Method for forming section outline from any section lines in orthogonal surface topography map

A technology of surface topography and cross-sectional profile, applied in measurement devices, instruments, optical devices, etc., can solve problems such as difficulty in expressing cross-sectional profile, influence, and inability to match the length of data points.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

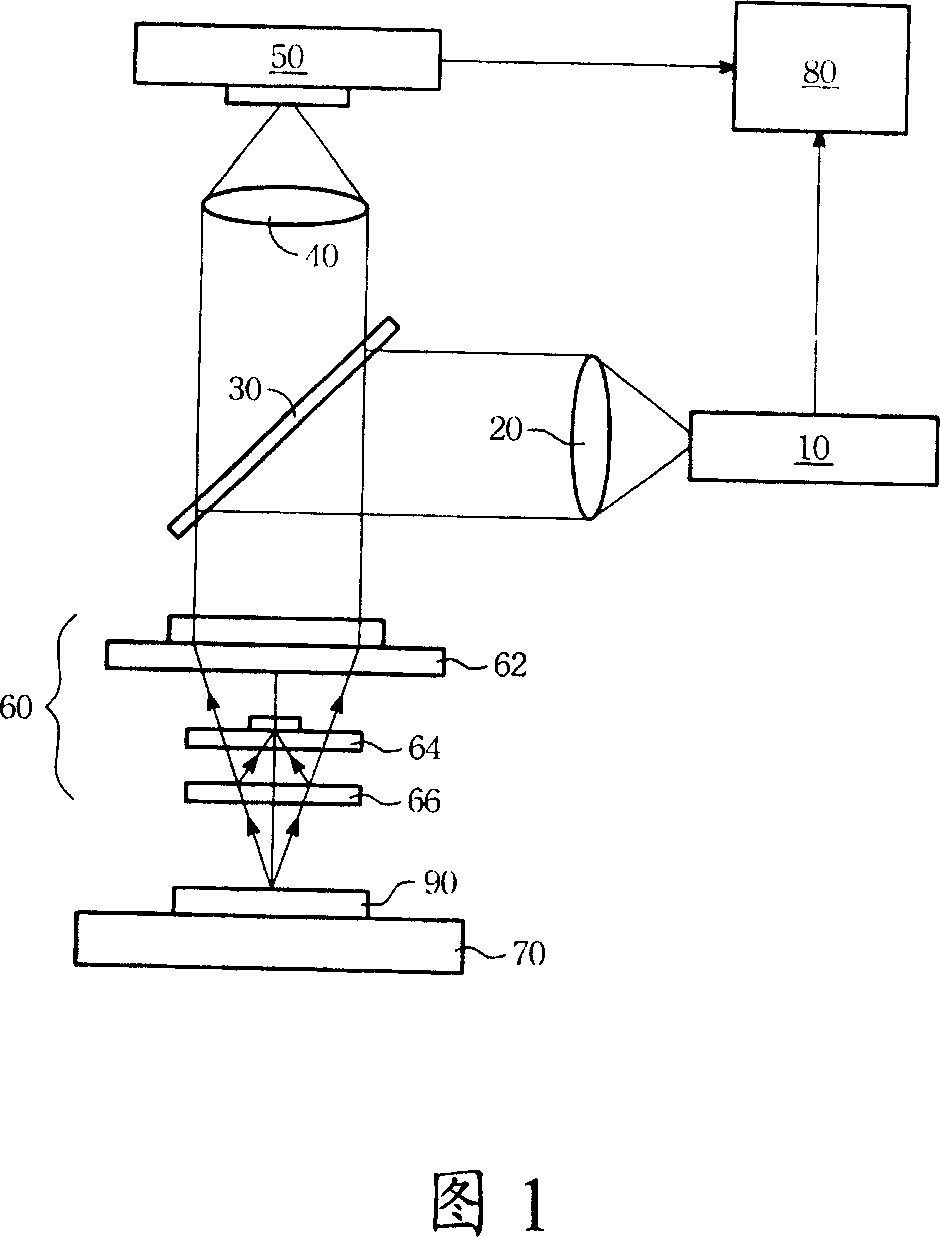

[0033] Below in conjunction with accompanying drawing, illustrate implementation process of the present invention by preferred embodiment:

