Engineer machine

A technology of construction machinery and prime mover, which is applied to the cooling of mechanical equipment, engine components, and engines, can solve the problems of inability to form heat exchanger chambers, increase the number of parts, and increase the number of working hours, so as to improve cooling efficiency, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

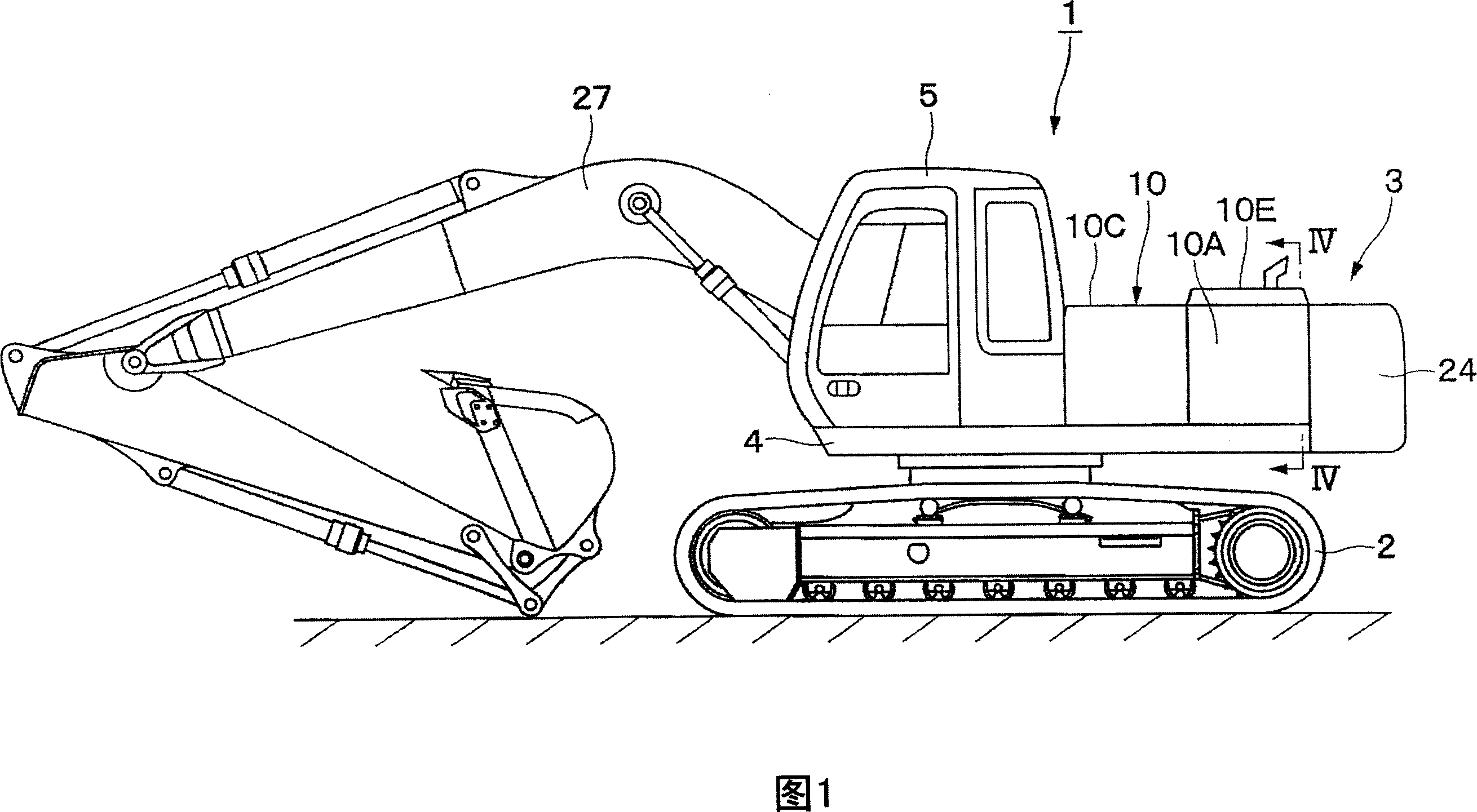

[0054] Hereinafter, a hydraulic excavator equipped with heat exchangers such as a radiator and an oil cooler will be exemplified as a construction machine according to an embodiment of the present invention, and will be described in detail with reference to the drawings.

