Combination type drilling machine

A combination of drilling rig and drilling tool technology, which is applied in the direction of drilling machines, wood processing equipment, manufacturing tools, etc., can solve the problems of low work efficiency, poor working environment, and poor air circulation, and achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

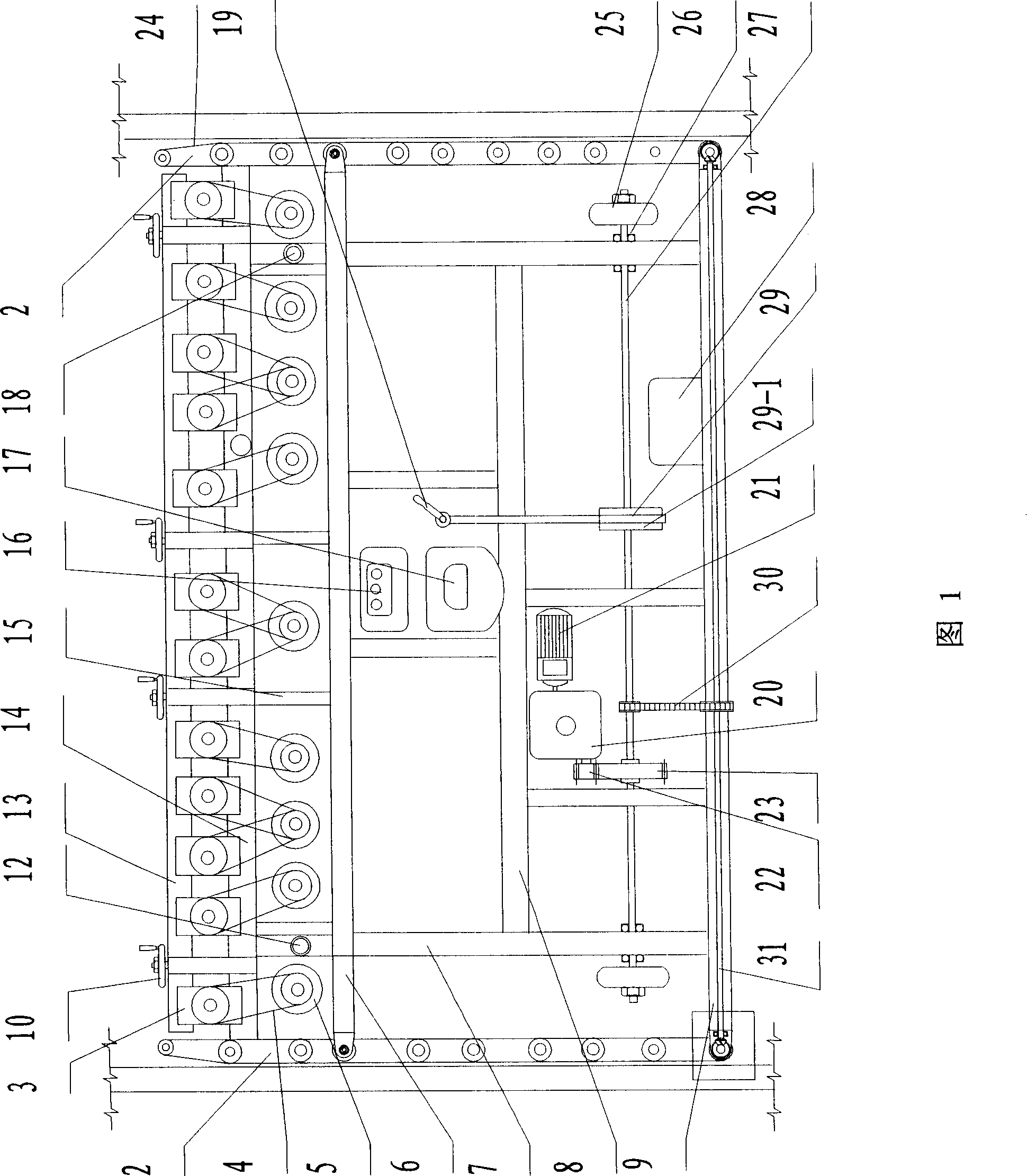

[0021] Such as figure 1 Shown, in the present invention, combined drilling rig comprises base, and this base is welded by two vertical beams 7 and crossbeam 13,14,6,8,9 and 4 connecting plates 15, on base, front crossbeam 14 and There are many drilling tools 3 sandwiched between the beams 13, and the base is also provided with a locking wheel 10 for fixing and clamping the drilling tools 3. According to the quantity and position of the holes to be drilled each time on the container floor, the drilling tools can be adjusted. 3 The number and position can be adjusted arbitrarily.

