Method for measuring acoustics parameter of viscous-elastic material under medium-high frequency

A technology of acoustic parameters and measurement methods, applied in electrical digital data processing, special data processing applications, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., can solve problems that affect the accuracy of testing techniques and sensitivity of material properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Since there is no reference value for the transverse and longitudinal wave parameters of rubber-like viscoelastic materials in the middle and high frequency bands, this method first simulates the method for the elastic materials whose parameters can be consulted.

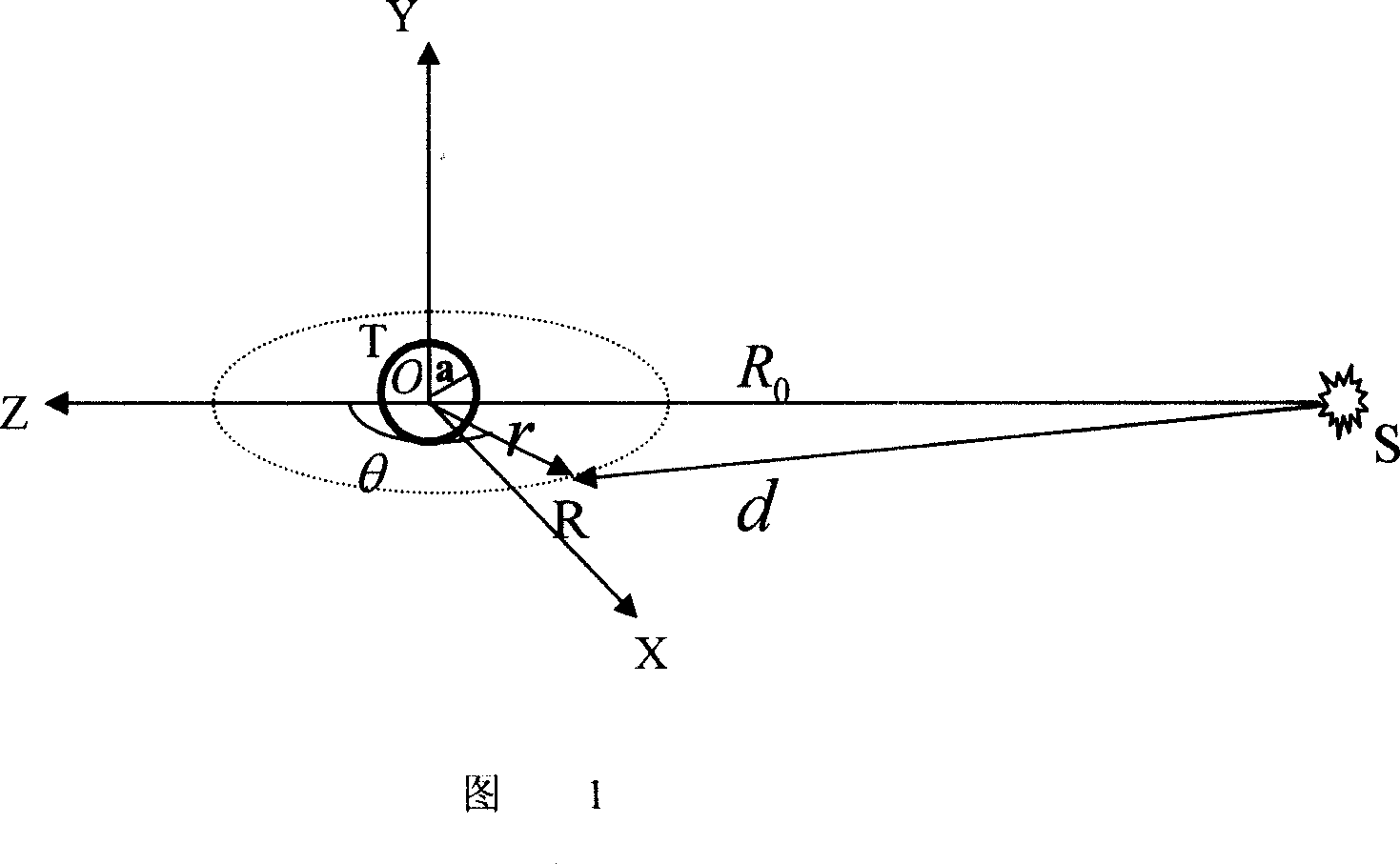

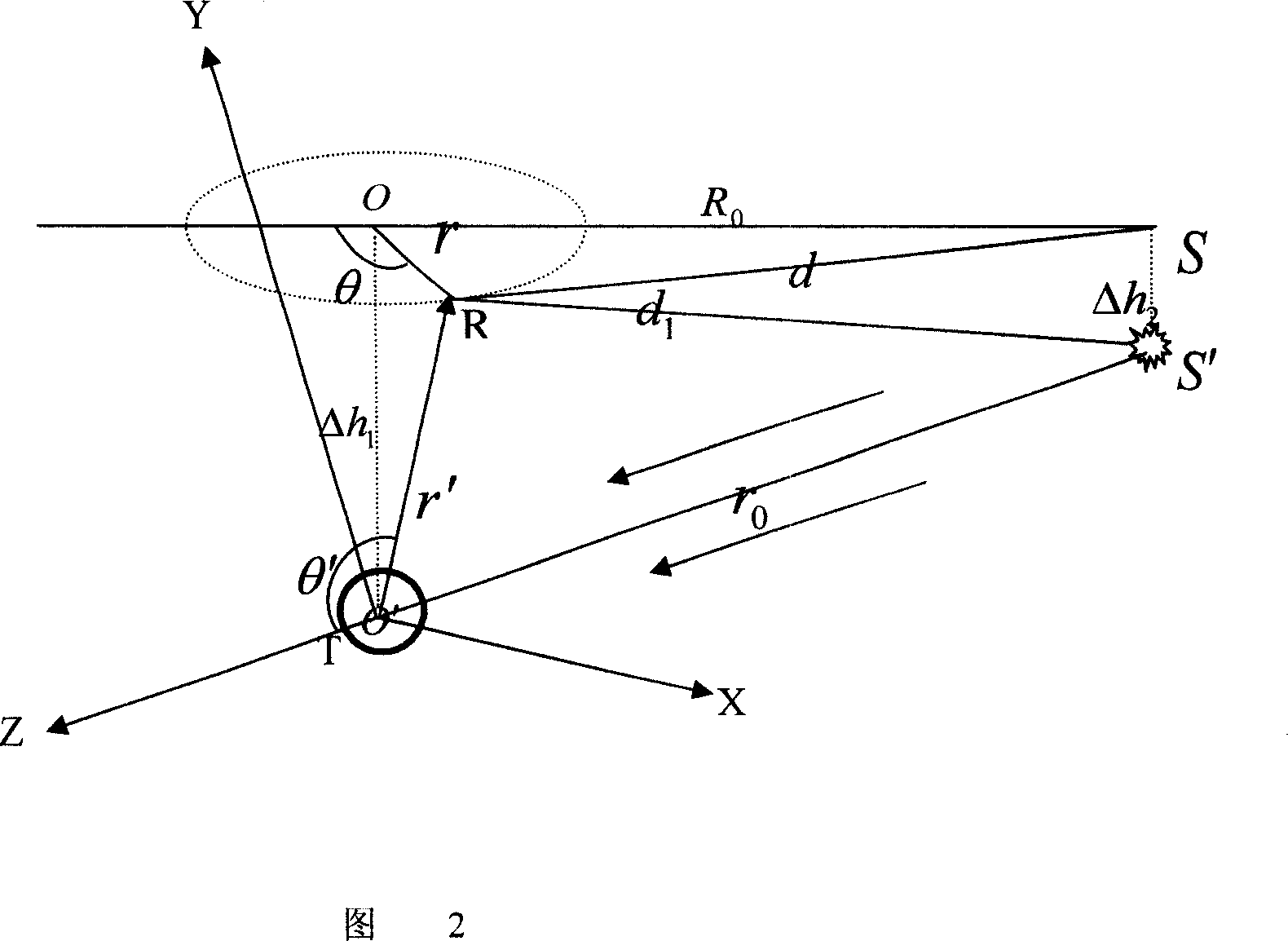

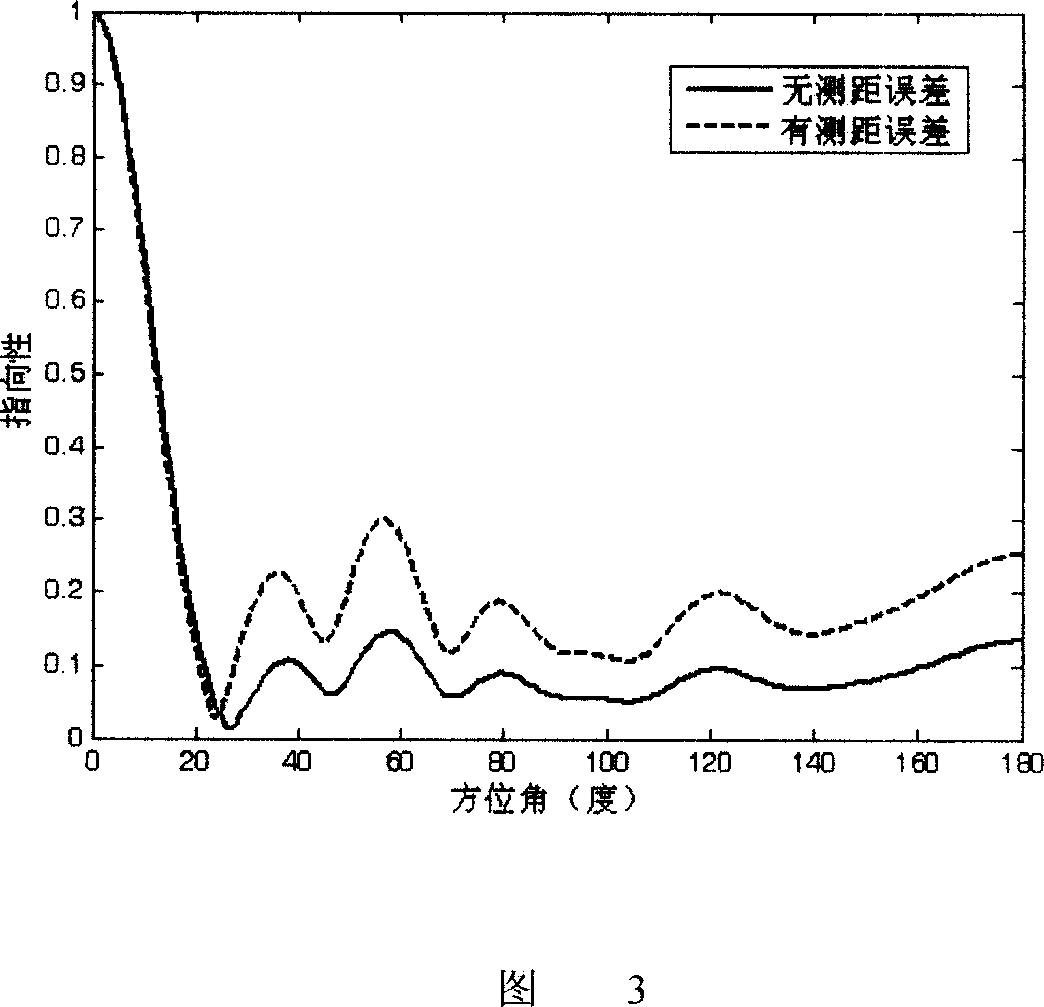

[0053] The target ball is a solid aluminum ball of a certain type, the radius a=0.080m, and the signal source emits a spherical wave with a frequency f=28kHz. Since the loss of metal aluminum is extremely small, the loss factor of its elastic modulus is 1.0×10 -3 or so, its influence on the scattered sound pressure is very small, even negligible, so here it is assumed that α 1 = 0, α 2 =0. distance R 0 = 1.77m, r = 0.95m, carry out the simulation calculation of the scattering field, the solid line in Fig. 3 is the simulation result of the directivity of the scattering field, use this result to obtain the Legendre coefficient and substitute it into the formula (7), use the genetic The algorithm performs par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com