Mining method for replacement of banded coal under building by waste rock

A technology of strip coal pillars and mining methods, applied in underground mining, fillings, safety devices, etc., can solve problems such as low recovery rate and waste of resources, and achieve the elimination of ground gangue, avoid pollution, and reduce air and environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

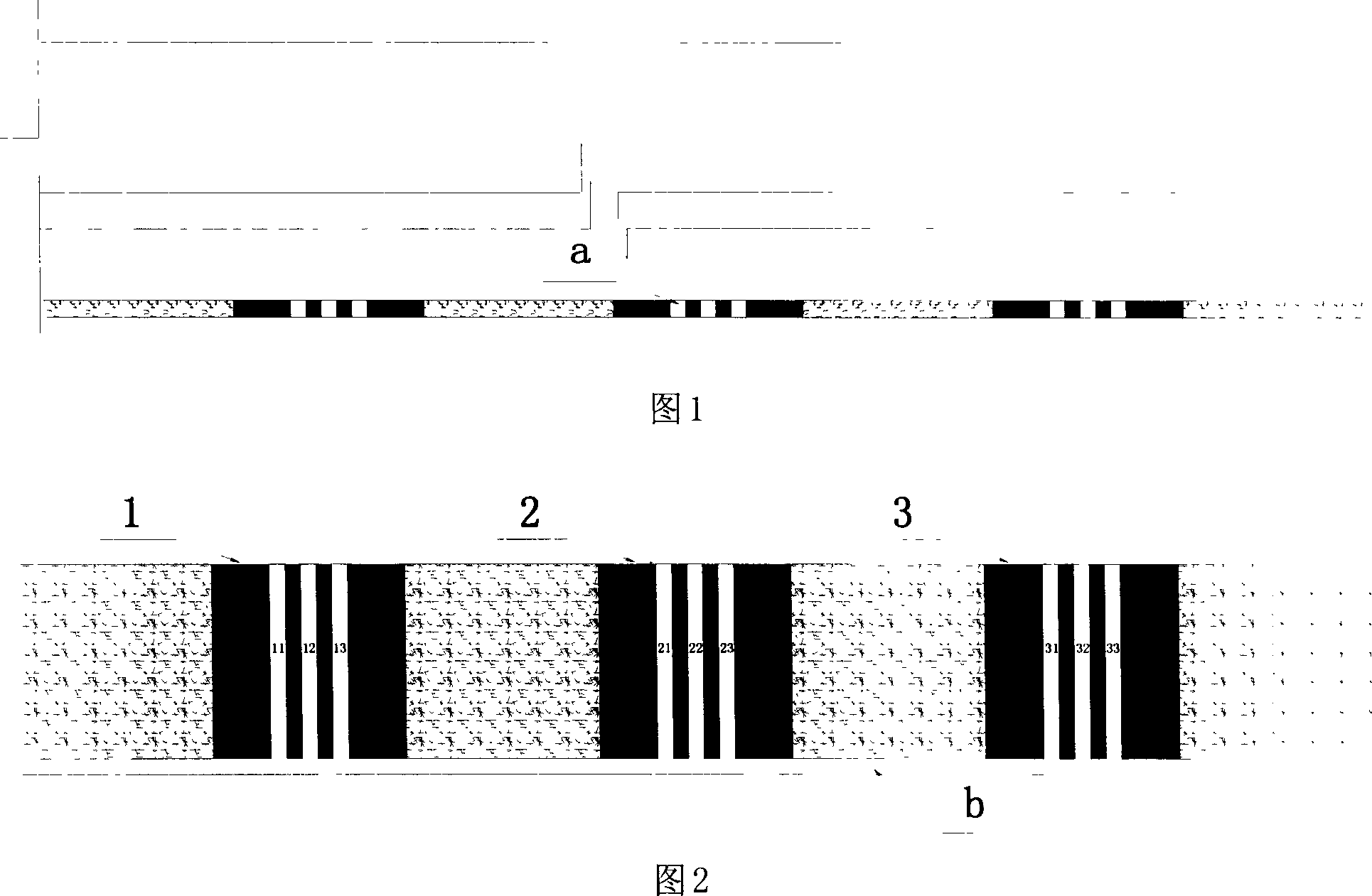

[0017] In the mining method for replacing striped coal pillars with gangue under buildings in the present invention, the gangue filling roadway b is firstly excavated, and after the excavation is completed and the equipment used during the excavation is removed, the gangue filling equipment is arranged gradually from the inside to the outside. Gangue filling treatment. After filling the gangue to fill the main lane, build a wall with cement to seal it. As shown in Figure 1, the burial depth of strip coal pillars 1, 2, and 3 is 290m, and the width is 50m. The protection level required for the overlying rock structure and surface buildings is Class I, and they are arranged in the center of each strip coal pillar. 3 gangue filling lanes d (if the cross section of the filling lane is designed as a rectangle, the width of the lane is generally 3.5-5.0m (the hei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com