[0022] A motor 5 that drives the drilling tool 3 through a belt 4 to drive the drill bit to rotate is installed on the base. One of the motors 5 can drive one or more drilling tools 3 . Belt elastic pulleys are all installed on every belt 4, in order to adjust the tightness of belt 4.

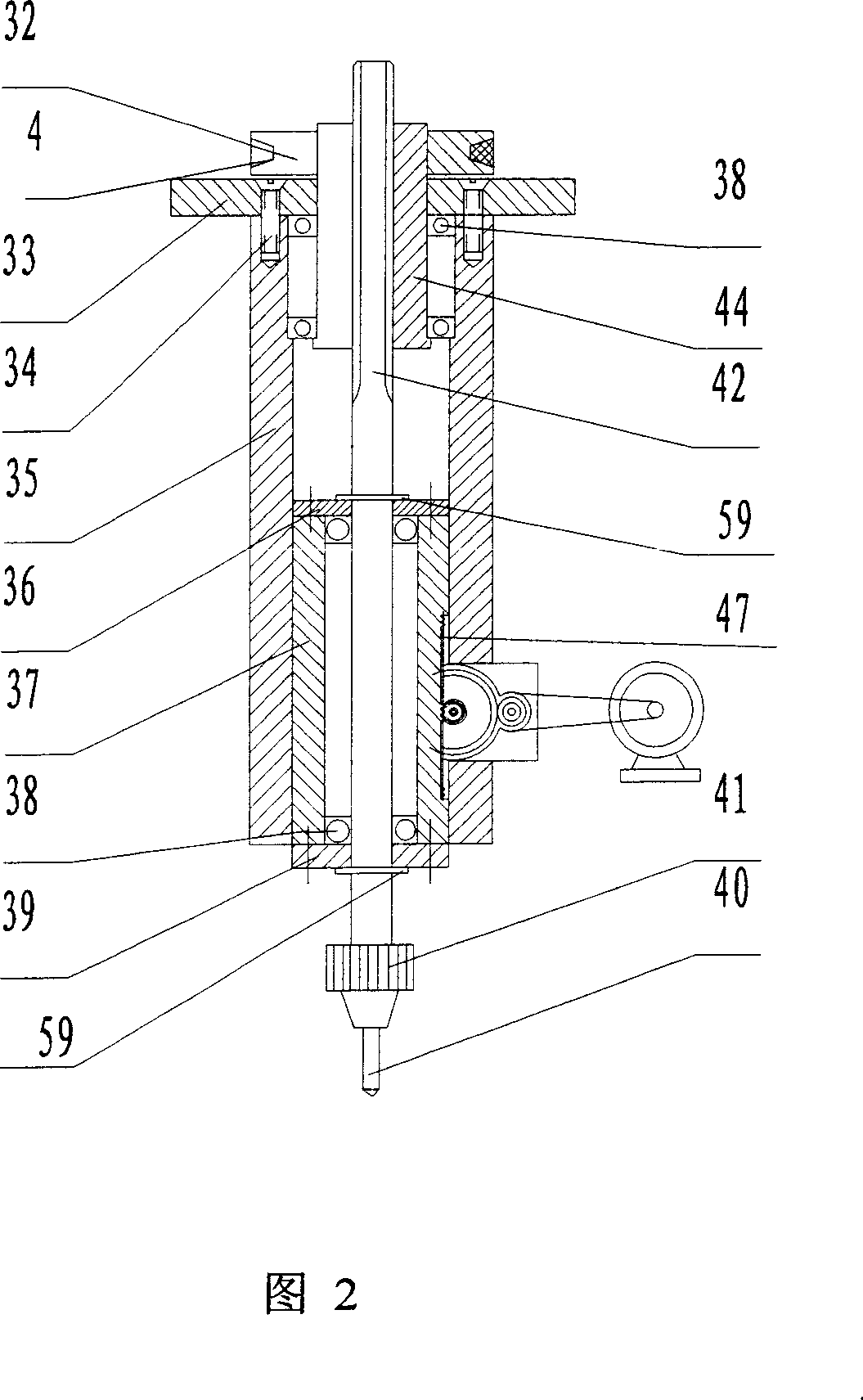

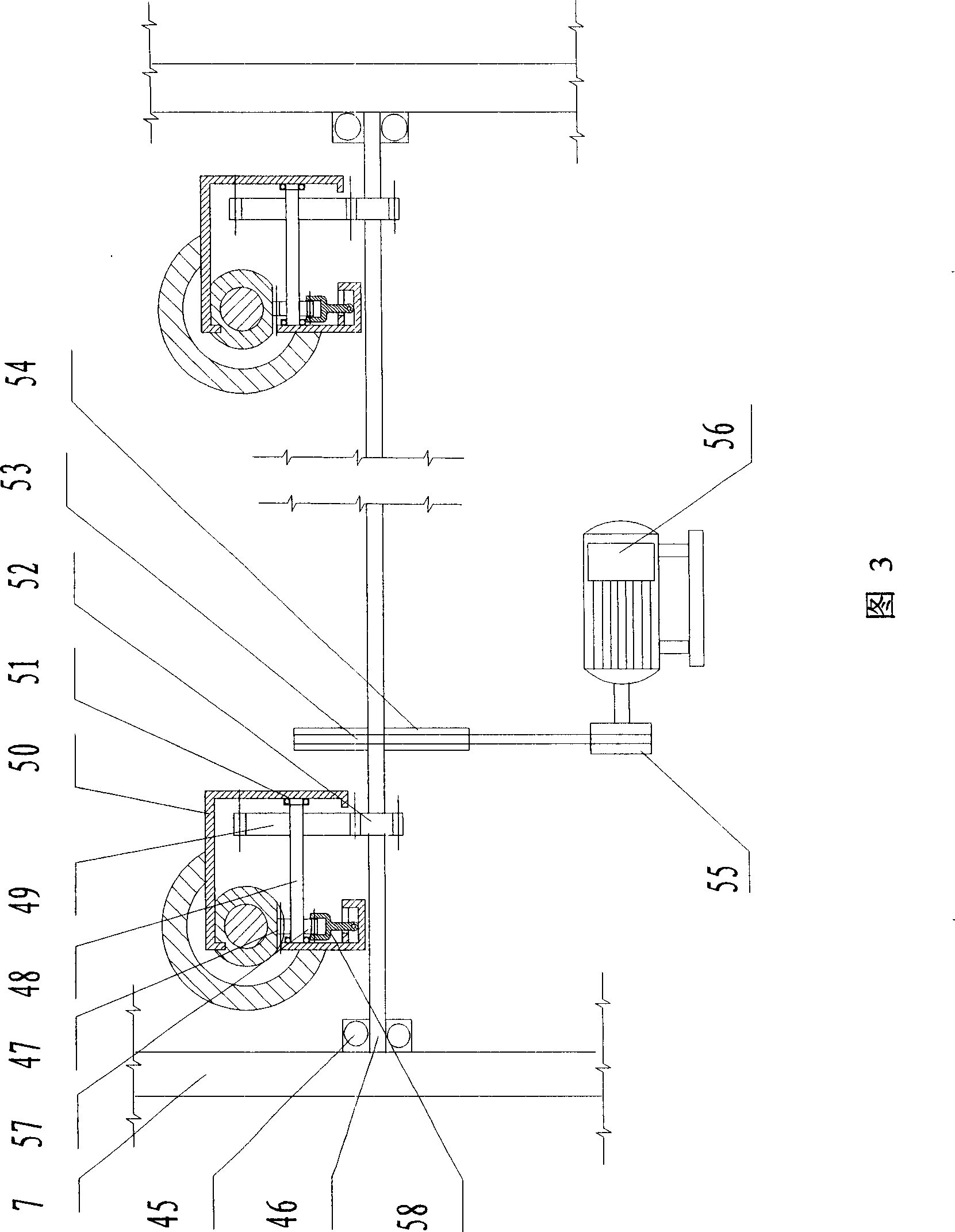

[0023] The drilling system that drives the drilling tool to rotate is realized by the following scheme: such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com