Manufacturing apparatus and method of optical device

A technology for optical devices and manufacturing devices, which is applied to optical components, optics, projection devices, etc., and can solve problems such as complex algorithms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

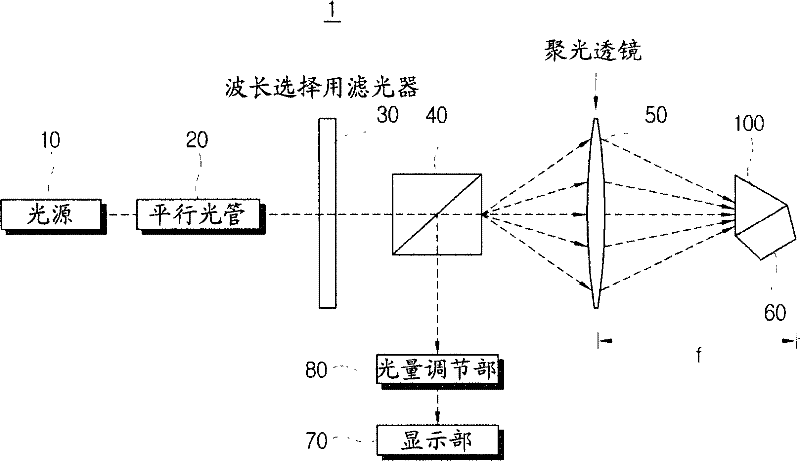

[0028] Refer below figure 1 Referring to FIG. 3 , an optical device manufacturing device provided by an embodiment of the present invention is illustrated.

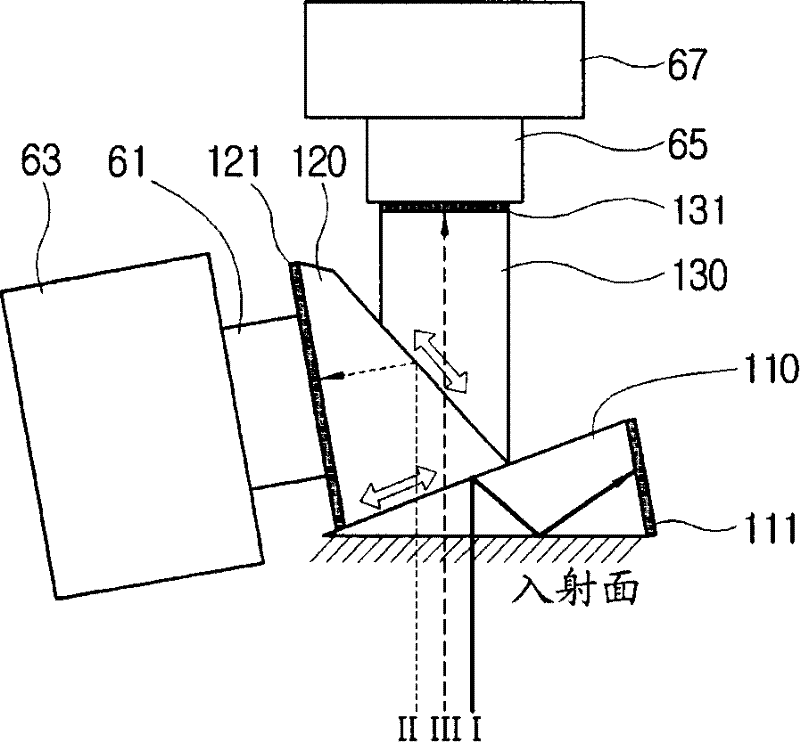

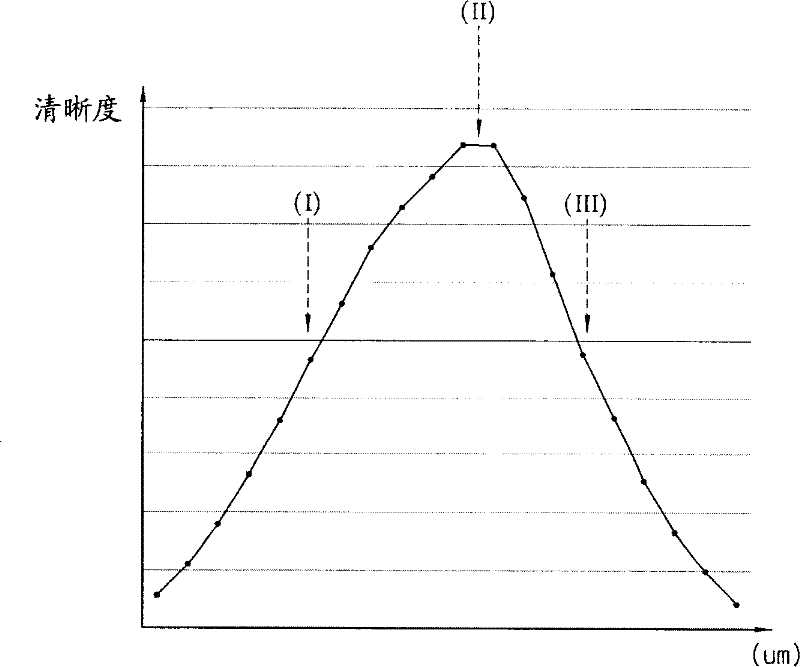

[0029] figure 1 It is a schematic diagram of an optical device manufacturing device provided according to an embodiment of the present invention, figure 2 is a schematic diagram of the prism unit used to illustrate the long optical path length of the prism, Figure 3A and Figure 3B This is a schematic diagram illustrating the change in clarity of light corresponding to the movement of the prism.

[0030] An optical device manufacturing apparatus 1 includes a light source 10, a collimator 20, a wavelength selection filter 30, a light guide 40, a condenser lens 50, a holder 60 for adjusting the position of a prism, and a display for displaying reflected light. part 70 and light quantity adjusting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com