[0055] First, FIGS. 1 to 15 show a first embodiment of the present invention. In this first embodiment, an example of application to a hydraulic excavator of a standard specification in which the counterweight protrudes more than the undercarriage will be described.

[0056] In Fig. 1, 1 is a crawler-type hydraulic excavator as a construction machine. The hydraulic excavator 1 consists of a self-propelled lower traveling body 2, an upper rotating body 3 rotatably assembled on the lower traveling body 2, and a set The working device 27 described below is configured on the upper revolving body 3 .

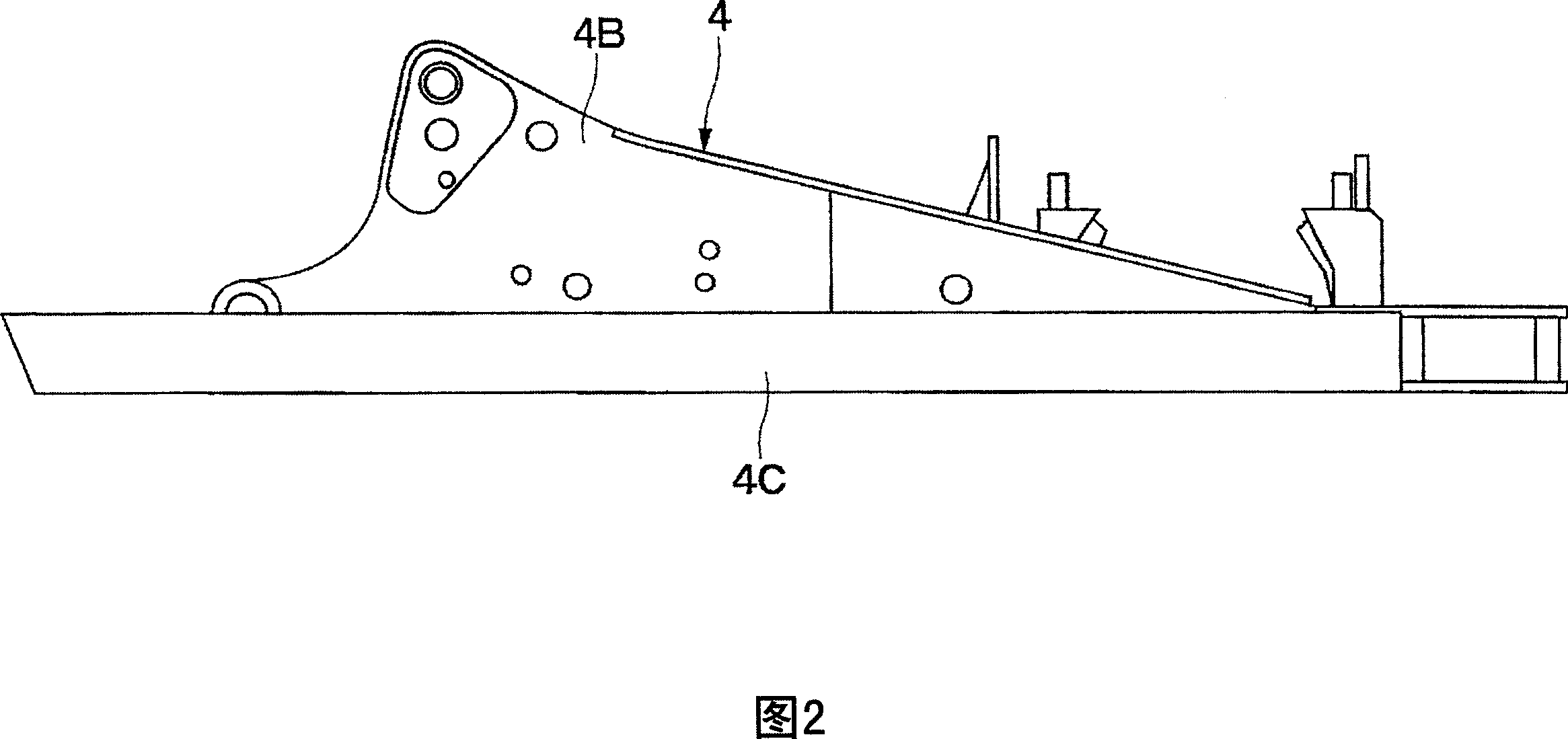

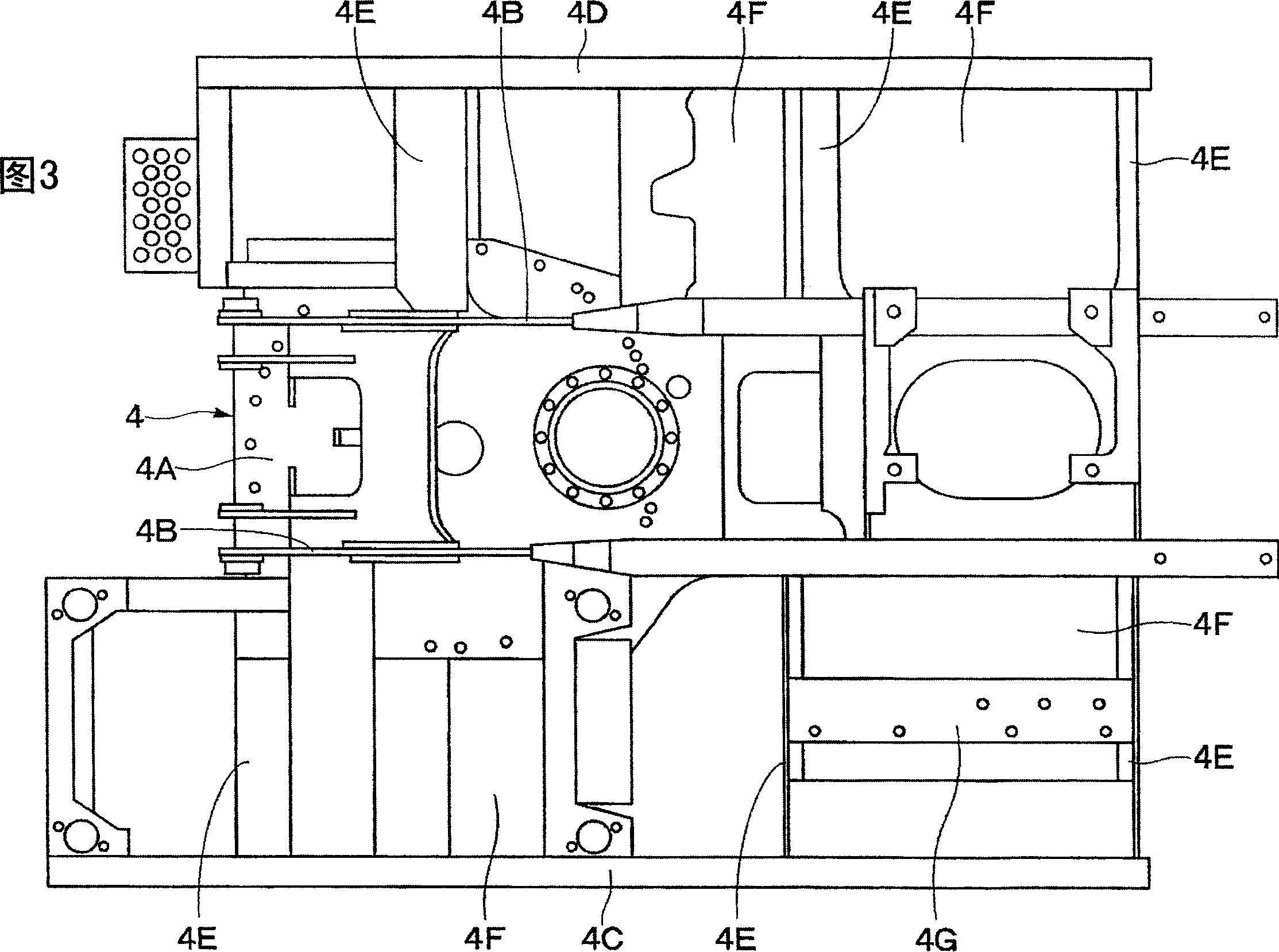

[0057] Reference numeral 4 denotes a revolving frame used as a vehicle body frame constituting the revolving up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com