Transducer sheet sealing structure for ultrasonic atomizer

A sealing structure and atomizer technology, which is applied in the direction of fluid, spraying device, liquid spraying device using vibration, etc., can solve the problems of inconvenient disassembly, poor sealing effect, damage to the transducer, etc., so as to achieve convenient and safe installation. The effect of good sealing effect and simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

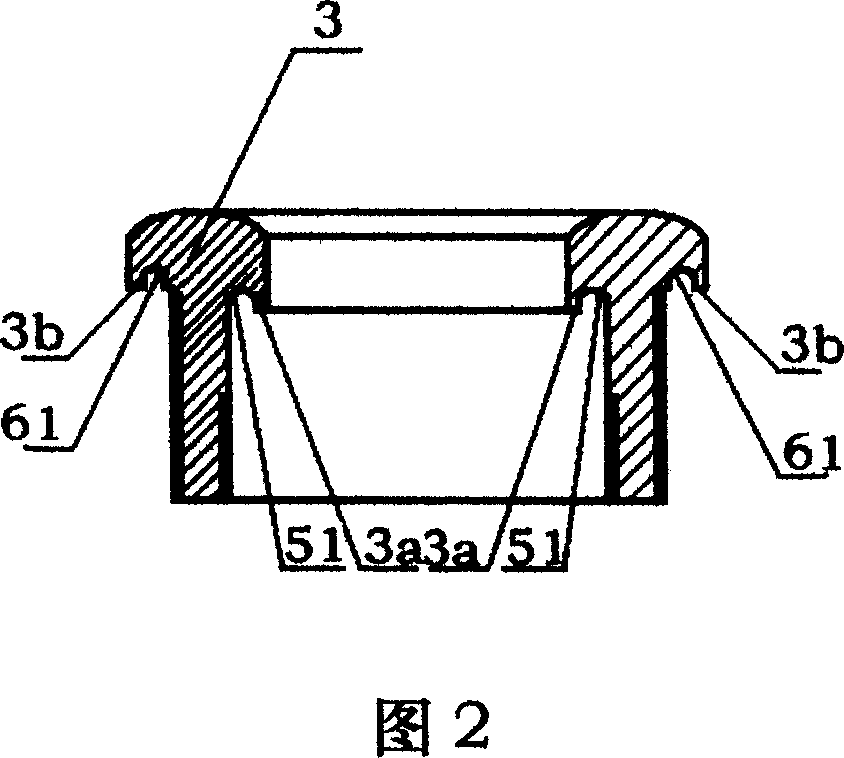

[0023] Embodiment 1: As shown in Figure 3, the ultrasonic atomizer includes a housing 1, and a cavity 2 is arranged on the housing 1; secondly, a control circuit can also be provided in the housing 1, and the control circuit and the transducer plate To electrically connect and drive the transducer sheet, of course, the control circuit can also be arranged outside the casing 1 . The annular gland 3 has a T-shaped inner flange 3a and an outer flange 3b, and an annular groove 51 is provided on the inner flange 3a corresponding to the position of the transducer seal ring 5, and the transducer seal ring 5 is inserted into the annular groove within 51. An outer annular groove 61 is arranged on the position corresponding to the gland sealing ring 6 on the outer flange 3b, and the gland sealing ring 6 is embedded in the outer annular groove 61; the outer wall of the annular gland 3 is provided with threads, and the inner wall of the cavity 2 is provided with The thread that is matche...

Embodiment 2

[0024] Embodiment 2: On the basis of Embodiment 1, the connection relationship between the ring-shaped fixing seat 7 and the ring-shaped gland 3 is set as four screws 9 that are symmetrically distributed by thread fit connection, as shown in Figure 4, and the rest of the structures are the same as The connection relationship is the same as that in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com