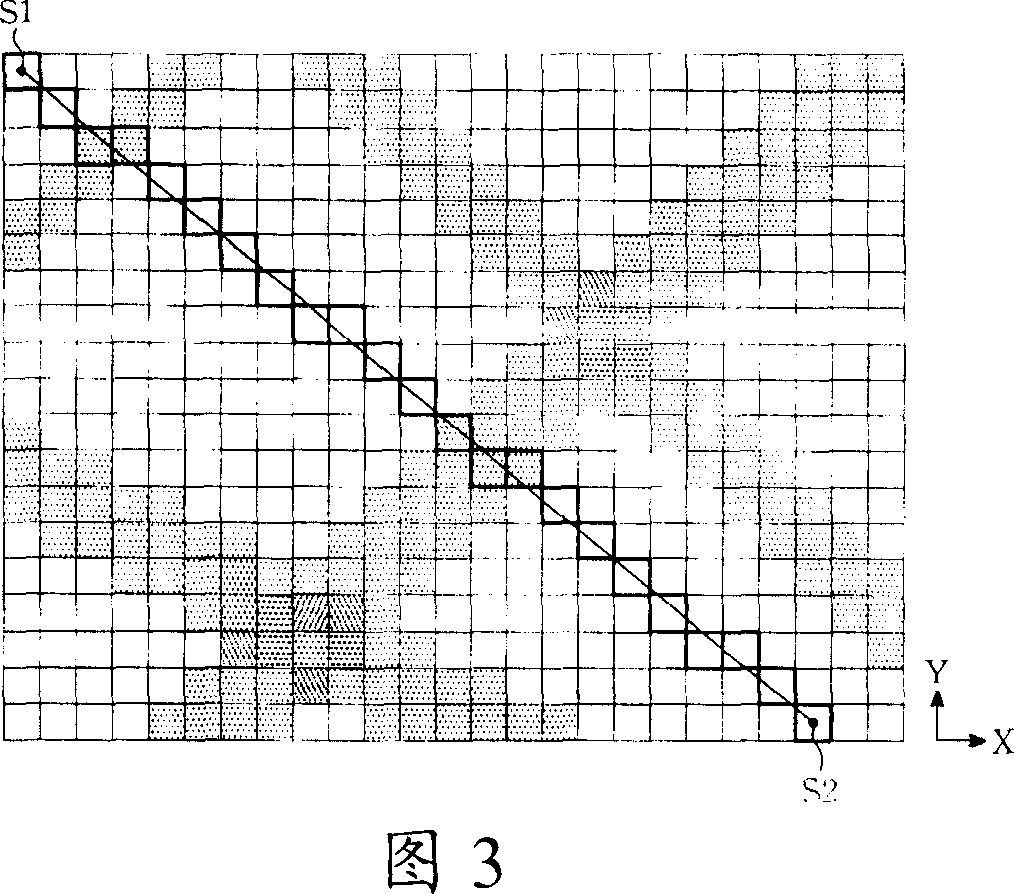

[0034] Please refer to FIG. 4A to FIG. 4D , which are schematic diagrams of a preferred embodiment of the method for forming a cross-sectional profile of the present invention. FIG. 4A is a known surface topography, and the a-a line segment is a section line to form a line profile. The surface topography map is divided into a plurality of orthogonally distributed pixel grids. Each pixel square has its corresponding numerical value to represent the height value.

[0035]First, as shown in FIG. 4B , along the direction of the a-a section line, a column of grids to be tested (that is, the grids indicated by dotted lines in the figure) is established, and the a-a section line runs through the central position of the column of grids to be tested. The side length L of the grid to be tested is equal to the side length S of the aforementioned p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com