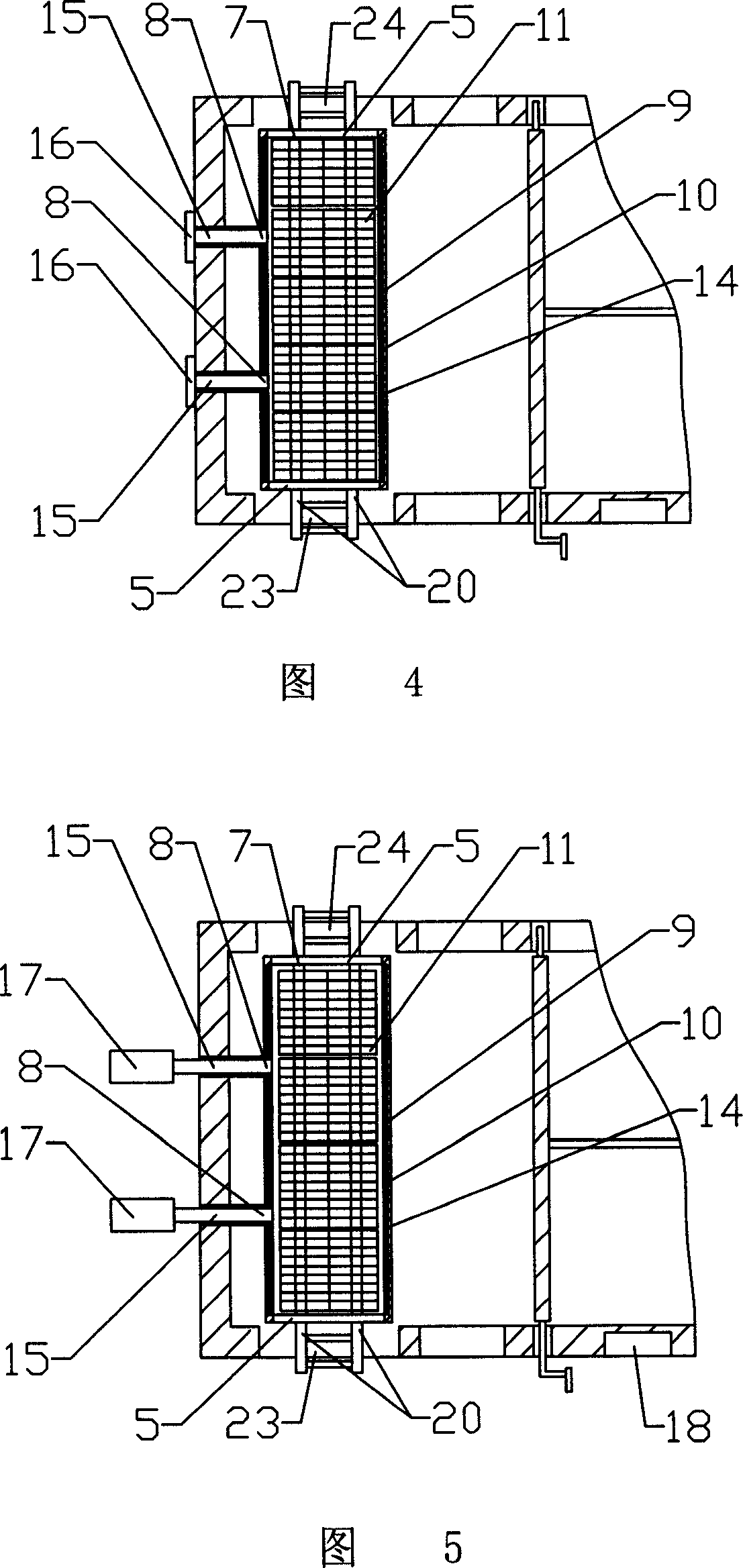

[0032]Embodiment 1, as shown in Fig. 1, Fig. 4, a kind of briquette stove for tobacco leaf intensive barn, one side of barn is provided with heating room 1, and two ventilation combustion-supporting holes 15 are arranged on the wall of heating room 1, ventilation The combustion-supporting hole 15 is provided with a blocking member 16, which can block the ventilation and combustion-supporting hole 15, and can adjust the size of the air inlet of the ventilation and combustion-supporting hole 15. The honeycomb coal furnace 2 is arranged in the heating chamber 1, and the honeycomb coal furnace 2 is a rectangular whole body The combustion chamber comprises a body of furnace 3. The length of the body of furnace 3 is 2.6m, the width is 0.75m, and the height is 0.6m. The chimney 4 has three cylindrical heat exchangers 19 arranged in a triangle, and the cylindrical heat exchanger The diameter of 19 is 0.32m, and length is 2.5m, and the two ends of body of heater 3 are provided with furn...

Embodiment 2

[0033] Embodiment 2, as shown in Fig. 1 and Fig. 5, a kind of briquette furnace for tobacco leaves intensive barn, one side of the barn is provided with a heating chamber 1, and two ventilation and combustion-supporting holes 15 are arranged on the wall of the heating room 1, and the ventilation The combustion-supporting hole 15 is externally connected with a blower 17 whose power is 80W. The blower 17 has an adjustable damper. The blower 17 is electrically connected to the automatic baking controller 18. The briquette furnace 2 is arranged in the heating chamber 1. The briquette furnace 2 is a rectangular whole body combustion The chamber includes a furnace body 3, the length of the furnace body 3 is 2.3m, the width is 0.7m, and the height is 0.6m. The chimney 4 has three cylindrical heat exchangers 19 arranged in a triangle, and the cylindrical heat exchanger 19 The diameter of the furnace is 0.30m, the length is 2m, the two ends of the furnace body 3 are provided with furnac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com