Fixing member assembly for bonding wall finishing material and wall finishing material bonding body using the same

A technology for fixing parts and decorative materials, applied in covering/lining, construction, building construction, etc., can solve problems such as difficulty, damage to inner wall surface, complex shape, etc., achieve uniform gaps and improve construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

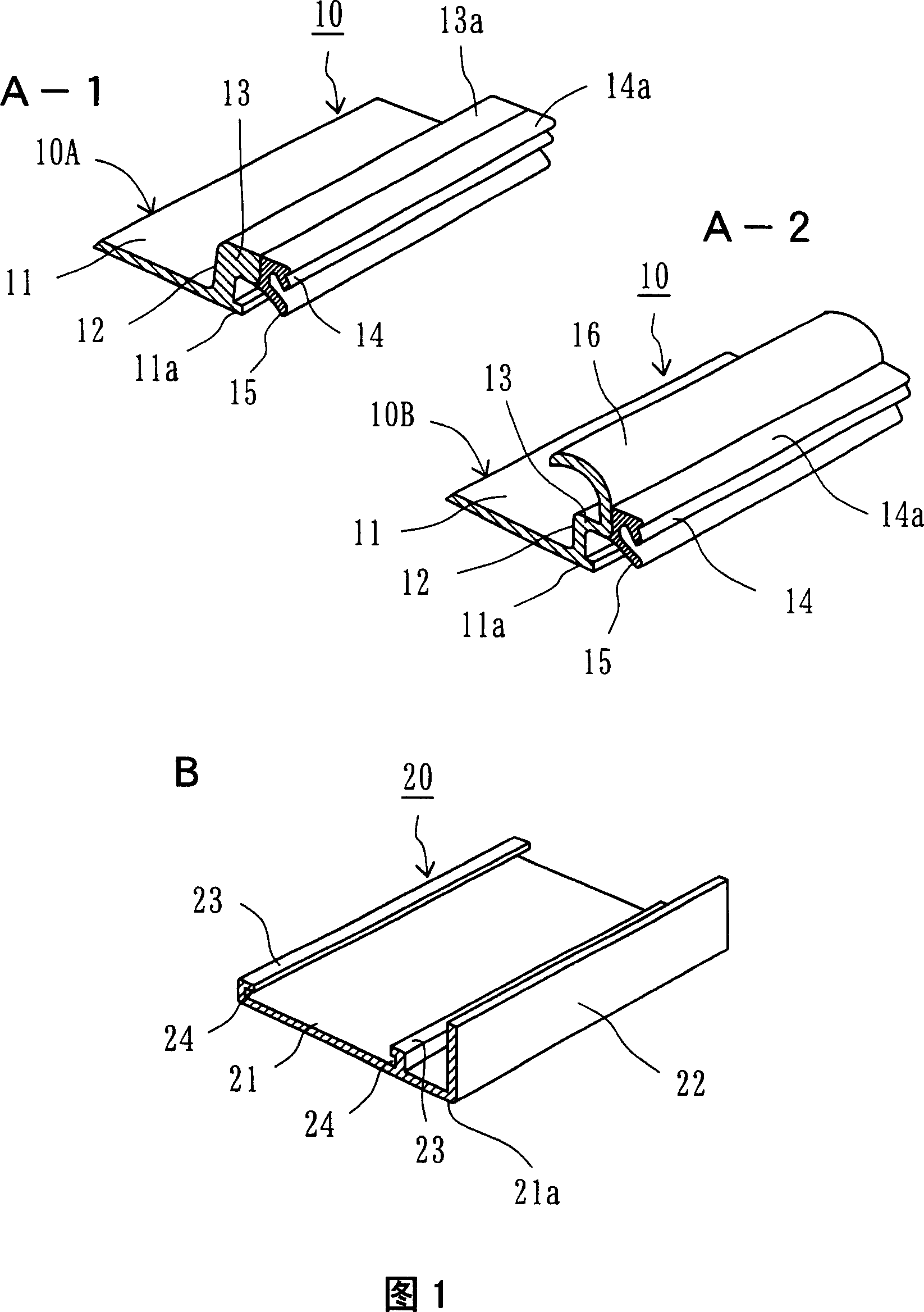

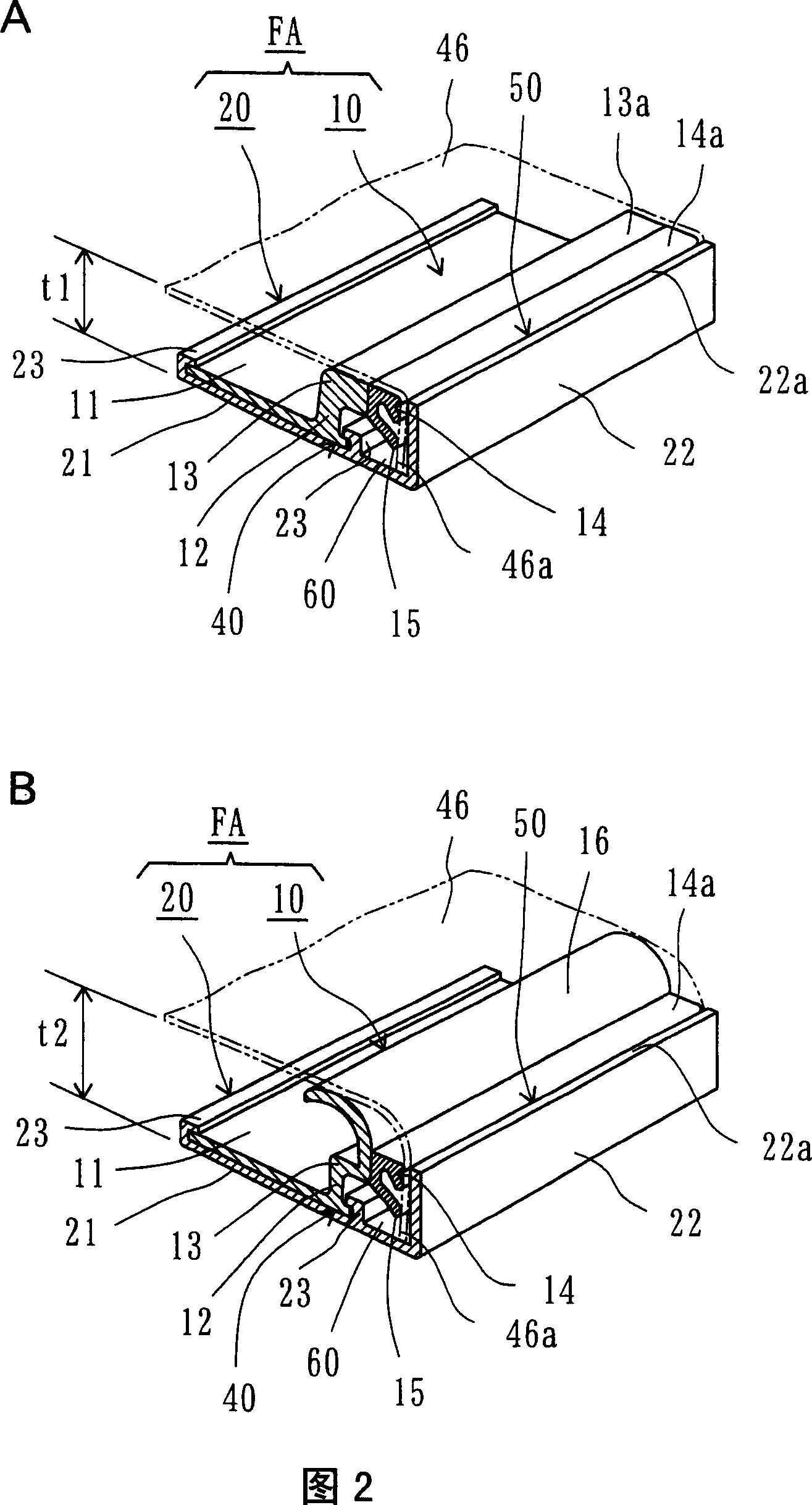

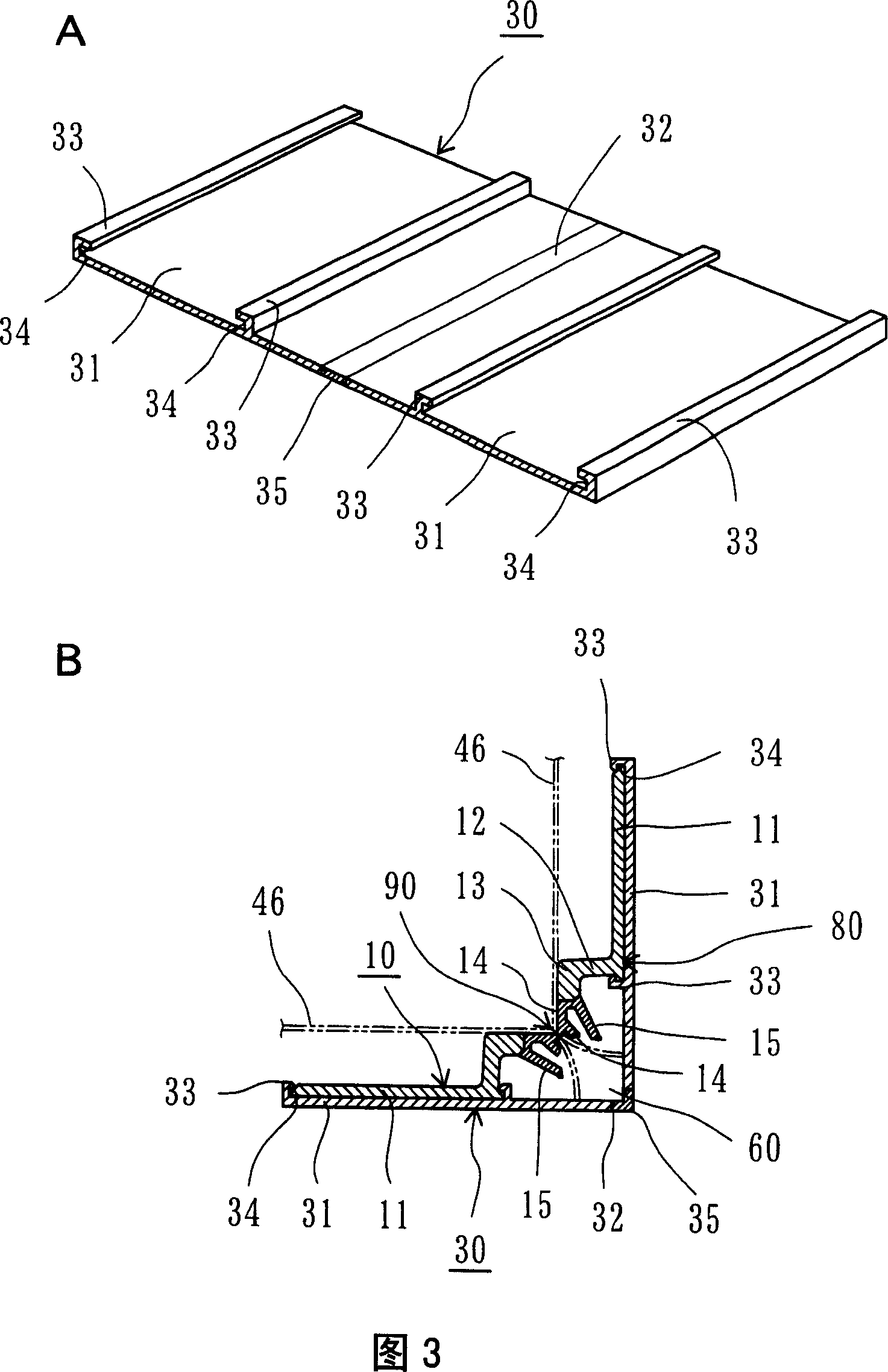

[0065] Next, the fixing member assembly for attaching a wall decorative material according to the present invention will be described in detail with reference to specific examples shown in FIGS. 1 to 5 . Fig. 1 is a diagram showing a basic configuration example of a fixing member assembly for wall decorative material inlay of the present invention, Fig. 1A-1 is a schematic perspective view of a first embodiment of a fixing member main body, and Fig. 1A-2 is a first embodiment of a fixing member main body. A schematic perspective view of the second embodiment, FIG. 1B is a schematic perspective view showing an example of an edge member. Fig. 2 is a diagram showing an example of a combination of a fixing part main body and an edge part, and Fig. 2A shows a combination of the fixing part main body of the first embodiment shown in Fig. 1A-1 on the edge part shown in Fig. 1B A schematic perspective view of the state, FIG. 2B is a schematic perspective view showing a state in which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com