Whole stalk complete reclaiming type corn harvester

A corn harvester and straw technology, which is applied to the chassis of harvesters, agricultural machinery, agricultural machinery and machinery, etc., can solve the problems of complex structure of the whole machine, large loss of ear picking, etc., achieve stable chain transmission, reduce grain loss, High productivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

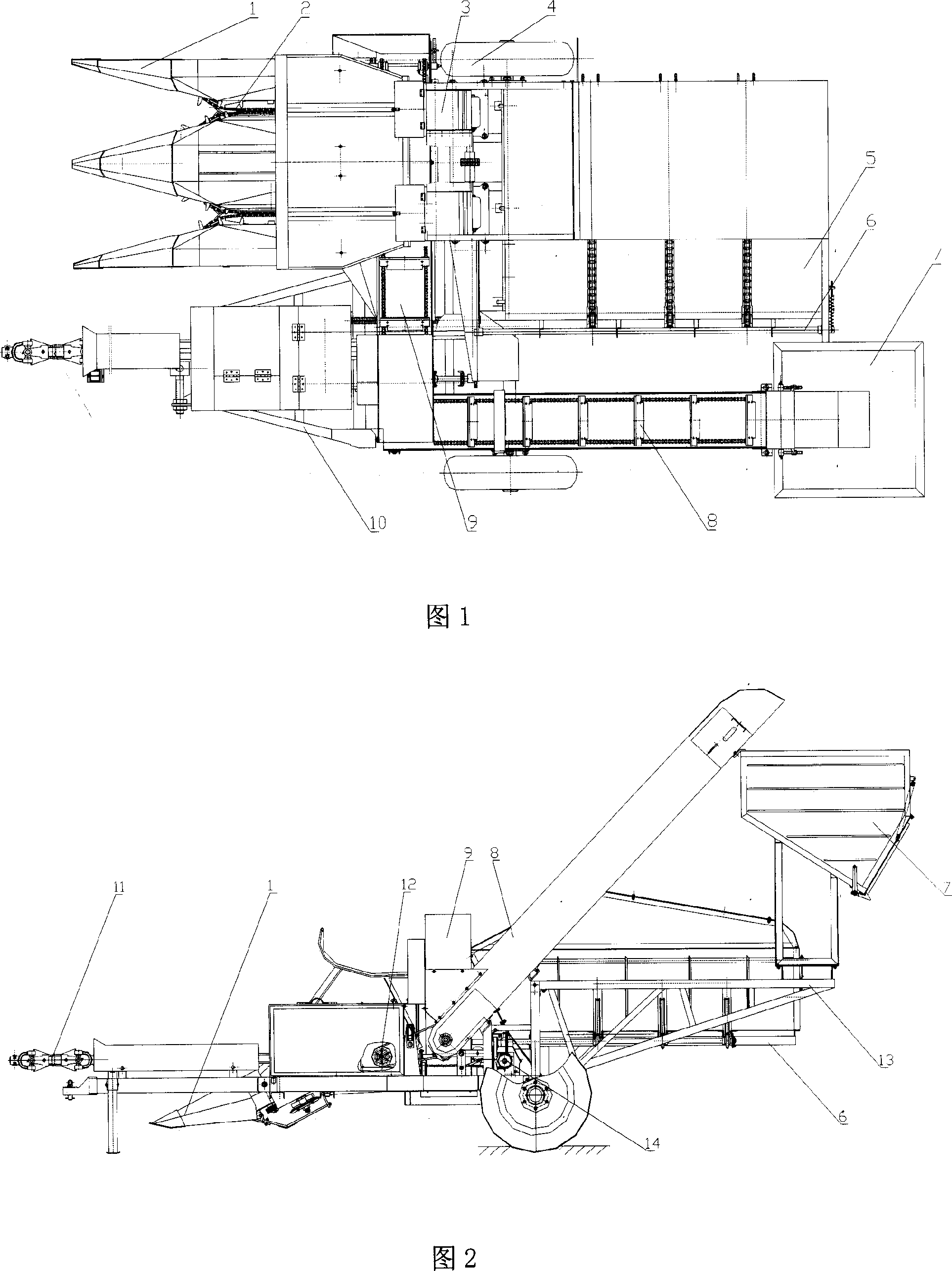

[0024] The straw whole plant recovery type corn harvester is characterized in that: see Figure 1, the equipment consists of a frame 10, a grain dividing part 1, a clamping device 2, an ear picking device 3, a ground wheel 4, a straw stacking platform 5, a retaining Tooth 6, ear box 7, secondary elevator 8, first-level elevator 9 and drive sprocket, belt form; Its power comes from traction tractor.

