Adhesive composition, method for bonding to a metal surface and rubber to metal adhesive

A technology of adhesives and compositions, applied in surface pretreatment bonding methods, non-polymer adhesive additives, adhesive additives, etc., can solve the problem of not improving sprayability and viscosity stability, and poor spray performance , It is difficult to achieve dry film thickness control and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

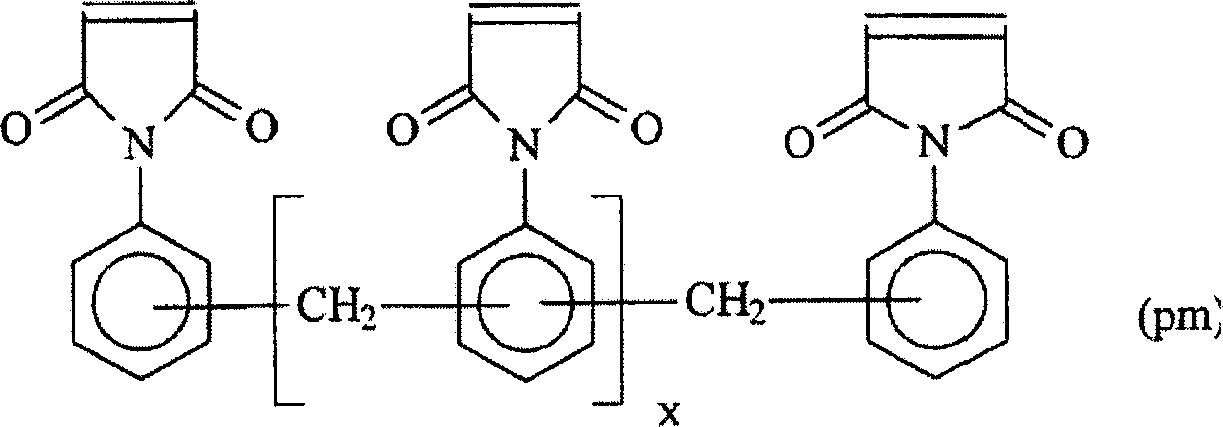

Method used

Image

Examples

Embodiment

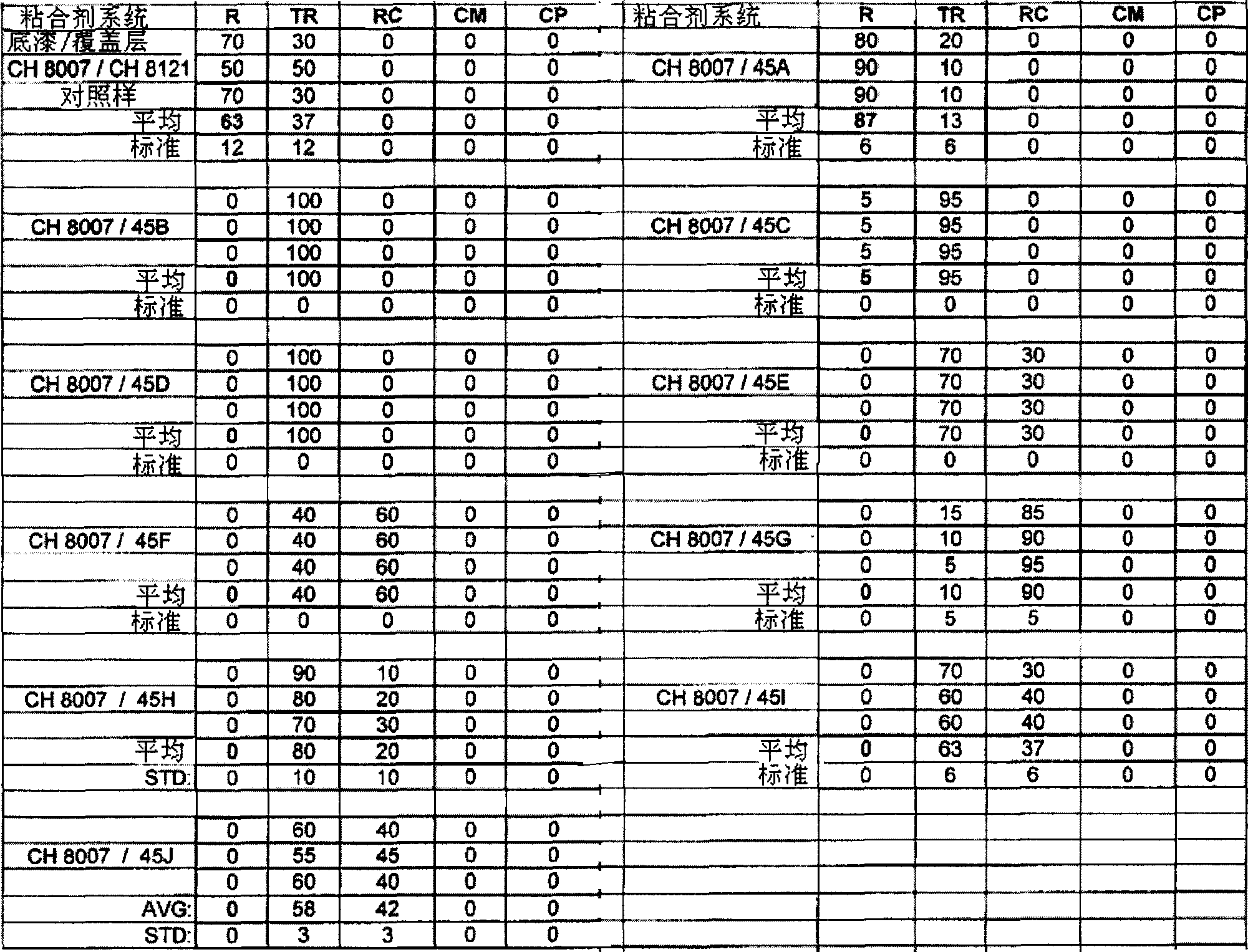

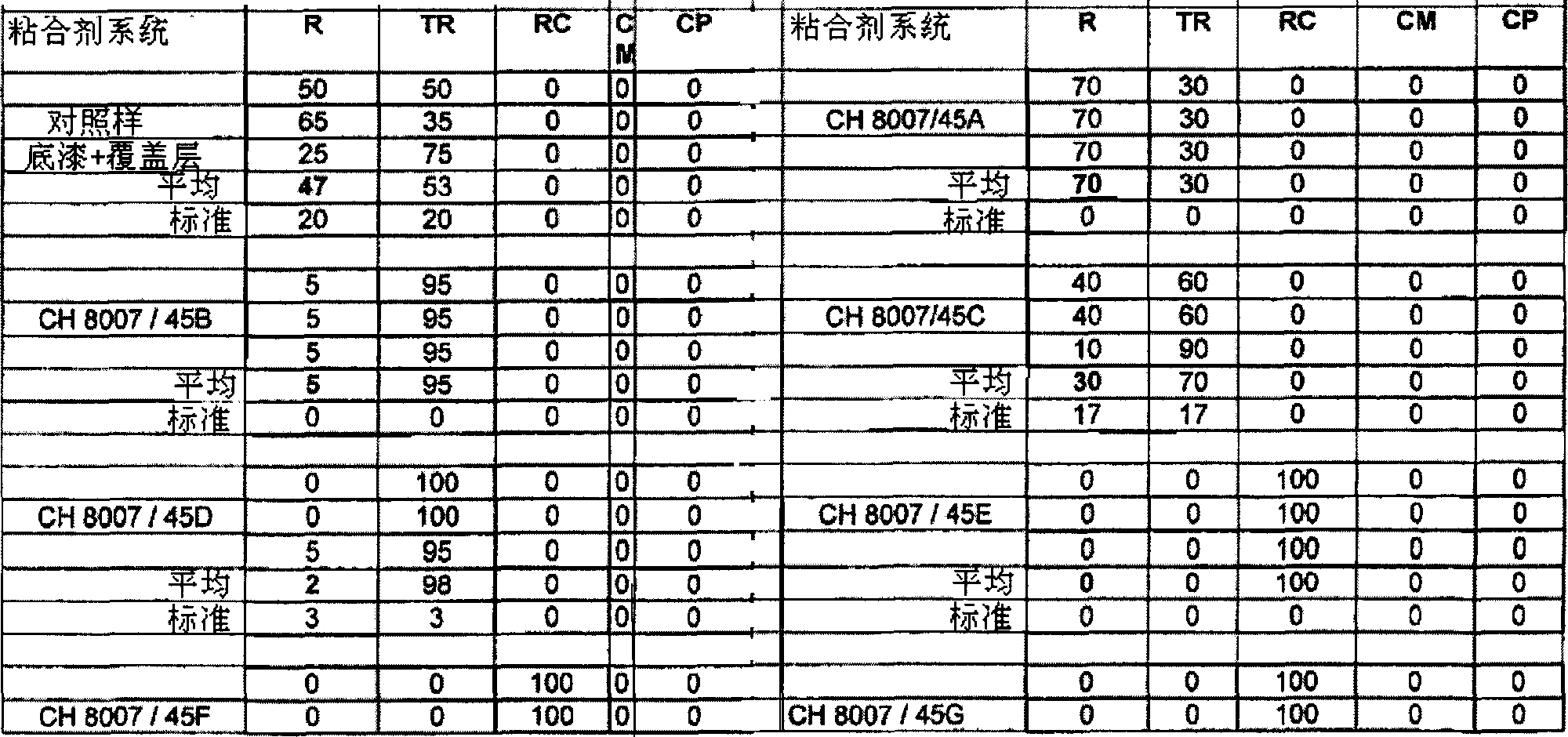

[0065] The tests of the following examples are disclosed to further explain and fully disclose the present invention, and do not limit the scope defined by the claims of the present invention in any way.

[0066] Initial Adhesion (PA) - The bonded part is pulled to separate according to ASTM Test D429 - Method B. The test parts were peeled at a peel angle of 45 degrees. The test is performed at room temperature and a specified test speed is, for example, 2 or 20 inches per minute. After the bonded parts were separated, the peak peel strength (measured in pounds per machine direction inch) and the percent rubber remaining on the bonded coated area of the part were determined.

[0067] 72 Hours Salt Spray (SS) - Sand the edges of the bonded parts with an abrasive wheel. The rubber is then bound to the metal back with stainless steel wire to compress the bonded area. This exposes the bondline to the environment. Scrape the adhesive layer with a razor blade to cause cracks. ...

Embodiment approach

[0126] The 45, 85 and 69 series below represent RTM adhesives that use water as a carrier and wetting aids and dispersants to disperse solids according to the invention. Bonded rubber-metal assemblies were prepared using standard procedures. Some coated samples were placed under prebake / precure heating conditions. After prebaking for the specified time, the adhesive layer portion of the adhesive-coated part was brought to the molding temperature for the specified time (in minutes) before the rubber was injected into the mold cavity. This simulates actual production conditions and helps determine if the adhesive remains sufficiently active to successfully bond rubber compounds.

[0127] Multiple initial adhesion, hot tear, boiling water and salt spray resistance tests were performed with or without prebaking of the adhesive.

[0128] Elastomers Tested: Sulfur vulcanized NR vulcanized at 320 mm for 16 min with a 40-45A durometer.

[0129] Measure hot tear after keeping at 300...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com