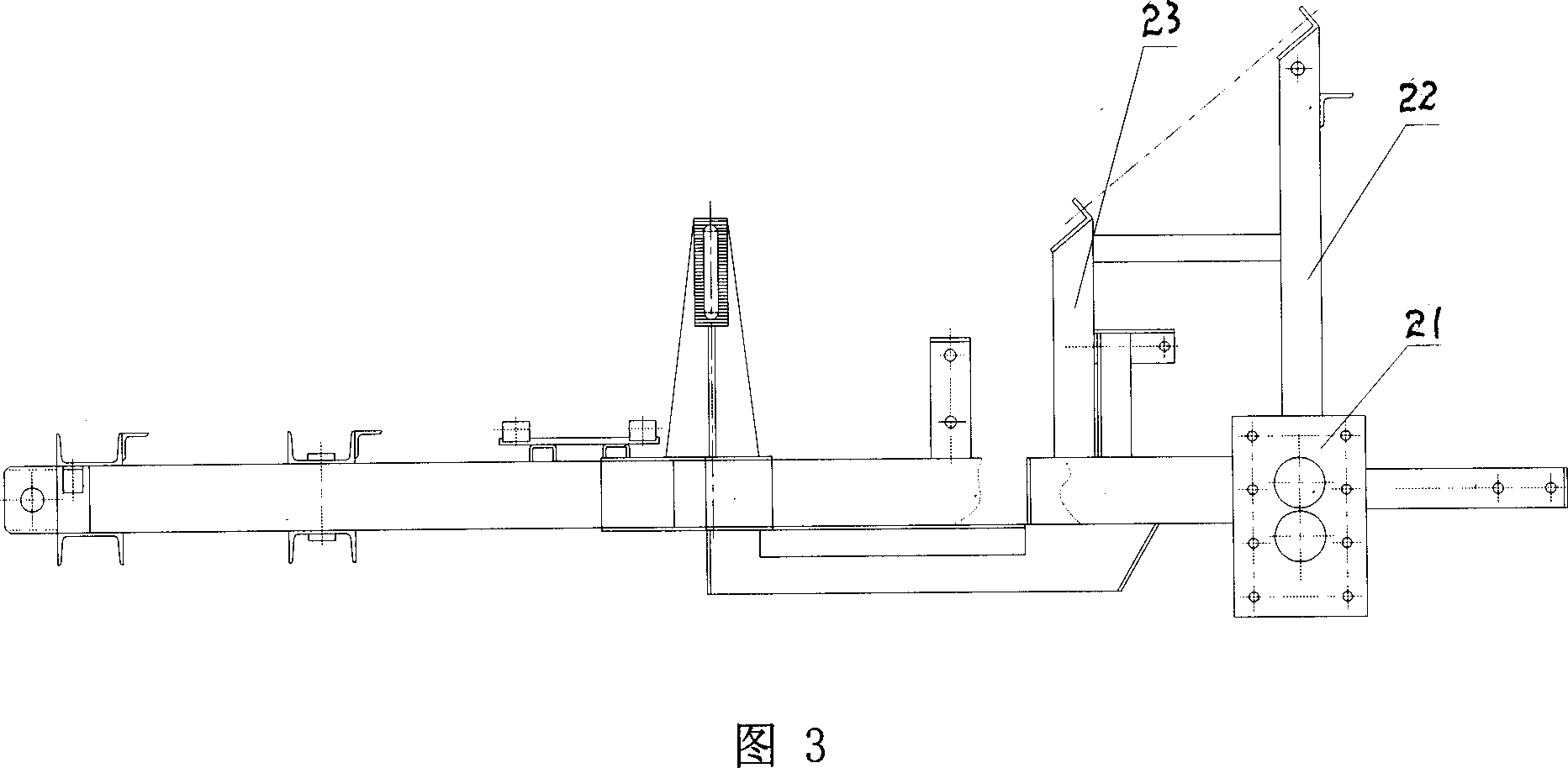

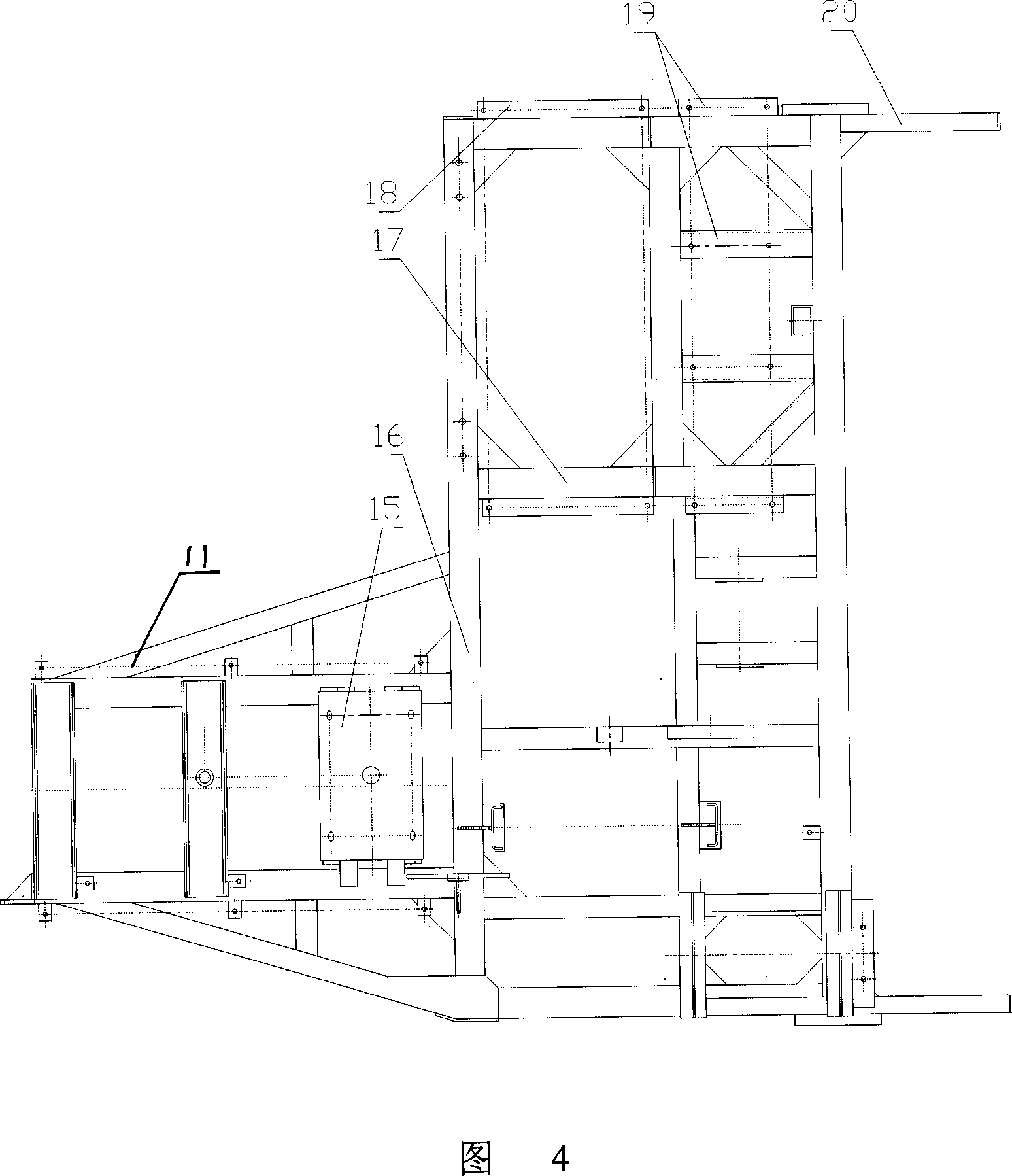

[0025] As shown in Fig. 4, a traction connecting frame 11 is welded in front of the frame 10, and the main gearbox seat plate 15 is welded on the traction connecting frame 11; There are two sets of connection holes with a spacing of 600mm on the right side of the front beam, and the clamping device 2 is fastened to the frame 10 through bolts at the connection holes; on the two longitudinal beams on the right side of the frame, the The rear is respectively welded with a first-level elevator connecting seat 18 and an ear picking transmission box connecting seat 19; see Fig. 3, a seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com